Introducing the Maven Brewing System.

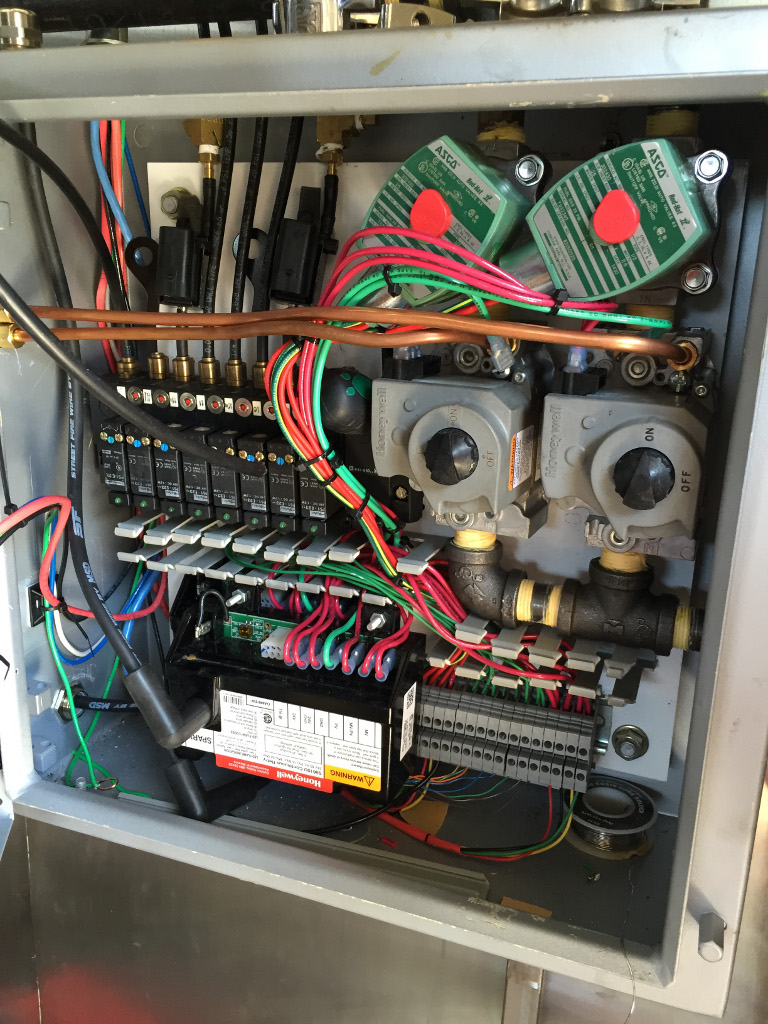

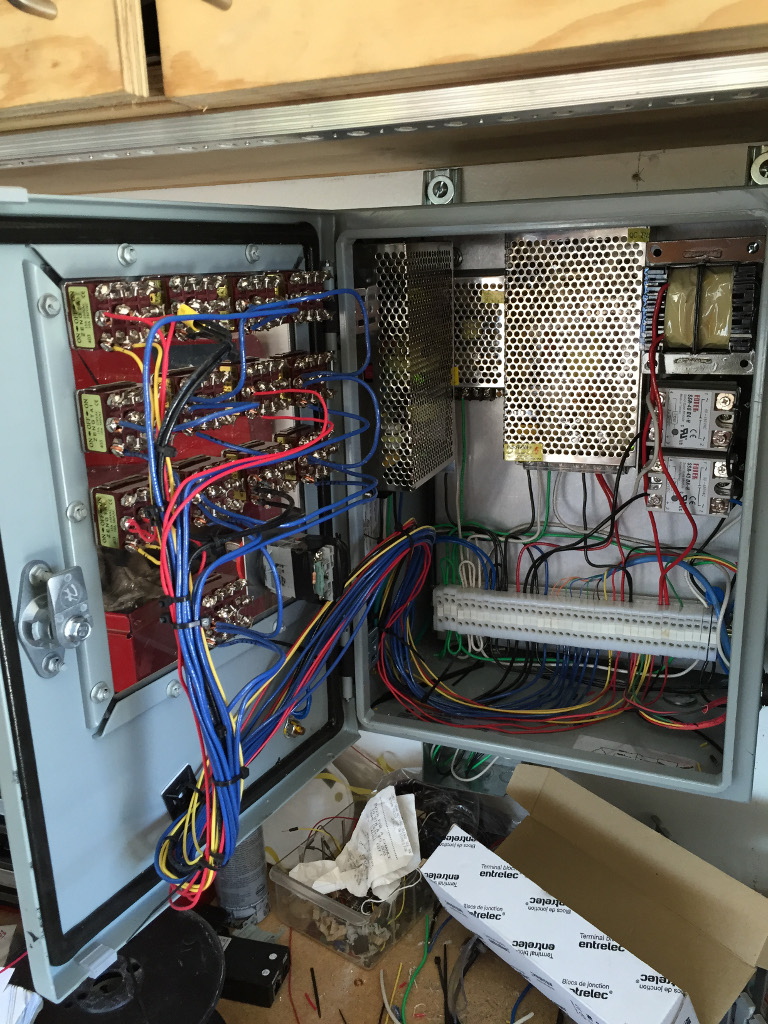

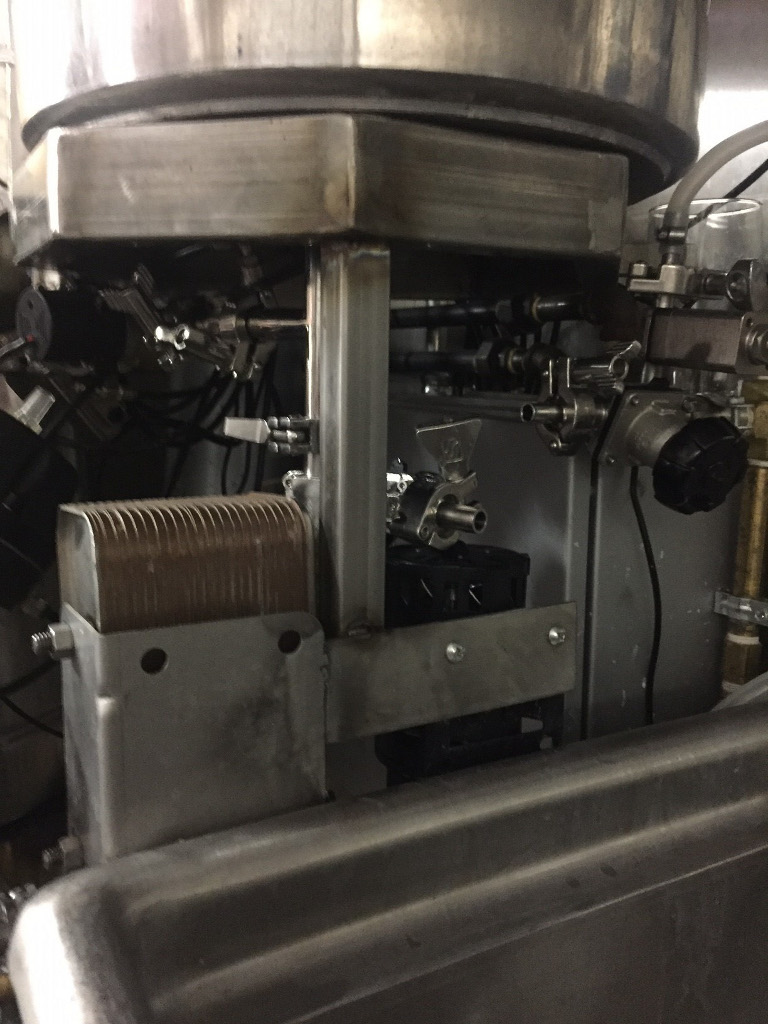

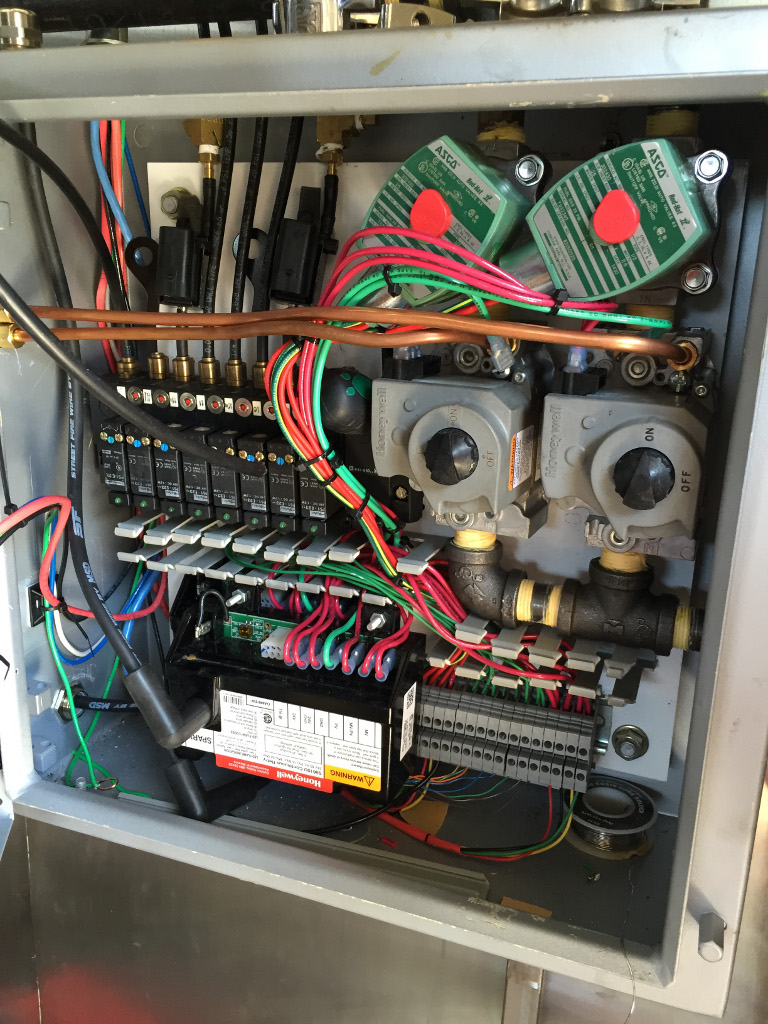

