I'm about two months into this hobby and have been enjoying it thus far. I started with a German Ale (drinkable), then a Celis White clone (carbonating still) and just this past Sunday brewed a Watermelon Ale. The gravity I took just prior to pitching yeast was around 1.056 which seems a good amount higher than the 1.040 expected. this particular Ale ferments between 60-65F and the perfect spot in my house is my bedroom in a corner which hovers between 60.5 and 62. I have it in a brew pale with a gasket and rubber stopped and 3 piece air lock. It started bubbling slow by Sunday night and has been bubbling actively since then.

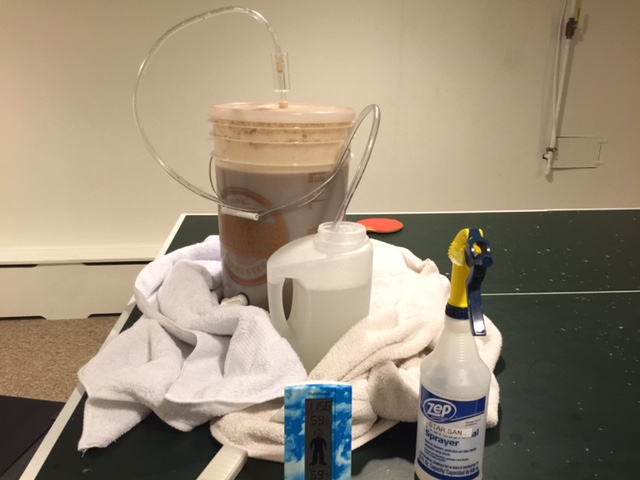

That leads me to early this morning - 4AM to be exact. The air lock must have started to clog and it woke my wife an I up by hissing at us. I assured her it's no big deal and took out the air lock cleaned it then rinsed with Star San and put it back in. About 10 minutes later I checked it again (couldn't go right back to sleep) and it was filling back up with crud. Luckily (because I've been religiously studying this forum for the past 2 months) I knew how to do a "blow off tube". I set that up by 4:15 and attempted to go back to sleep. About 15 minutes later a loud "Glub, glub glub" make us jump up again. It was just a lot of air coming through. That continued (and still does).

The biggest surprise was when I got out of the shower I saw that the bucket top had blown off and the tube wasn't even clogged in any way. It was still on top of the bucket but the red gasket was in the beer and the cover was teetering on top. I took the top off carefully, cleaned everything and sanitized then put it all back together. Then I took the whole set up to my 59.5 degree basement. The wife is happy now and I just hope it continues in that just under 60 degree environment.

If any one has guidance, ideas or knows if I did anything wrong please let me know.

That leads me to early this morning - 4AM to be exact. The air lock must have started to clog and it woke my wife an I up by hissing at us. I assured her it's no big deal and took out the air lock cleaned it then rinsed with Star San and put it back in. About 10 minutes later I checked it again (couldn't go right back to sleep) and it was filling back up with crud. Luckily (because I've been religiously studying this forum for the past 2 months) I knew how to do a "blow off tube". I set that up by 4:15 and attempted to go back to sleep. About 15 minutes later a loud "Glub, glub glub" make us jump up again. It was just a lot of air coming through. That continued (and still does).

The biggest surprise was when I got out of the shower I saw that the bucket top had blown off and the tube wasn't even clogged in any way. It was still on top of the bucket but the red gasket was in the beer and the cover was teetering on top. I took the top off carefully, cleaned everything and sanitized then put it all back together. Then I took the whole set up to my 59.5 degree basement. The wife is happy now and I just hope it continues in that just under 60 degree environment.

If any one has guidance, ideas or knows if I did anything wrong please let me know.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)