tydaddy

Member

- Joined

- Aug 2, 2017

- Messages

- 23

- Reaction score

- 2

Alright guys, this is my first post. I’m going insane – so please help me out! I’m on my 4th attempt at having no foam. It’s been 2 months, a half barrel, and a sixtel of pure foam.

Here was my initial set up…

Krome ss couplers

90 degree ss 3/16 tailpieces

20ft of 3/16 atp vinyl tubing

90 degree ss 3/16 tailpieces

Tapright ss flow control faucets

At first I had an air cooling set up into my tower. Quickly realized that the freezer couldn’t keep up. Switched everything to liquid cooling with water in the same freezer as the beer. Quickly realized that I couldn’t get the water bath cold enough. I then switched everything to glycol cooling in a separate fridge.

After I got my temps stabilized, I started messing with pressures, using everything I’ve read in the forums, every single calculator on the interwebs. Nothing has worked. I’ve tried everything from 3psi up to 40 psi in 2 psi increments. Each day I let it 24 hours. Pure foam no matter what pressure.

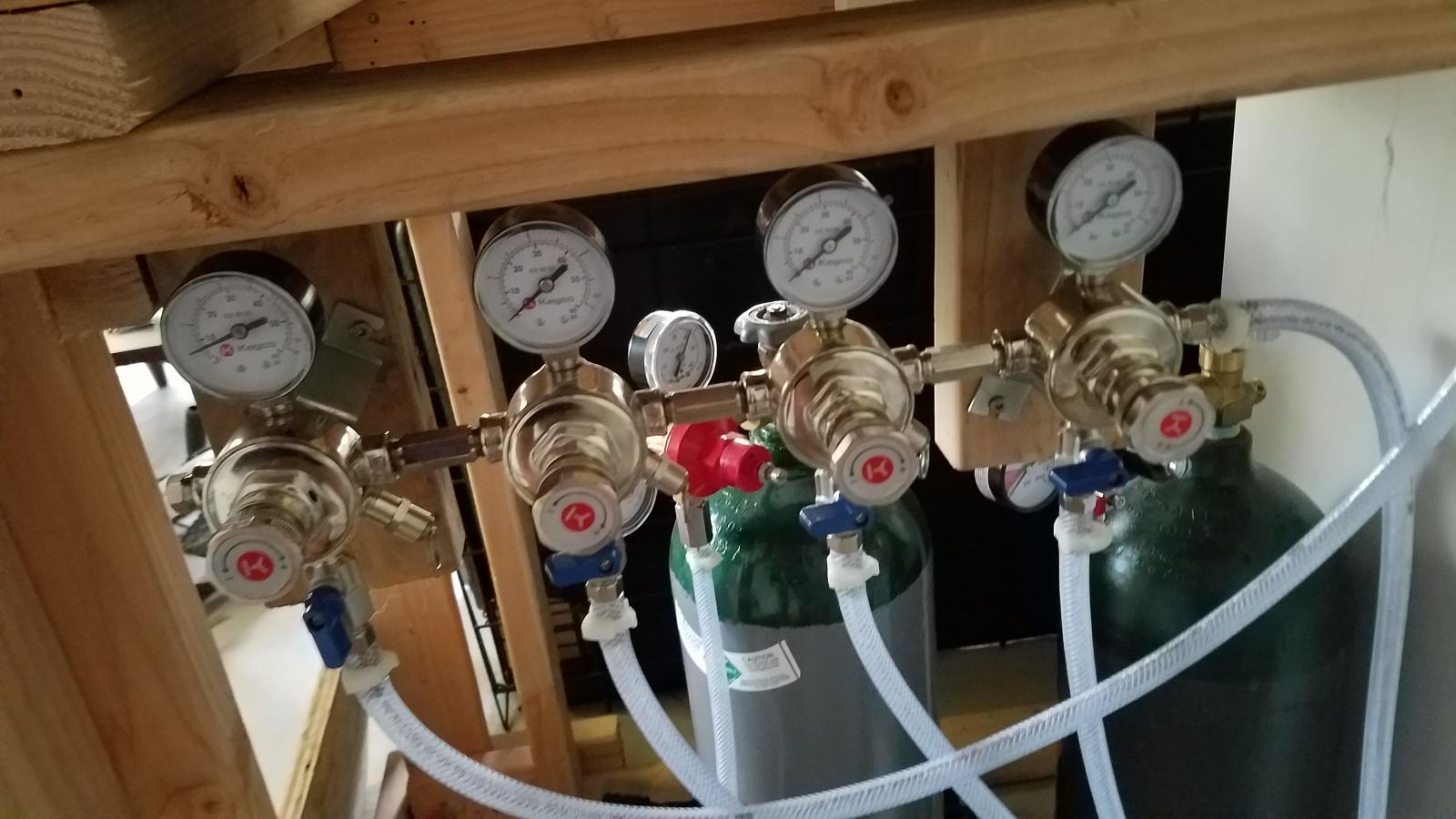

I decided to change the lines from 3/16 atp vinyl, to ¼ bev seal. Also, changed to ¼ ss elbows at the couplers and the shanks. Also, got micromatic ss couplers instead of the Krome. In the process I also decided I also increased the cooling to my taps by wrapping 3/8 OD copper tubing around the shanks, and to run the glycol through that as well.

Even after all of this, I’ve still got all foam. The half barrel was a light lager, the sixtel was perpetual. Both commercial kegs. I’m wondering if all of the pressure changes within the kegs, have rendered them useless at this point. Anyhow, I’m going to post pics below. Also, the towels in the tower are around the copper because they actually froze because there was so much condensation. If you also have any suggestions how to insulate the tower at this point, it’d be great.

My trunk line is 5/16 ID braided vinyl, the ¼ bev seal lines taped to the cold line, return line beside the cold line, all plastic wrapped, then insulated foil tape wrapped, then pipe insulation. I have a thermometer sort of wrapped in the very end up by the tower, just to give an idea of the temp of the coolant right before entering the tower – although, it’s either not in contact with the cold line, or not insulated enough because it’s showing 40deg, when the coolant bath is 30.

One last note. I have it set up so that my half barrel is in the old kegerator, the sixtels will be in the upright freezer. I combine the line from the kegerator as soon as it comes out, into the trunk line. My initial tower design was for the air cooling, one side in, one out. Obviously, the setup has changed, but I haven’t quite worked out a tower design yet. I wanted to make sure I had good pouring beers first – since I’m so frustrated, I want to take the entire damn setup out back and burn it down!!!!