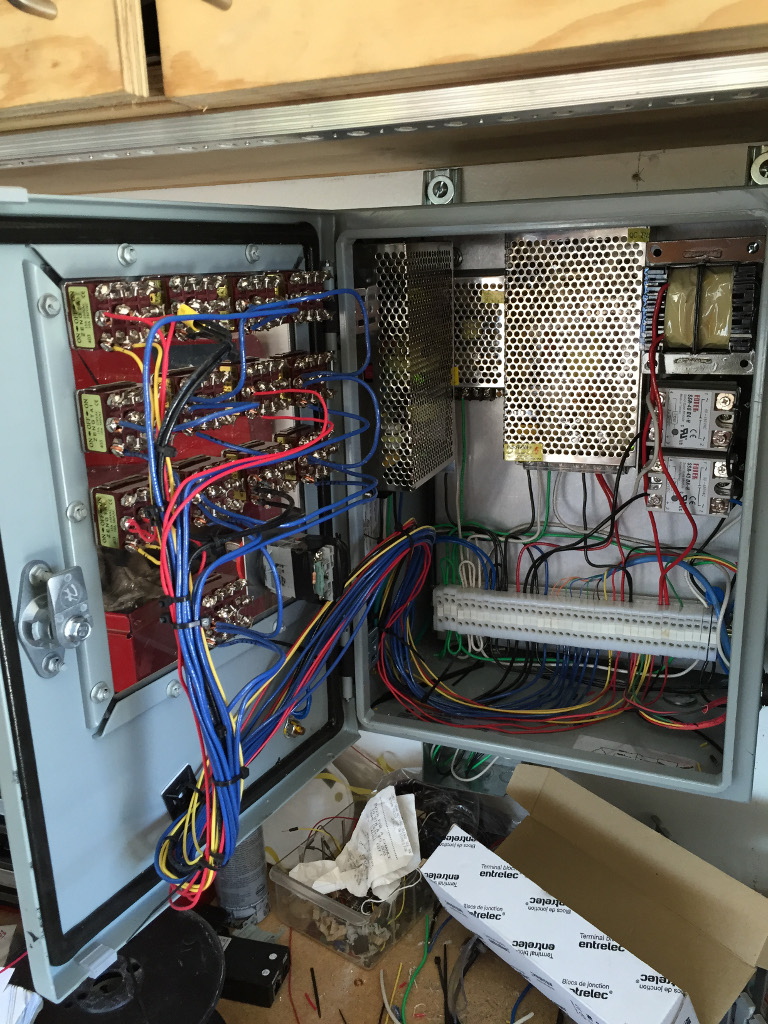

It took roughly 1 year to create, starting with bringing in natural gas pipe into the garage (and oversizing my feed out of the meter), bringing hot/cold water in, and then fabricating all that you see. The controls for now are toggle switches, which operate the burners, pumps and pneumatic diaphragm valves. Eventually some of these operations will have more automation, but for right now, manual is quite alright.

