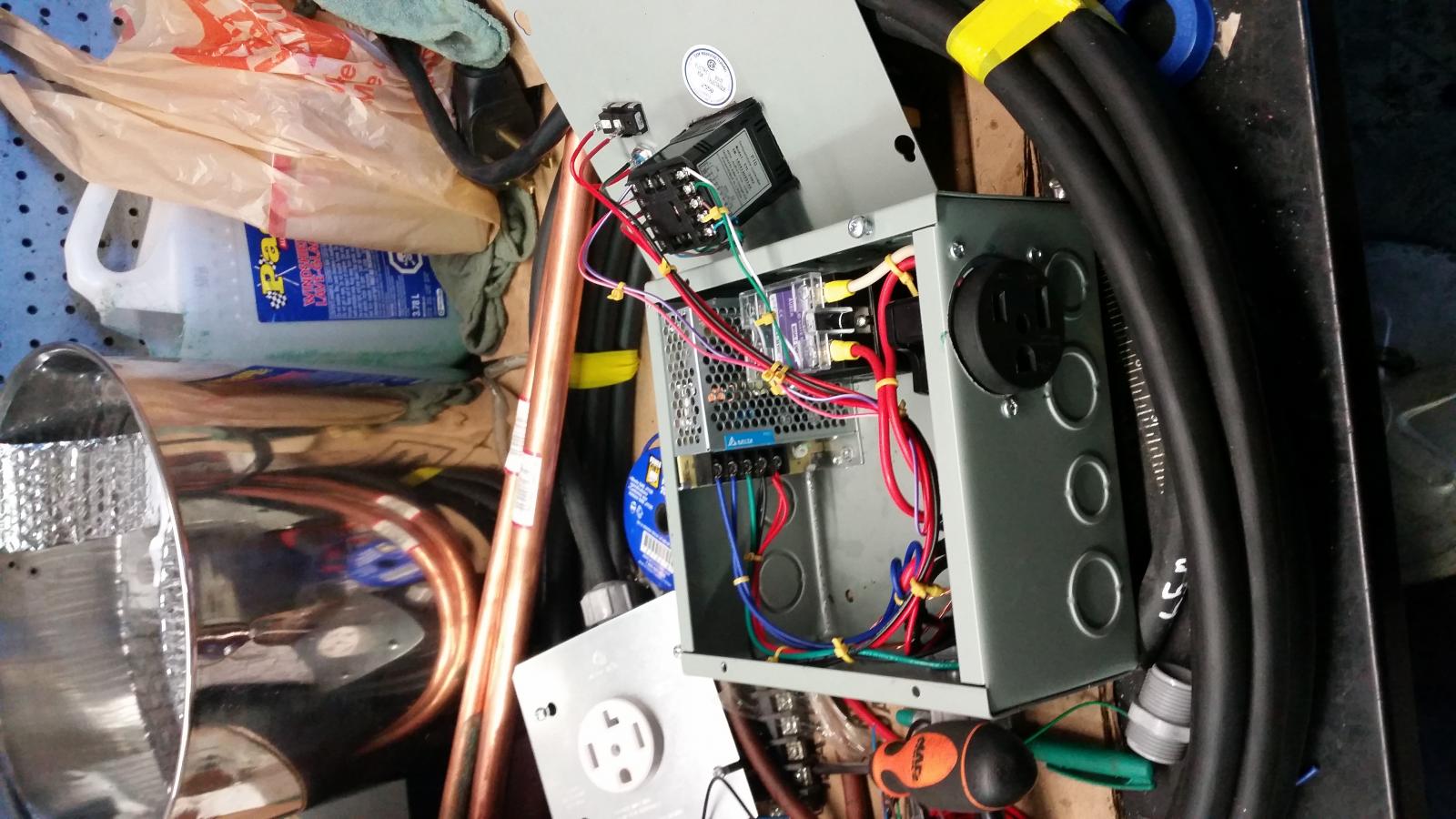

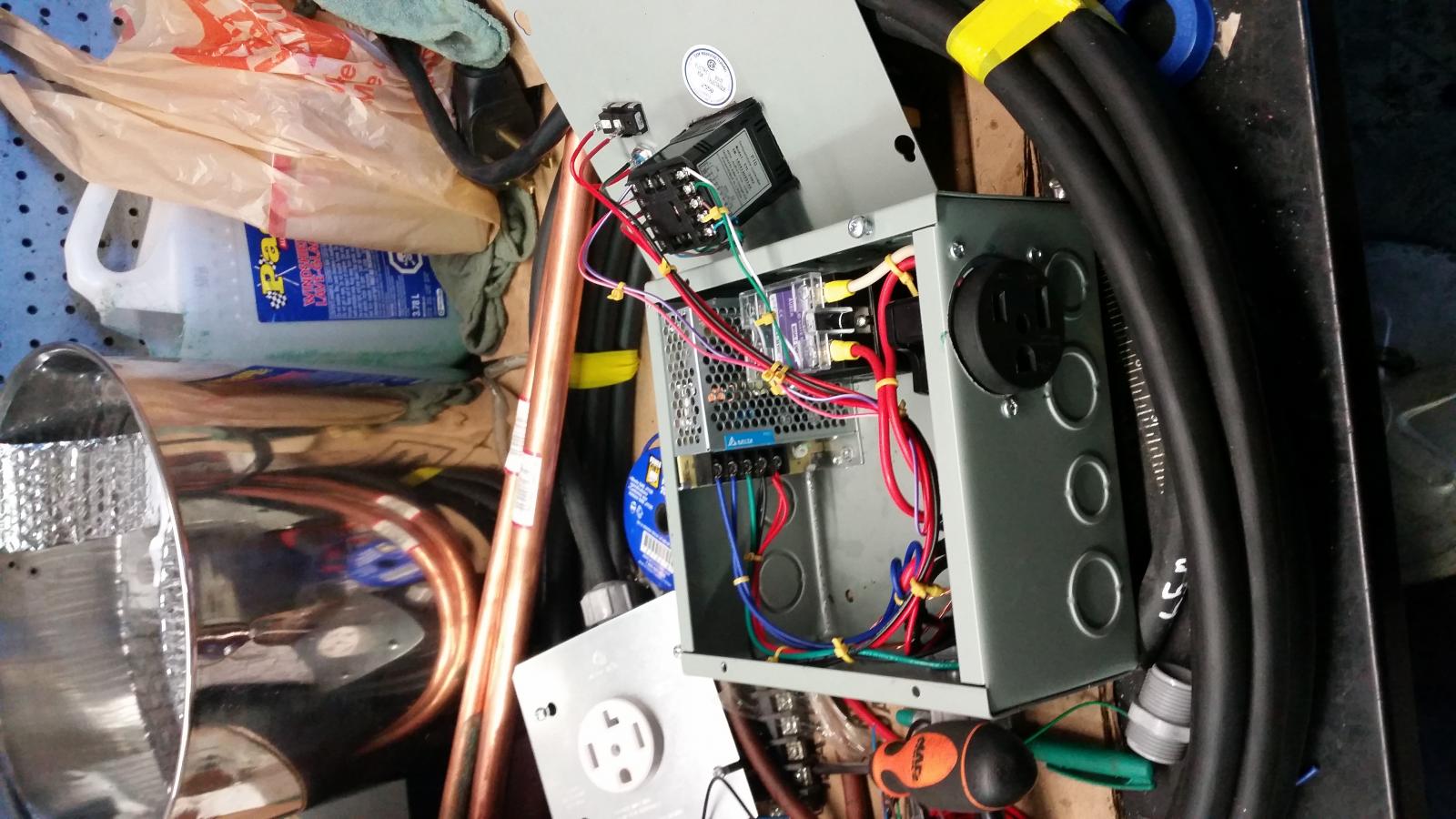

I have built a keg kettle with a 5500W heating element driven by an auburn PID controller and a DIY box. I have modified a 5 gallon stock pot using pizza screens and a grease splatter screen as a grain basket with a copper pipe running down the middle with holes drilled in it to supply water to the middle of the grain bed using a 12v water pump I have also used a piece of threaded stainless steel rod to hold the screens in place and act as a centering piece for the pipe as well as being able to push a pot lid down by means of screwing a nut down to squeeze the grain. I have included pics of my kettle and controller but not of the grain basket as I'm not fully finished and I'm also building a 2' high wood platform to put the kettle on and mount the control box to so I can store everything elsewhere from my kitchen.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)