If you are worried about oxygen in your finished beer then pitching the whole starter is not ideal.

We're going to have to disagree on this; I'm not pitching into the finished beer, I'm pitching into the just-created wort. Any oxygen in the starter is simply going to be used by the yeast as it multiplies in the fermenter, no differently than the oxygen that I'm putting into the wort using an oxygen tank and an aeration stone on a wand.

Also using pure O2 to oxygenate your starter wort is unnecessary, if you use a stir plate.

A lot of people argue this, and I don't know why. That wort in the starter begins almost devoid of oxygen; it's been boiled off, which is something the LODO people do to deoxygenate strike water prior to doughing in.

******

Can you produce beer without oxygenating the starter? Sure. I used to do exactly that, before I began to look into the LODO stuff. I began to wonder why I would want to pitch yeast into a starter wort that was devoid of oxygen.

I couldn't think of a reason why that made sense, as the yeast have to wait until the stir plate brings in oxygen, though how quickly that happens isn't clear.

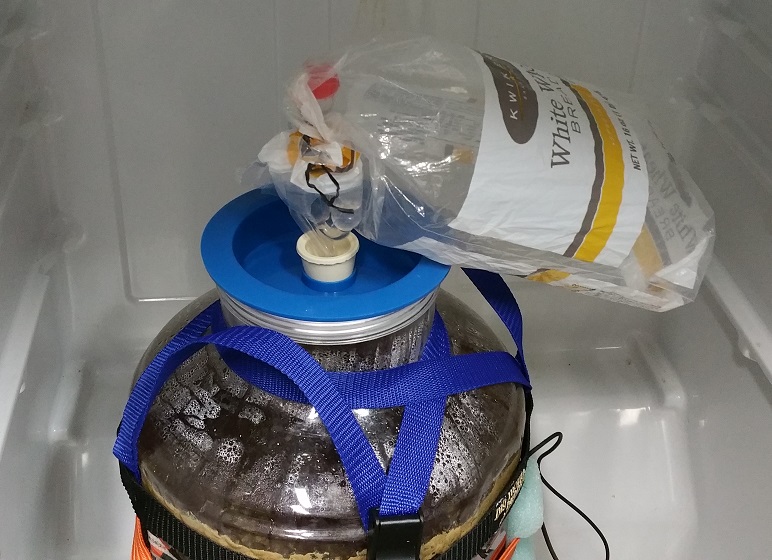

A stir plate constantly introduces oxygen into the starter wort, feeding it the oxygen it needs to obtain healthy yeast propagation. That is the reason for it (propagation), not beer. A stir plate more than doubles the yeast production as opposed to shaking it once in a while. But, one of the side affects of this process is that in addition to nice healthy yeast, you now have a lot of oxygenated, bad tasting, starter beer. You are better off decanting it (cold crashing it first if you have time) and keeping that away from your finished product. I figure the starter is for good yeast, the fermenter is for good beer, I would not pour starter liquid into my beer (I try to get rid of most of it). I do pour the starter beer into another sterile container and let it settle for a couple more weeks, to get the yeast that was still in suspension. I'll freeze this if there is enough (most of the time) or use it to propagate more.

Again, we have to disagree here. A stir plate might or might not be the best way to introduce oxygen; I'm not sure why anyone would oppose the idea of adding oxygen directly so as to get the yeast going as quickly as possible.

***********

As to the starter wort tasting badly, well, that's true; however, it's not carbonated, not conditioned, the yeast hasn't had any time to clean up after itself, and most interesting of all, when people add DME into a wort, they're setting up exactly the same thing, i.e., yeast will convert DME to alcohol. What's different? Nothing I can see.

Now, it's possible there's something here I'm not seeing, as I don't know everything there is to know about brewing, but I cannot see where this is a bad idea, and I can see a lot of reasons why it's a good idea.

***********

I've noted above in this thread the advantage to a fast takeoff of yeast: it has the best chance of outcompeting any nasties that get into the wort.

The same could be said for starters.

Now, if you don't want to believe any of this, that's fine. You can do what you want, and it won't have any effect on my beer. And I'll do what I want, and do that knowing that I've had friends who want to buy my beer, produced with my starter protocol, at commercial prices, and a local person who wants me to brew so she can sell my beer in her bar.

I am thinking that if what I do is so bad, I wouldn't have that kind of feedback. And at least to this point, I think it not only isn't bad, it's preferable to do it this way. Yeah, it's a little more of a pain, but I'm more about the beer than I am the supposed pain.

YMMV.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)