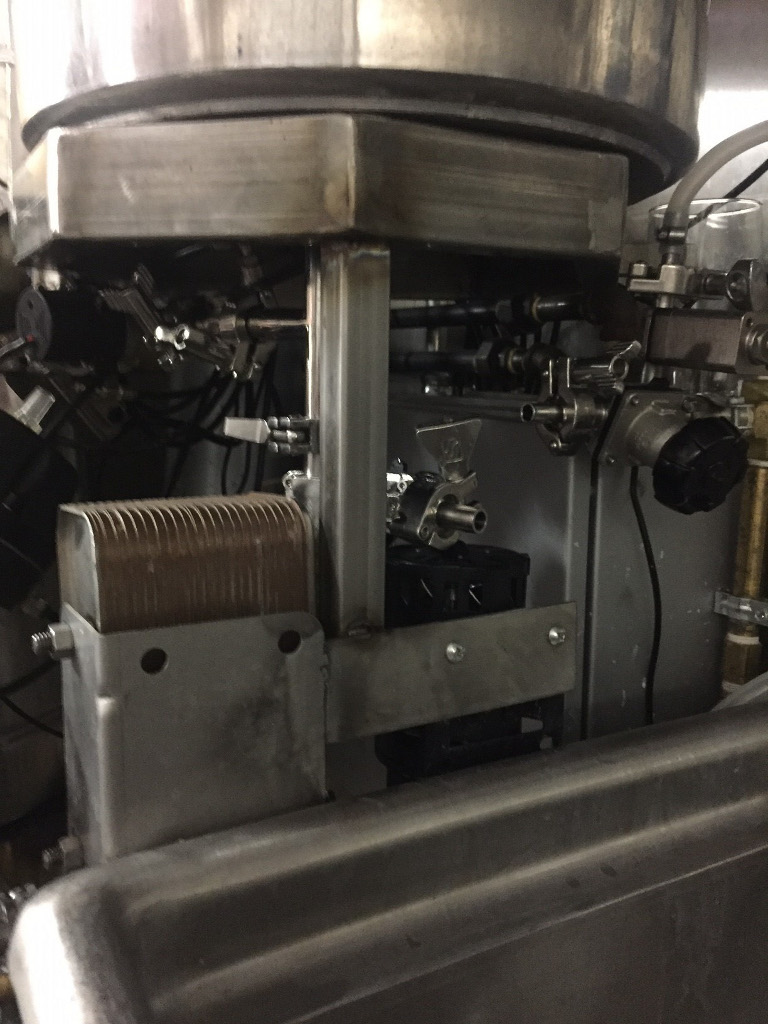

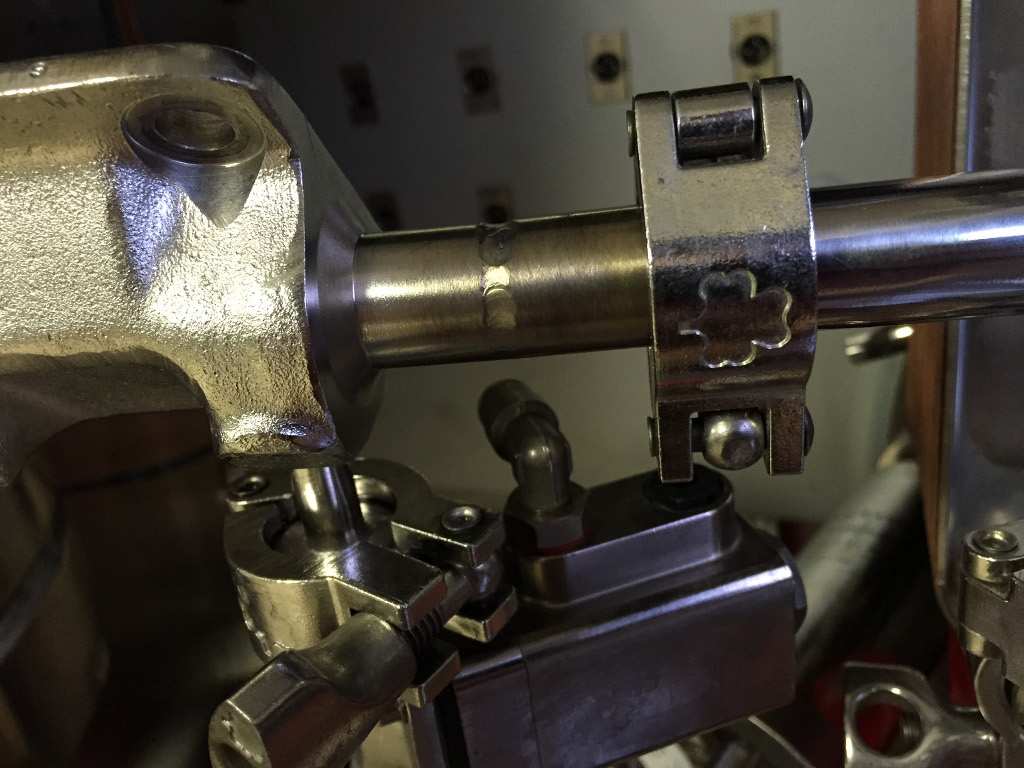

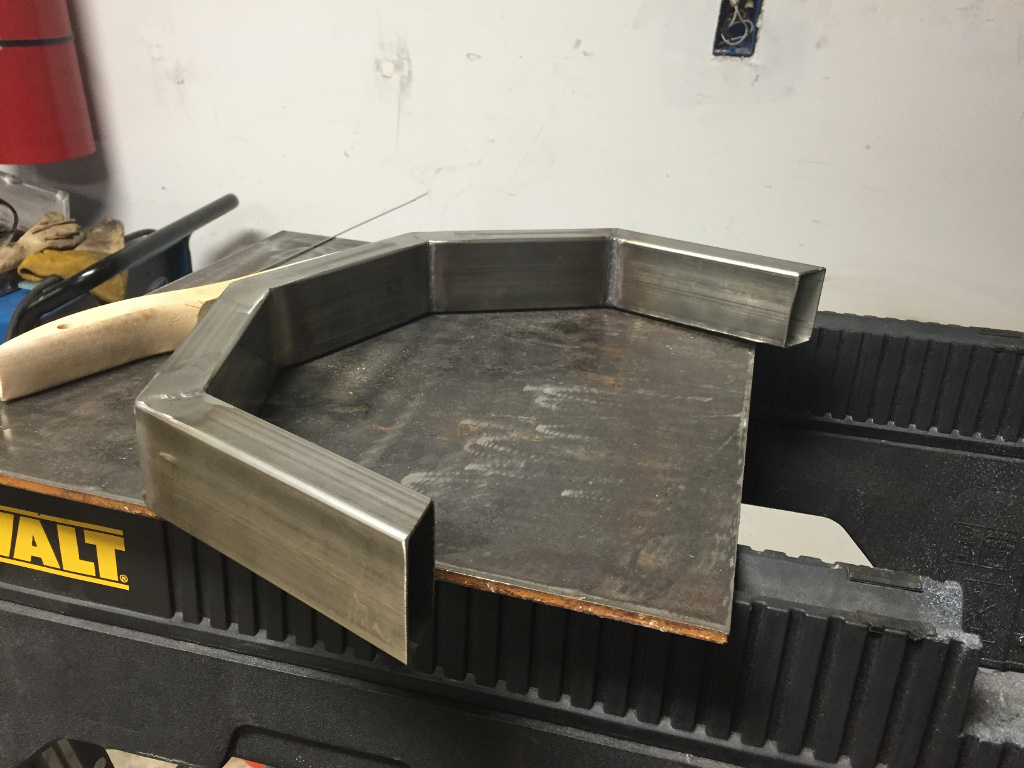

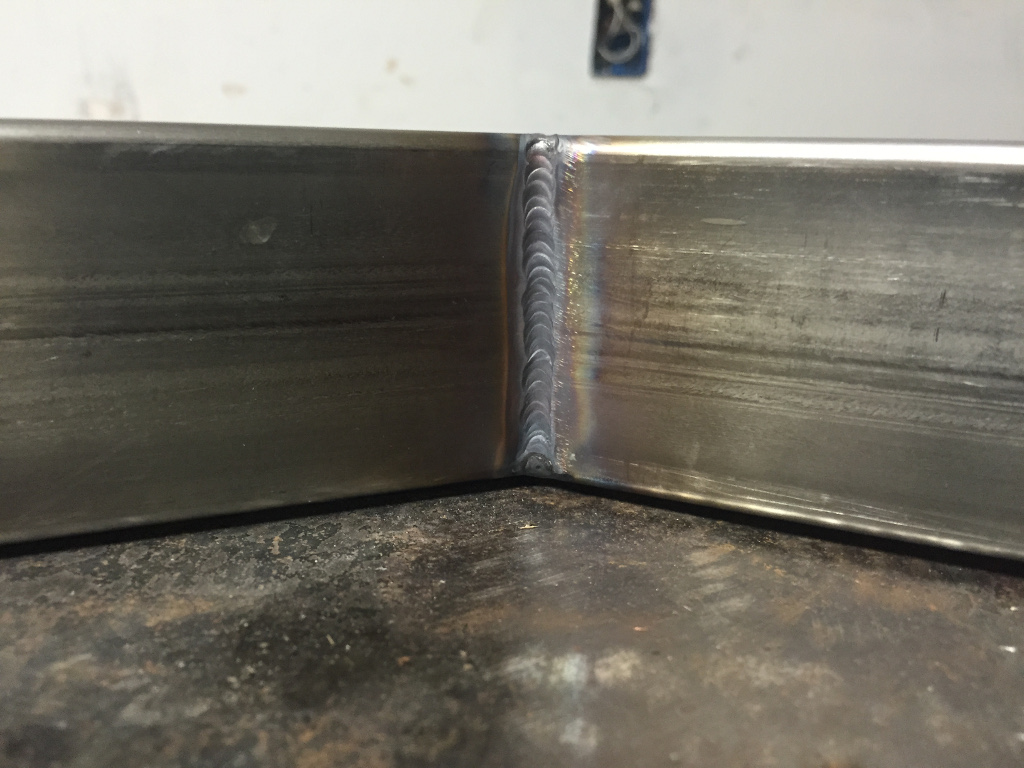

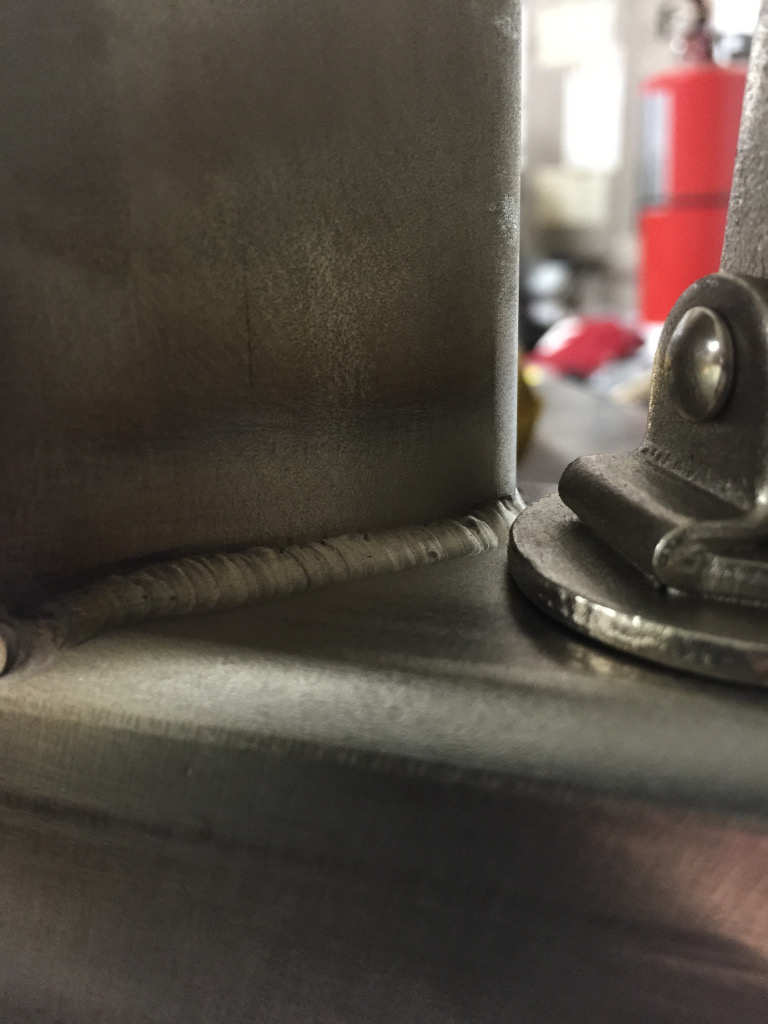

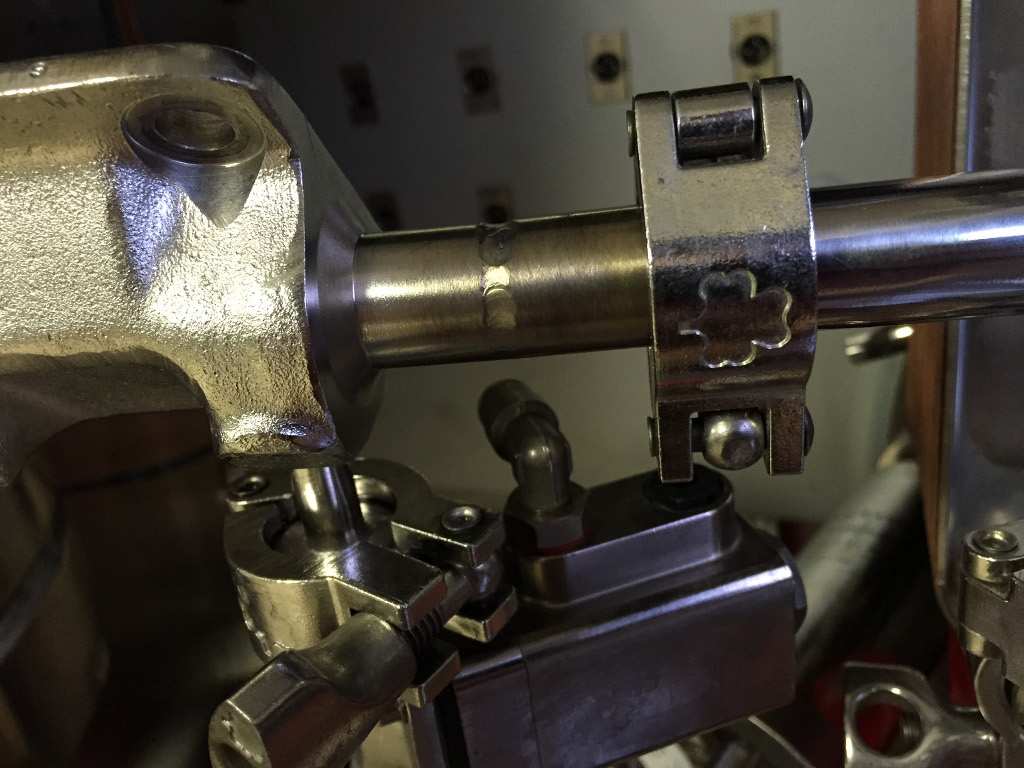

It is a custom stainless 3 tier stand. Batch size is 10 gallons. 8 gallon HLT (building a 16gal version currently), 16 gallon Mash Tun and Brew Kettle. Banjo burners for the HLT and BK. HERMS recirculation in the HLT controls mash temp. It also has a chiller loop using a Chill-Wizard and a tangential inlet into the brew kettle for whirlpool action. Most of the valves are all Gemu pneumatic