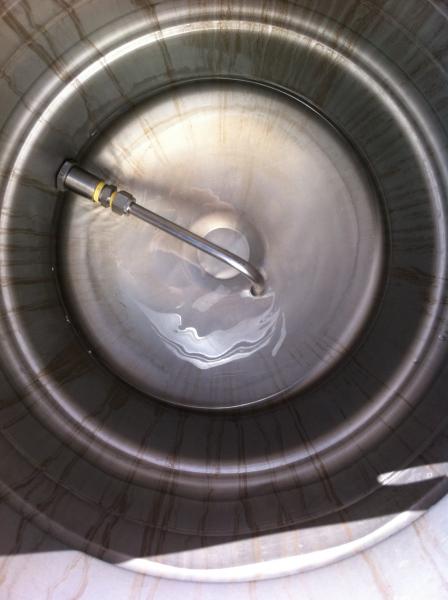

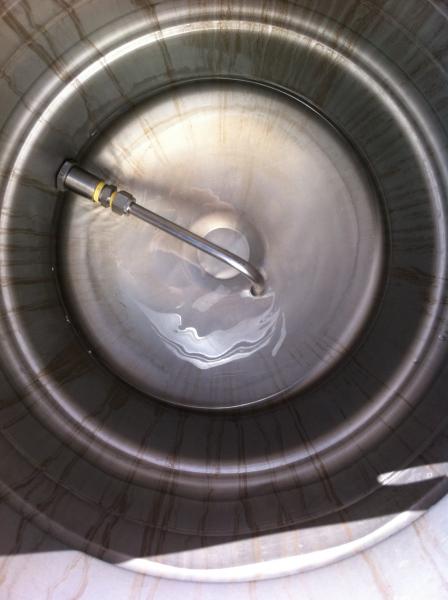

I bought all the parts from Bargain fittings. I followed the directions on their website to a T, but it didn't turn out right. Don't know if it's because it's one of those fatty kegs or what, but I DO know that there is over a gallon of water left over in the bottom that won't drain. I'm sorry the pics are hard to see.

Can I bend the dip tube some how? I already tightened the compression fitting so I dont know about changing it to a side pickup. :/

Any help would be greatly appreciated! Oh, the dip tube is about an inch from the bottom. I has a mean angle to it!

Can I bend the dip tube some how? I already tightened the compression fitting so I dont know about changing it to a side pickup. :/

Any help would be greatly appreciated! Oh, the dip tube is about an inch from the bottom. I has a mean angle to it!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/417FujUfrWL._SL500_.jpg)