You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My home-brewed keg washer

- Thread starter McMullan

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It gives me ideas for the next time I have to redo mine.

Thx.

Thx.

That is a GREAT idea! You always have lots of cool tricks to share - Thanks!

visitor

Well-Known Member

Love the pin! Great washer, bet that makes cleaning more tolerable!

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

Nice to be able to use hot PBW.Love the pin! Great washer, bet that makes cleaning more tolerable!

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

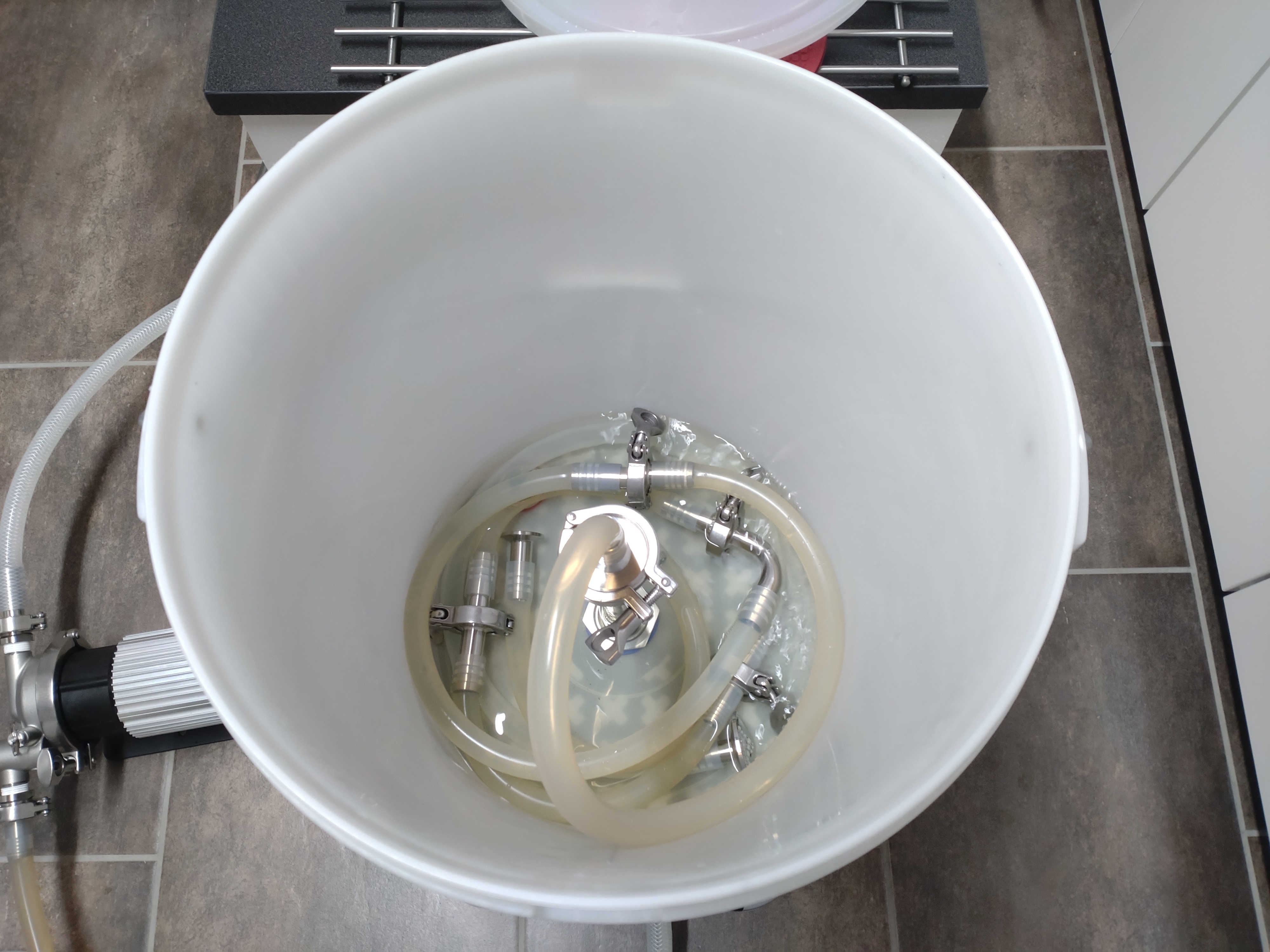

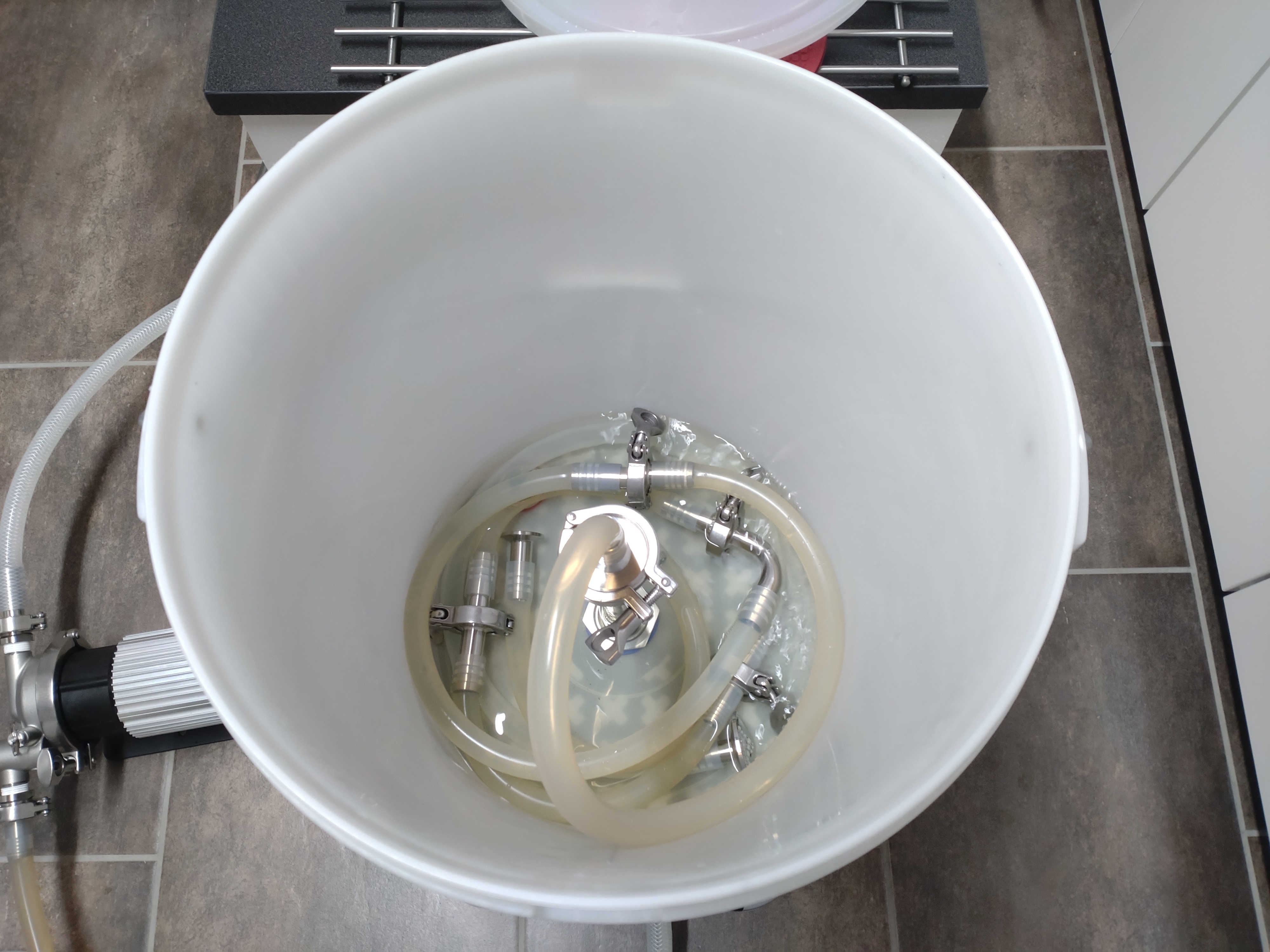

I was so inspired by McMullan's keg washer I hauled mine out to clean kegs. Mine sits in the brewery sink that has PBW and hot water. Quarter HP submersible pump installed in a five gallon pail with drilled holes.

Is that just a five gallon bucket and stepping stool you've repurposed? Genius!

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

The keg washer is getting so much use I'm now calling it 'brewery washer'. It's being used for my cask, kegs, FVs, yeast trough, silicone hose, fittings, anything that fits in there really. It uses 3L hot PBW, which can be reheated on the kitchen hob, if required. I use 4L when cleaning the CFC.

Last edited:

apache_brew

Well-Known Member

I love it. Definitely taking this design and running with it. Do you have some sort of screen on the return port so small parts don't get sucked into the pump?

