IamCanadian said:I really like this idea. How is the balance on it when the kettle is full water.

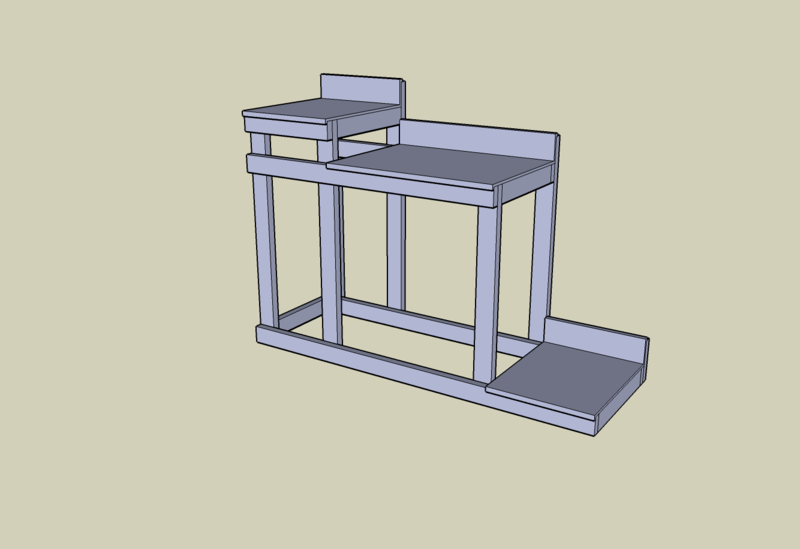

I put the shelf low enough to not cause balance issues but tall enough to drain into fermenter. I brew small batches so never more than 5 gallons in kettle. One could add a drop down support leg to shelf. The cart is heavy and balances nicely.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)