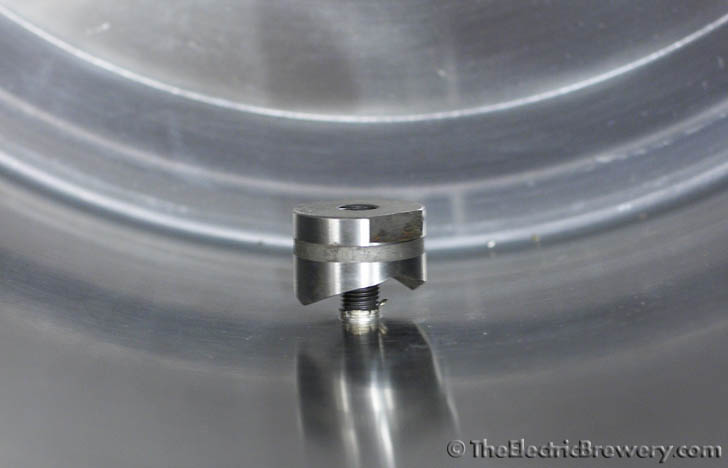

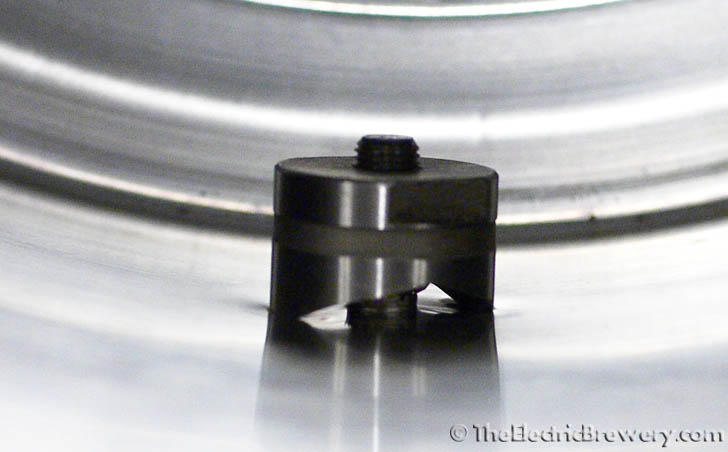

I used Greenlee punches to punch 100% of the holes in my kettle. The side I was pulling the cutter through is perfectly smooth, almost like a factory hole. But the flip side on all of the holes is a bit rough. The holes a perfect in size, shape ect, but just a bit rough on one of the two sides. I was using brand new punches so it was not the issue. Anyone else have this issue? I was debating touching them up with sandpaper, but I was worried I would scratch up the finish on my kettle.

Anyone else run into this??

Anyone else run into this??

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)