apache_brew

Well-Known Member

What spray ball are you using? How happy are you with the upward spraying action from the Riptide pump?

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

It’s ‘micro’ spray ball. Got it off aliexpress a few years back. It works well with the RipTide. Very effective at distributing hot PBW solution. If I need to blast something like a dirty FV, I use a barbed fitting to create a powerful jet. Spray ball is better for cleaning stuff I throw into the washer (bucket) with the lid on.

visitor

Well-Known Member

Is that an adjustable pipe that you have from the base of the bucket to the sprayball?

I have my pipe/spray ball setup for corny keg washing and when I have a pin laid on the side like your photo above it's too tall which means I rig up some blocks to raise the pin up.

I have my pipe/spray ball setup for corny keg washing and when I have a pin laid on the side like your photo above it's too tall which means I rig up some blocks to raise the pin up.

agentbud

Well-Known Member

Does the dog help with cleaning?

Totally forgot about this thread....

I may copy that. I had a washer I made using a sterilite container and lots of PVC plumbing, but yours is a lot easier and simpler.

EDIT: @McMullan Did you just use triclamp (1.5"?) bulkheads for the inlet/outlet? I'm wondering if I can get away with 1/2" NPT bulkheads to save money.

I may copy that. I had a washer I made using a sterilite container and lots of PVC plumbing, but yours is a lot easier and simpler.

