Hey everyone. I'll try to keep this post relatively short. I switched to kegging a year ago and 3 out of my last 4 batches have ended up tasting like butterscotch. 2 out of the 3 took a couple of weeks in the keg before the taste changed and my latest (an Imperial IPA) tasted off right after the keg was carbonated. All 3 beers tasted great prior to the butterscotch flavor.

I'm extremely careful with regard to cleaning and sanitizing but regardless, I took everything that touches the beer post-boil apart, cleaned everything thoroughly, boiled everything stainless for 20 minutes, replaced all plastics (including PET carboys), sanitized everything using StarSan and I'm ready to brew another batch.

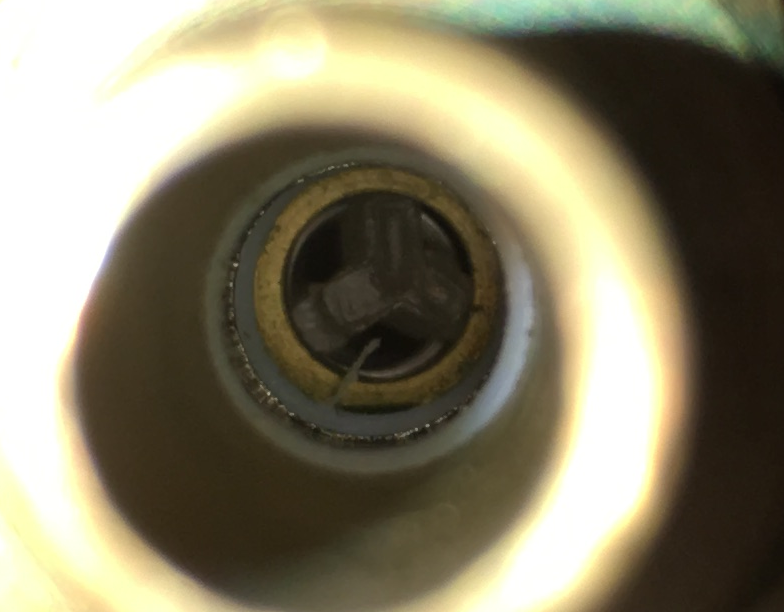

Upon reading tons of posts on infections, I decided to take apart my CO2 manifold just to check it out. The one beer that still tastes great is an American Wheat, which I had connected to Line 1 of the manifold. The other 3 beers had been connected to lines 2 and 3. Below are pictures of all 4 lines. Unless I'm seeing things, lines 2 and 3 look like something is growing in there. So, a couple of questions for those more knowledgeable than me.

1. Am I going crazy or do lines 2 and 3 look like they could be the source of my infections?

2. Assuming the answer to 1 is yes, what's the best way to clean and sanitize/sterilize the manifold? Should I replace all gas lines as well?

Thanks in advance!

I'm extremely careful with regard to cleaning and sanitizing but regardless, I took everything that touches the beer post-boil apart, cleaned everything thoroughly, boiled everything stainless for 20 minutes, replaced all plastics (including PET carboys), sanitized everything using StarSan and I'm ready to brew another batch.

Upon reading tons of posts on infections, I decided to take apart my CO2 manifold just to check it out. The one beer that still tastes great is an American Wheat, which I had connected to Line 1 of the manifold. The other 3 beers had been connected to lines 2 and 3. Below are pictures of all 4 lines. Unless I'm seeing things, lines 2 and 3 look like something is growing in there. So, a couple of questions for those more knowledgeable than me.

1. Am I going crazy or do lines 2 and 3 look like they could be the source of my infections?

2. Assuming the answer to 1 is yes, what's the best way to clean and sanitize/sterilize the manifold? Should I replace all gas lines as well?

Thanks in advance!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)