tjpfeister

Well-Known Member

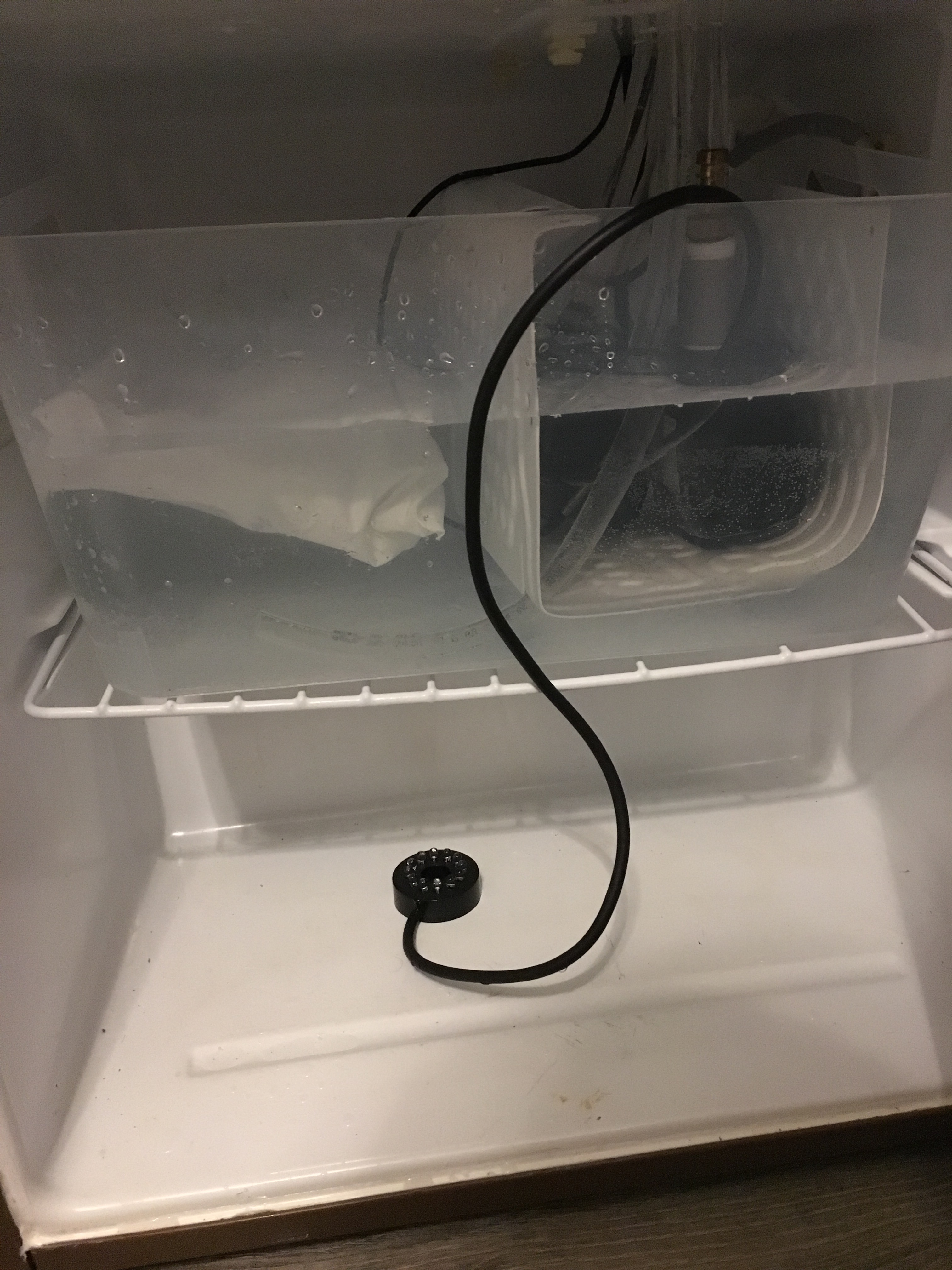

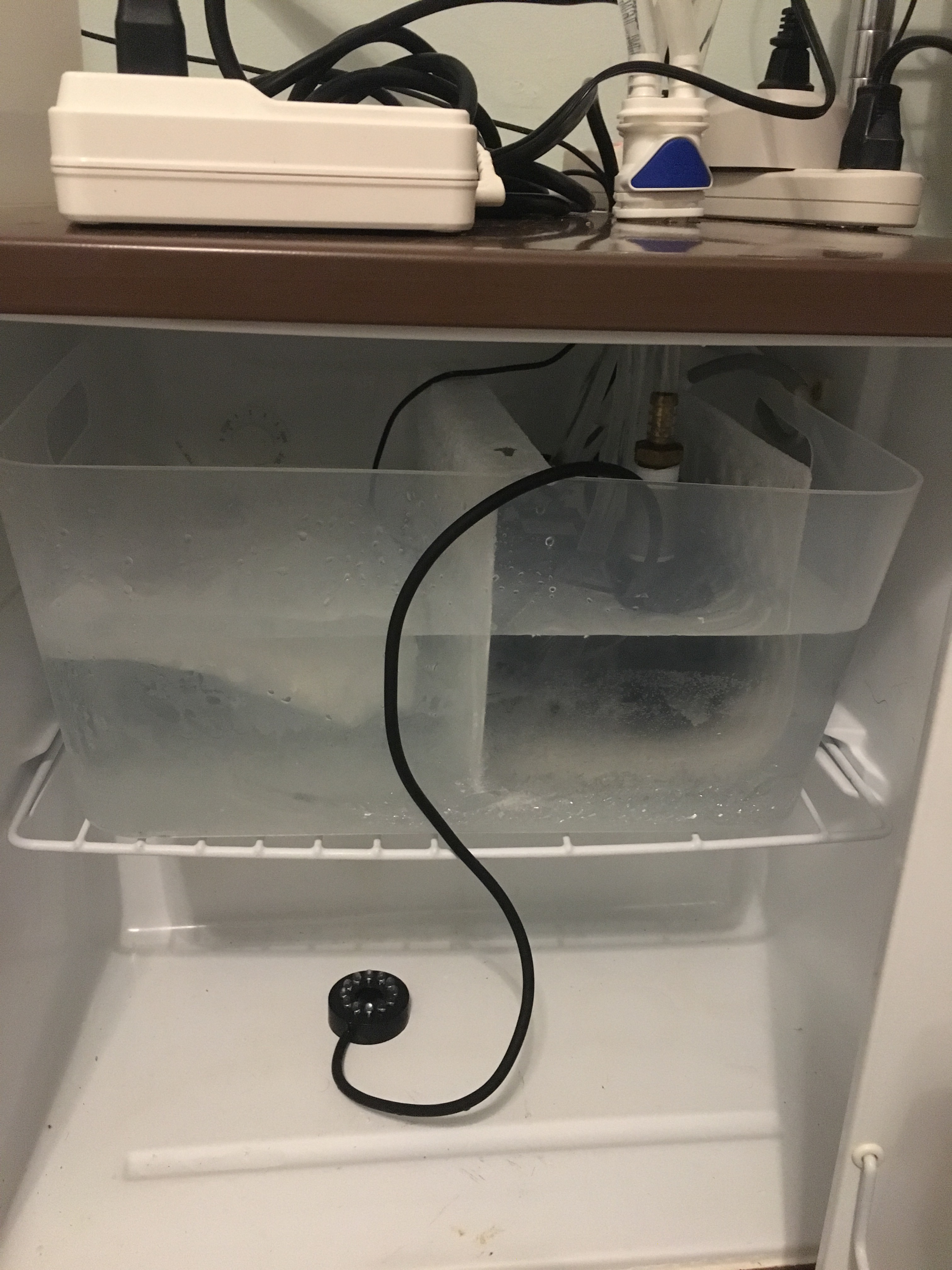

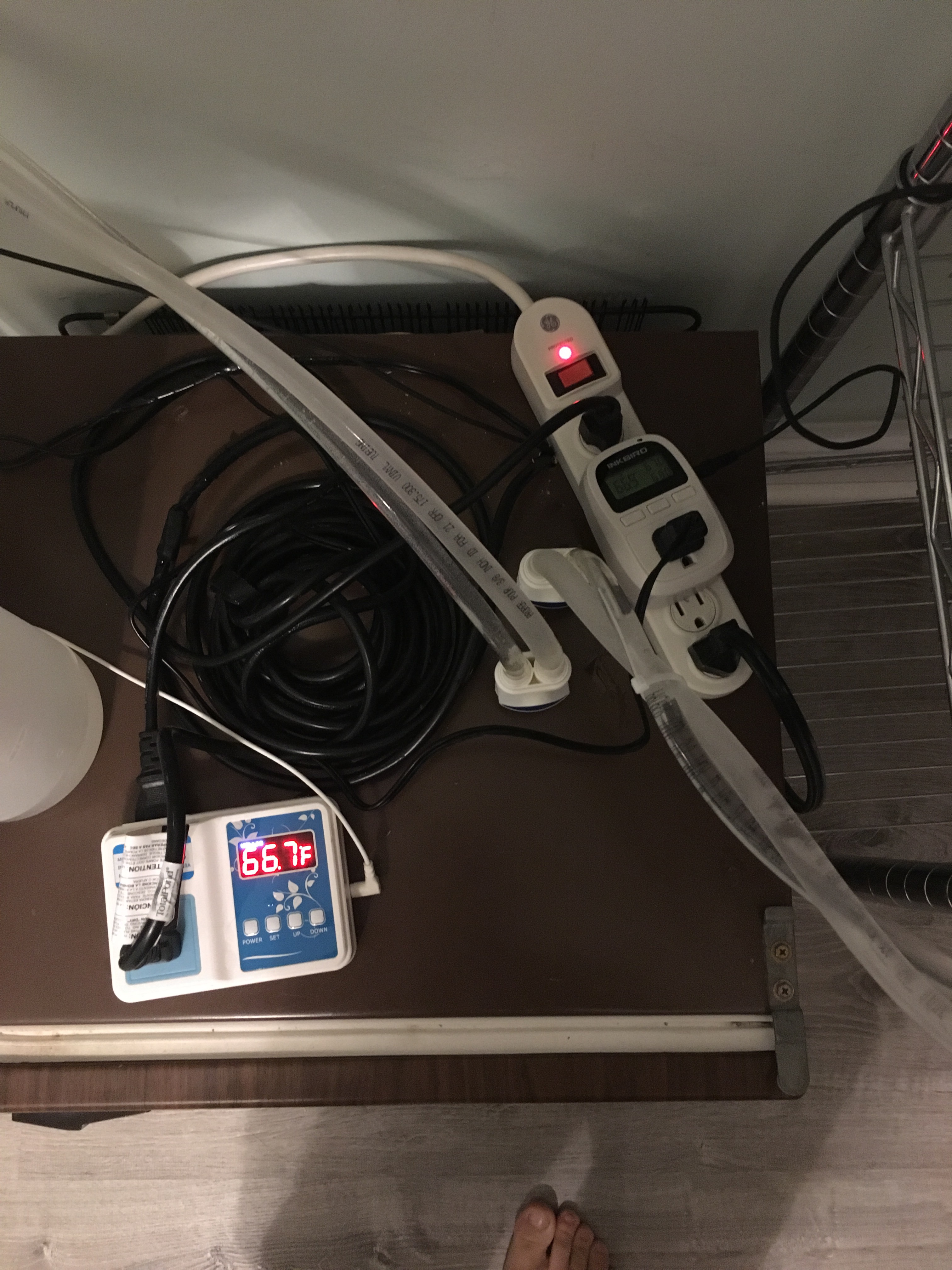

In case anyone is following- the first two hours of run time demonstrated a problem. The condenser simply wasnt built to dissipate THAT much thermal energy. The fridge smelled hot and the compressor kept tripping the thermal breaker. After 2 hours it had stalled at 54F when starting at 62F. Air movement is needed.

Tonight I purchased a small fan and positioned it to blow over the condenser and compressor... The results are much better, the first hour dropped 62F down to 47F and the unit is not getting hot. By my math 15Fx10galx8lbs= 1200btu

Thats not massive, but it is a respectable number. Ill keep it running and post back the results as I feel significance warrants.

Suffice it to say, without a condenser fan this project will not work.

Tonight I purchased a small fan and positioned it to blow over the condenser and compressor... The results are much better, the first hour dropped 62F down to 47F and the unit is not getting hot. By my math 15Fx10galx8lbs= 1200btu

Thats not massive, but it is a respectable number. Ill keep it running and post back the results as I feel significance warrants.

Suffice it to say, without a condenser fan this project will not work.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)