EDIT: @McMullan Did you just use triclamp (1.5"?) bulkheads for the inlet/outlet? I'm wondering if I can get away with 1/2" NPT bulkheads to save money.

Last edited:

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

She eats all the grains I drop. Helped herself to an open sack once. Crapped 'breakfast bars' for days. With a grimace on her face, poor thing.Does the dog help with cleaning?

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

The outlet is 1/2". The inlet is a bit unique, 1 1/2" double TC ferrule one end (underneath) and 1/2" female the other end (inside the large bulkhead locking nut).Totally forgot about this thread....

I may copy that. I had a washer I made using a sterilite container and lots of PVC plumbing, but yours is a lot easier and simpler.

EDIT: @McMullan Did you just use triclamp (1.5"?) bulkheads for the inlet/outlet? I'm wondering if I can get away with 1/2" NPT bulkheads to save money.

My dogs love spent grain; has the same effect.She eats all the grains I drop. Helped herself to an open sack once. Crapped 'breakfast bars' for days. With a grimace on her face, poor thing.

The outlet is 1/2". The inlet is a bit unique, 1 1/2" double TC ferrule one end (underneath) and 1/2" female the other end (inside the large bulkhead locking nut).

Was there a reason why you went with the 1 1/2" double TC ferrule or could you just stay with female 1/2"?

Similar threads

- Replies

- 10

- Views

- 891

- Replies

- 2

- Views

- 333

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)