augiedoggy

Well-Known Member

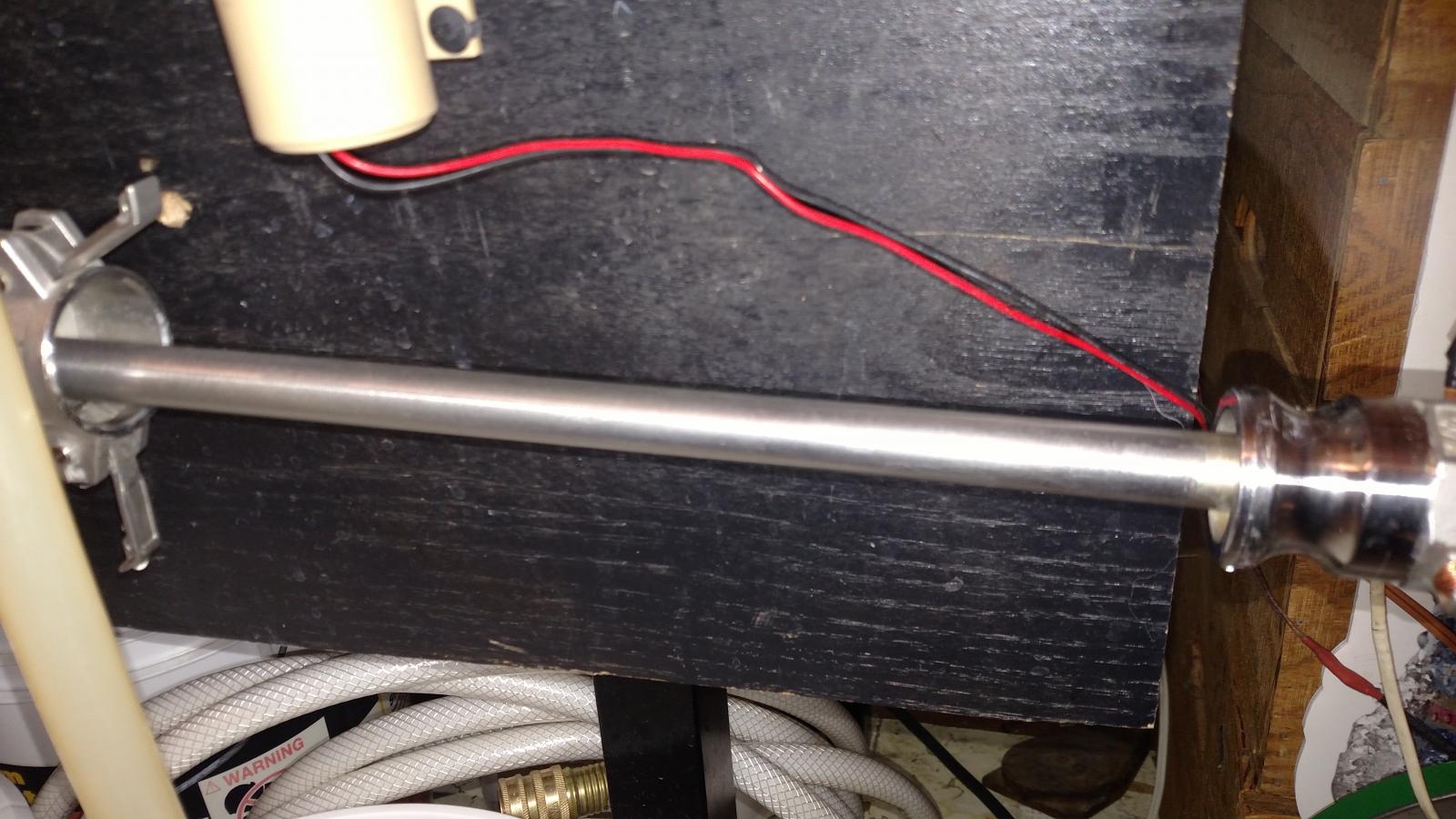

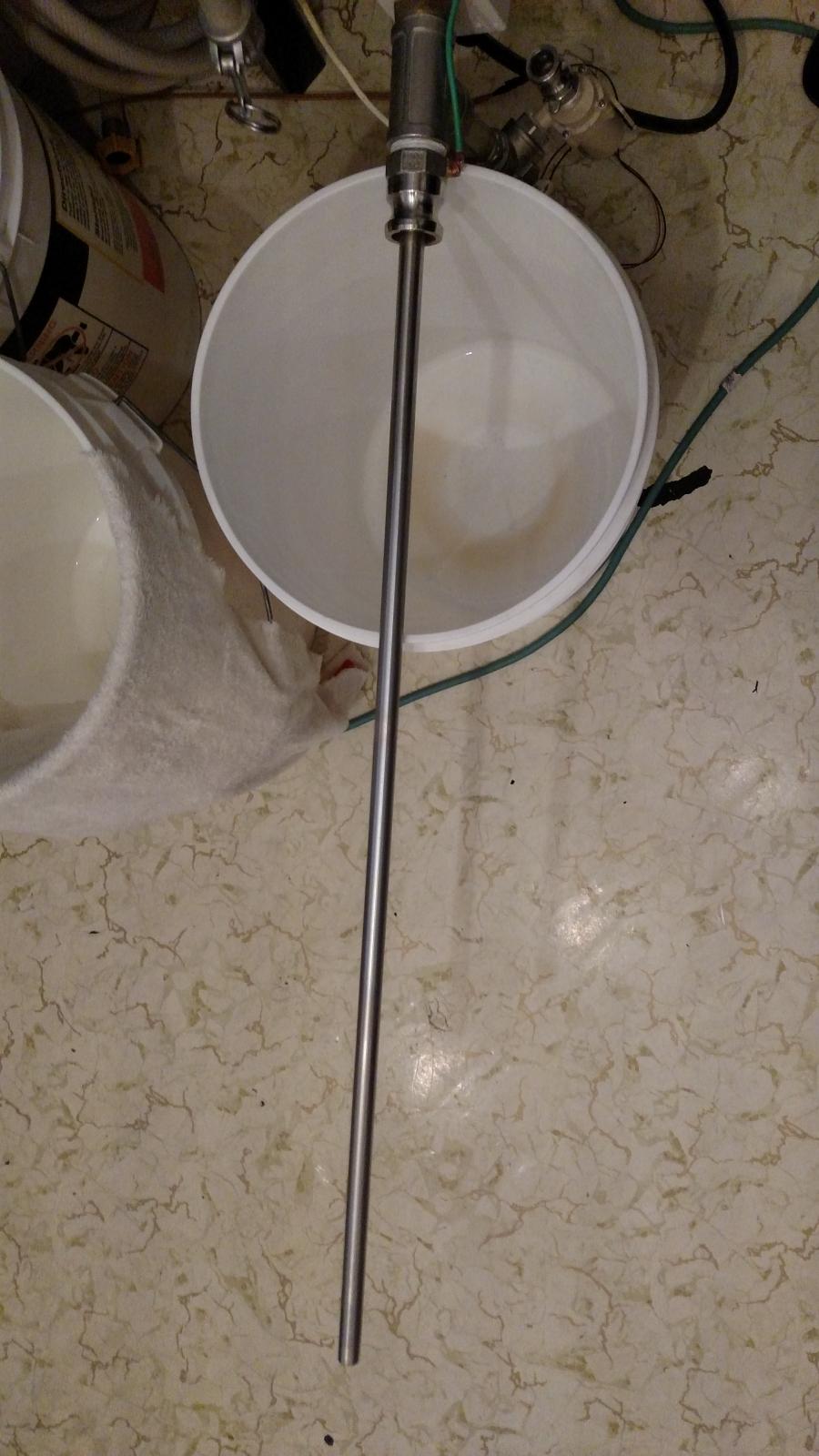

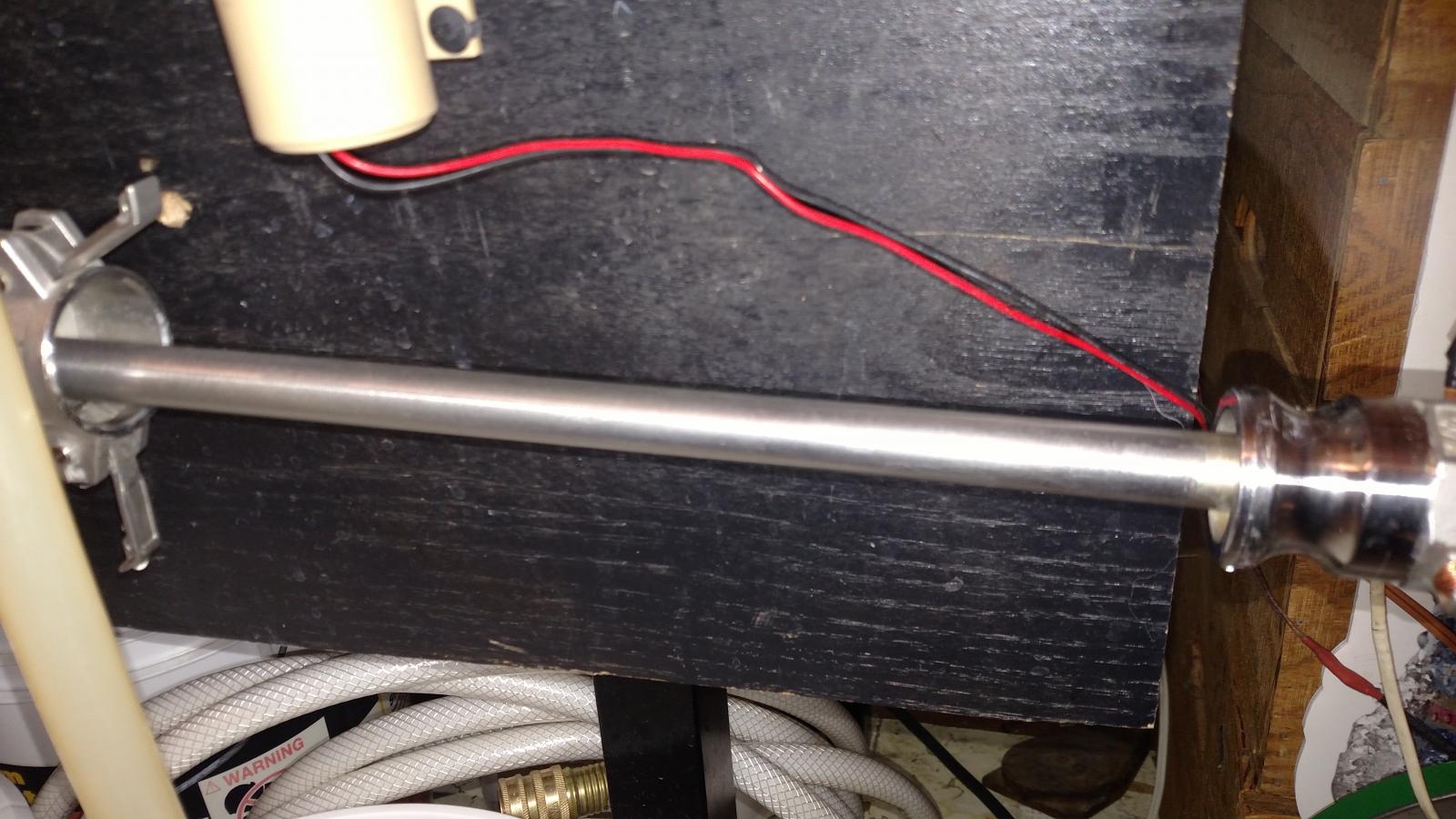

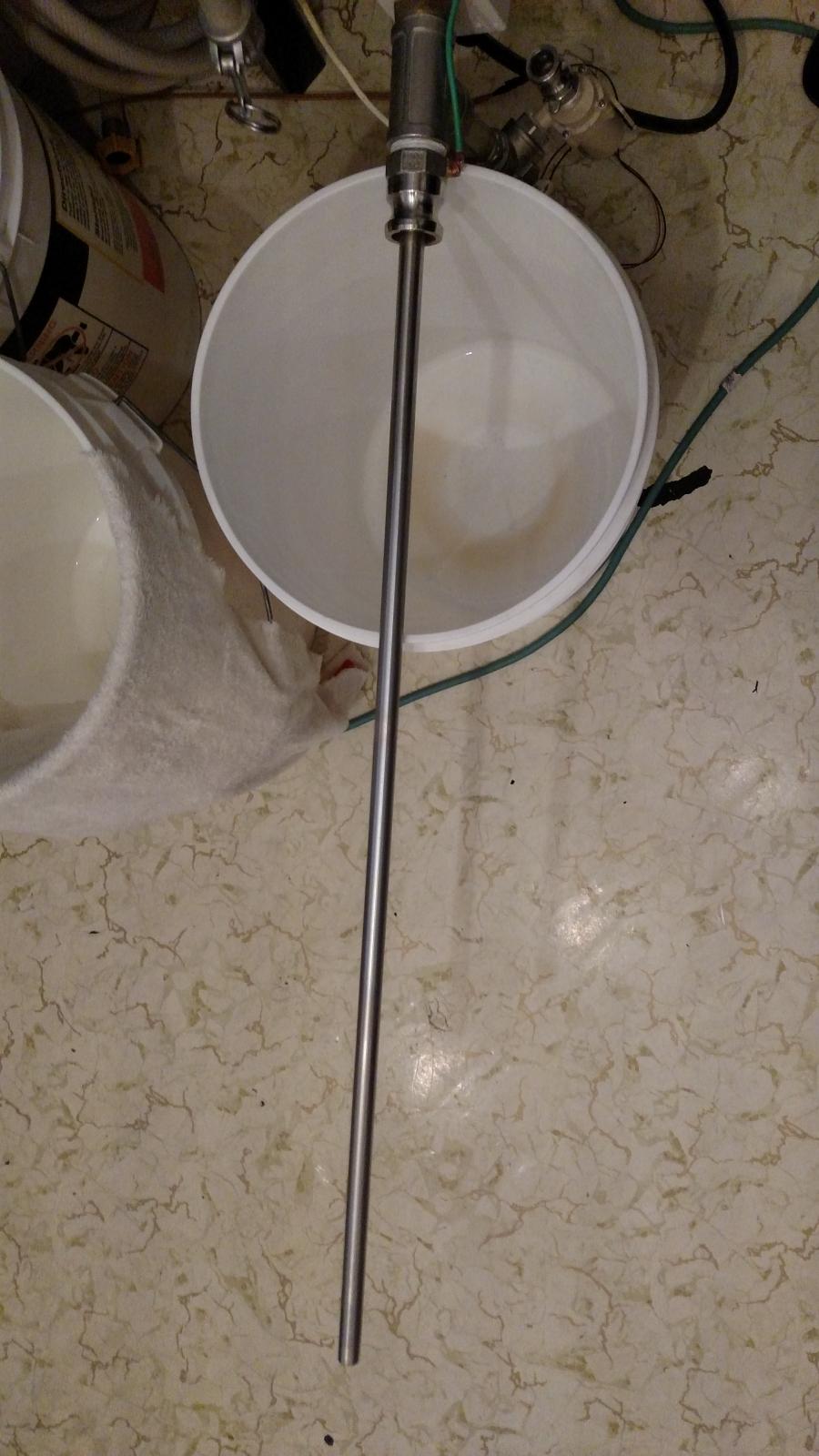

I brewed a Belgian Dubbel last night.. When I finished I ran warm water through my rims and plate chiller for about 20 seconds until I was out of water in my HLT... this is the state of my element directly after brewing with only that 20 second rinse. as you can see its completely clean with no film whatsoever. This is due to the very low watt density. this also eliminates the "shock treatment" Bobby was talking about... I average 86% efficiency on this system all day long so It must be doing something right... The Belgian Dubbel I brewed last night was from Jamil and John Palmers "brewing classic styles" and even though the recipe called for .5lbs of cane sugar on top of the belgian syrup I found I more than hit my numbers without adding it at all.(hopefully its not needed to dry the beer out but im already at the potential for 8.7% abv.)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)