Any help or suggestions would be great, as I’m at an absolute loss right now.

Thanks!

Tyler

Here was my initial set up…

Krome ss couplers

90 degree ss 3/16 tailpieces

20ft of 3/16 atp vinyl tubing

90 degree ss 3/16 tailpieces

Tapright ss flow control faucets

At first I had an air cooling set up into my tower. Quickly realized that the freezer couldn’t keep up. Switched everything to liquid cooling with water in the same freezer as the beer. Quickly realized that I couldn’t get the water bath cold enough. I then switched everything to glycol cooling in a separate fridge.

After I got my temps stabilized, I started messing with pressures, using everything I’ve read in the forums, every single calculator on the interwebs. Nothing has worked. I’ve tried everything from 3psi up to 40 psi in 2 psi increments. Each day I let it 24 hours. Pure foam no matter what pressure.

I decided to change the lines from 3/16 atp vinyl, to ¼ bev seal. Also, changed to ¼ ss elbows at the couplers and the shanks. Also, got micromatic ss couplers instead of the Krome. In the process I also decided I also increased the cooling to my taps by wrapping 3/8 OD copper tubing around the shanks, and to run the glycol through that as well.

Even after all of this, I’ve still got all foam. The half barrel was a light lager, the sixtel was perpetual. Both commercial kegs. I’m wondering if all of the pressure changes within the kegs, have rendered them useless at this point. Anyhow, I’m going to post pics below. Also, the towels in the tower are around the copper because they actually froze because there was so much condensation. If you also have any suggestions how to insulate the tower at this point, it’d be great.

My trunk line is 5/16 ID braided vinyl, the ¼ bev seal lines taped to the cold line, return line beside the cold line, all plastic wrapped, then insulated foil tape wrapped, then pipe insulation. I have a thermometer sort of wrapped in the very end up by the tower, just to give an idea of the temp of the coolant right before entering the tower – although, it’s either not in contact with the cold line, or not insulated enough because it’s showing 40deg, when the coolant bath is 30.

One last note. I have it set up so that my half barrel is in the old kegerator, the sixtels will be in the upright freezer. I combine the line from the kegerator as soon as it comes out, into the trunk line. My initial tower design was for the air cooling, one side in, one out. Obviously, the setup has changed, but I haven’t quite worked out a tower design yet. I wanted to make sure I had good pouring beers first – since I’m so frustrated, I want to take the entire damn setup out back and burn it down!!!!

Any help or suggestions would be great, as I’m at an absolute loss right now.

Thanks!

Tyler

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)