mcgimpkins

Well-Known Member

- Joined

- Feb 23, 2014

- Messages

- 201

- Reaction score

- 56

I've brewed 10-15 beers with this setup and have not run into any electrical problems until this. I started heating up my strike water in the garage, and walked away. I was grinding grains and talking to the wife when I heard a loud pop and the pump shut off in the garage.

Immediately upon entering the garage, I smelled electrical burn and burned plastic. I saw smoke coming from the wire above my GFCI, went to my breaker box and made sure the power was off, the 30 amp breaker had flipped. I unplugged everything, however I had to wear gloves to unplug the NEMA L6-30 from my inline GFCI, as it was too hot to touch. I got my camera to document it and have drawn up a wiring diagram. I had to use pliers to pull apart the NEMA L6-30 as the plastic had completely melted.

Has this happened to anyone? Do you think I had a loose wire? A faulty NEMA L6-30? I am not an electrician, however from everything I have read states I have wired my setup correctly.

At the moment I am not really sure what I can do and if I can salvage the NEMA L6-30 plug on the GFCI as it has a bunch of melted plastic on it.

See Pics below:

Wiring Diagram

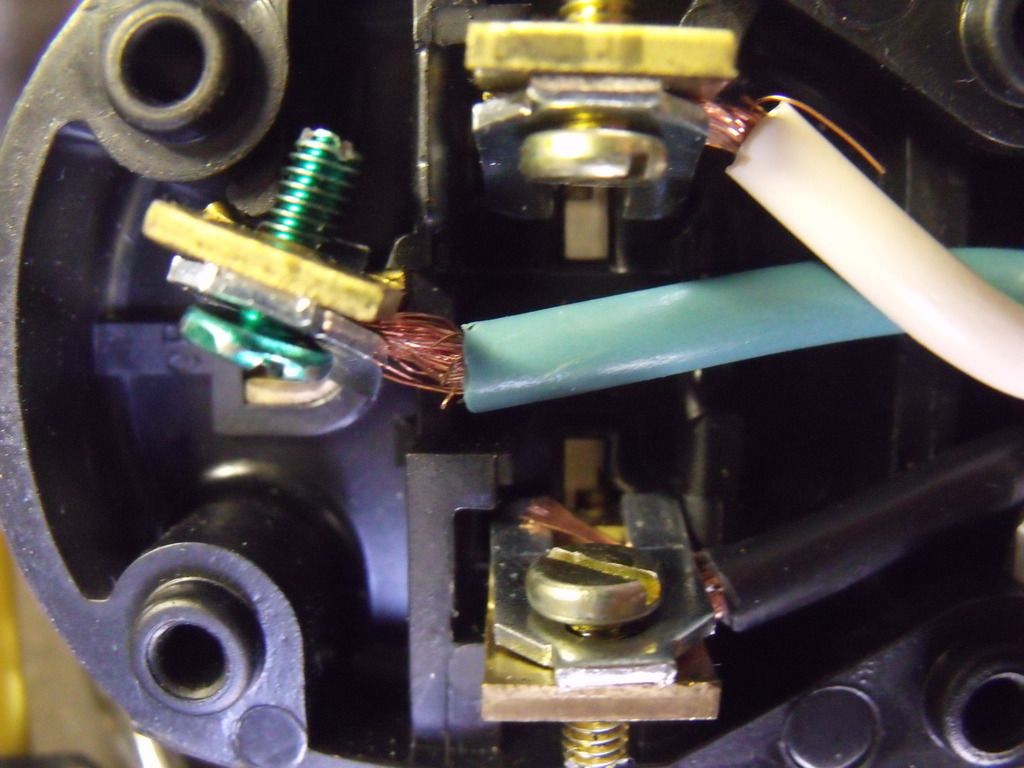

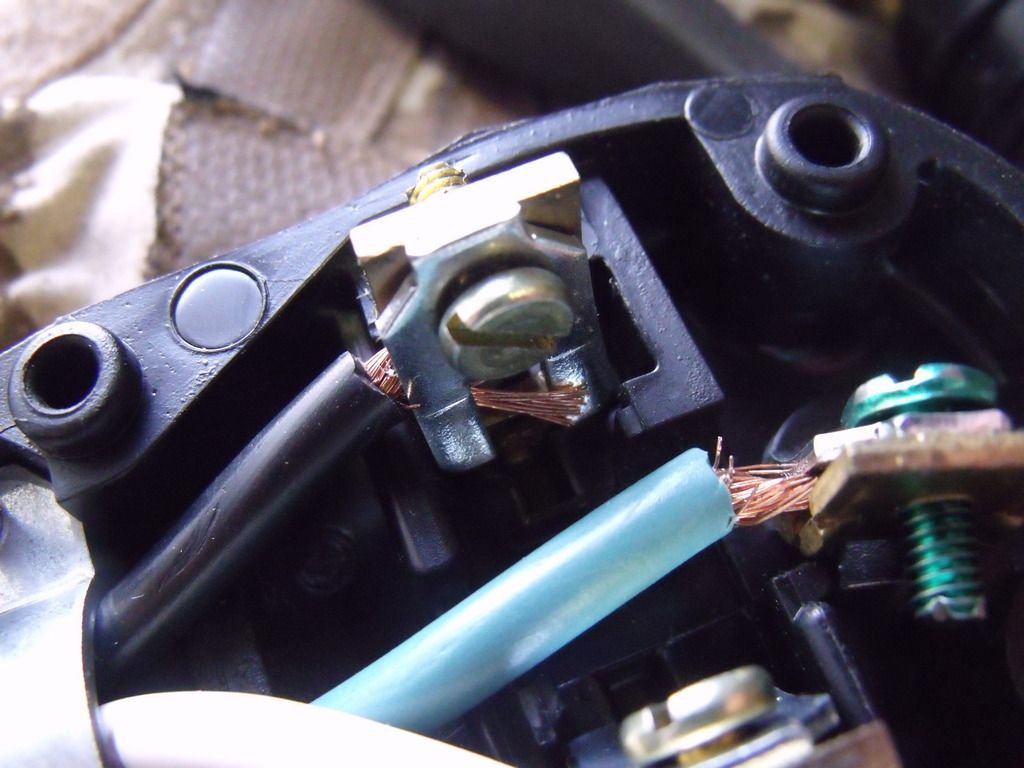

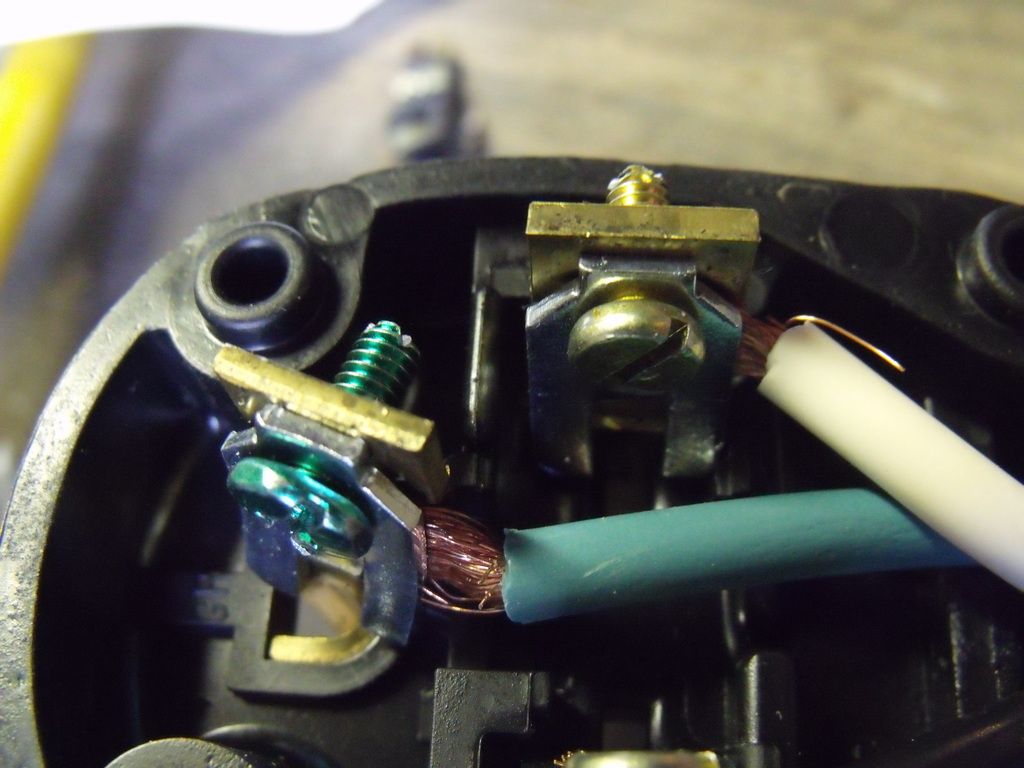

Melted L6-30

Melted L6-30 Opened by pliers as the plastic had melted together

Entire Adapter Cable

GFCI L6-30 Plug with Melted Plastic on it:

Immediately upon entering the garage, I smelled electrical burn and burned plastic. I saw smoke coming from the wire above my GFCI, went to my breaker box and made sure the power was off, the 30 amp breaker had flipped. I unplugged everything, however I had to wear gloves to unplug the NEMA L6-30 from my inline GFCI, as it was too hot to touch. I got my camera to document it and have drawn up a wiring diagram. I had to use pliers to pull apart the NEMA L6-30 as the plastic had completely melted.

Has this happened to anyone? Do you think I had a loose wire? A faulty NEMA L6-30? I am not an electrician, however from everything I have read states I have wired my setup correctly.

At the moment I am not really sure what I can do and if I can salvage the NEMA L6-30 plug on the GFCI as it has a bunch of melted plastic on it.

See Pics below:

Wiring Diagram

Melted L6-30

Melted L6-30 Opened by pliers as the plastic had melted together

Entire Adapter Cable

GFCI L6-30 Plug with Melted Plastic on it: