hafmpty

Well-Known Member

Do you see much grain coming through when re-circulating?

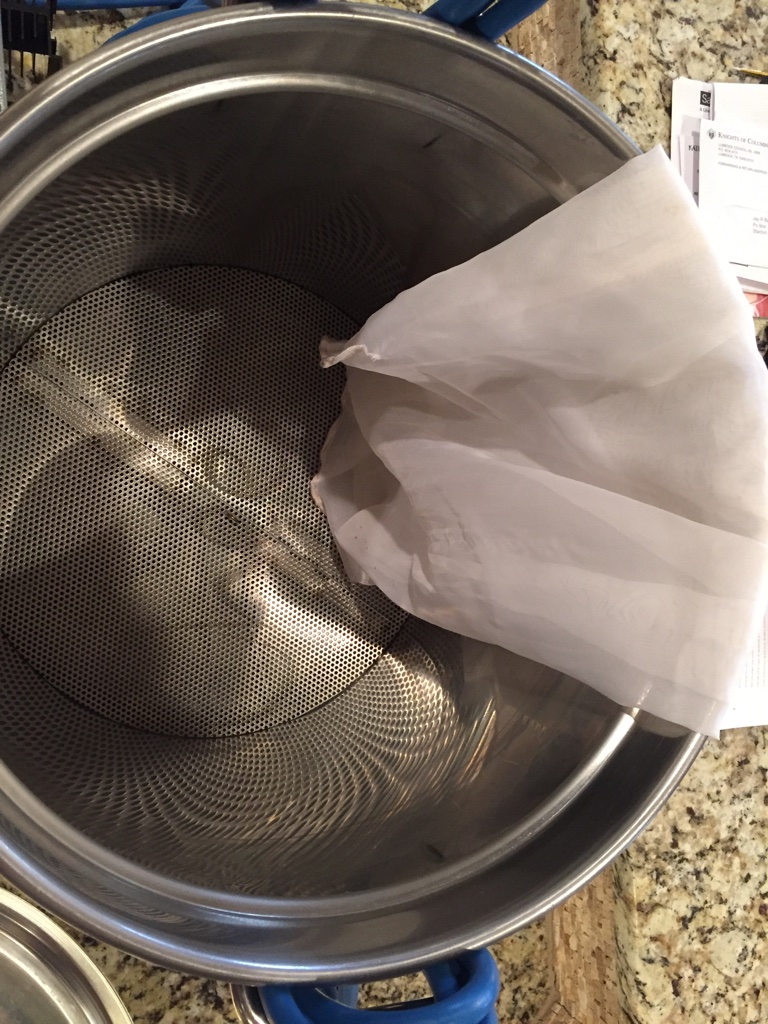

Well the amount of grain is really dependent upon your system. I crush really loose (.050 vs. .008-.010 in some BIAB systems). So my filter bed is more like a traditional system. With the way I brew I don't get any pieces of grain because of my crush and the 400 micron basket that won't let it through. Hope that helps.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)