diaphragm valves that I've been acquiring over time (expensive when new, just have to find the right deals on eBay). I have a few manual diaphragm valves as well for chill water flow control and mash tun test port. The top half stainless tubing is all 1/2" OD, the chiller loop has some 1" and 3/4". All of which I hand TIG welded (wish I had access to an orbital tig...). One chugger pump for HLT to MT, and another for the chiller loop. I also have a stainless TopsFlo pump for the HERMS/wort transfer.

I also installed a 3'x3' Type II vapor hood with a 12" duct out the roof with a 1200cfm fan to remove CO, vapor, and heat from the system. Make up air is by means of cracking my garage door 6" to prevent a depressurization condition.

Anyway, I'm 6 batches in, and it's working extremely well. If you have any questions or comments, don't hesitate to ask!

Cheers!

Matt Kosonen

It took roughly 1 year to create, starting with bringing in natural gas pipe into the garage (and oversizing my feed out of the meter), bringing hot/cold water in, and then fabricating all that you see. The controls for now are toggle switches, which operate the burners, pumps and pneumatic diaphragm valves. Eventually some of these operations will have more automation, but for right now, manual is quite alright.

It is a custom stainless 3 tier stand. Batch size is 10 gallons. 8 gallon HLT (building a 16gal version currently), 16 gallon Mash Tun and Brew Kettle. Banjo burners for the HLT and BK. HERMS recirculation in the HLT controls mash temp. It also has a chiller loop using a Chill-Wizard and a tangential inlet into the brew kettle for whirlpool action. Most of the valves are all Gemu pneumatic diaphragm valves that I've been acquiring over time (expensive when new, just have to find the right deals on eBay). I have a few manual diaphragm valves as well for chill water flow control and mash tun test port. The top half stainless tubing is all 1/2" OD, the chiller loop has some 1" and 3/4". All of which I hand TIG welded (wish I had access to an orbital tig...). One chugger pump for HLT to MT, and another for the chiller loop. I also have a stainless TopsFlo pump for the HERMS/wort transfer.

I also installed a 3'x3' Type II vapor hood with a 12" duct out the roof with a 1200cfm fan to remove CO, vapor, and heat from the system. Make up air is by means of cracking my garage door 6" to prevent a depressurization condition.

Anyway, I'm 6 batches in, and it's working extremely well. If you have any questions or comments, don't hesitate to ask!

Cheers!

Matt Kosonen