SpaceCoastBrew

Well-Known Member

I recently acquired a MM2-2.0 and a bodine gear motor for my direct drive milling station. I'm trying to keep this as simple and safe as possible. The gear motor is reversible so I was thinking of using a keyed fwd-off-rev switch like this one: GCX1470-22 Products and a mushroom style E-stop button.

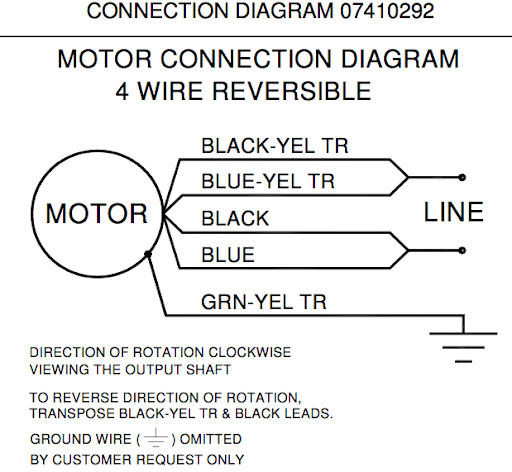

Is there any reason why this wouldn't work? And what would be the best way to wire this? Here's the motor wiring sheet:

Is there any reason why this wouldn't work? And what would be the best way to wire this? Here's the motor wiring sheet:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)