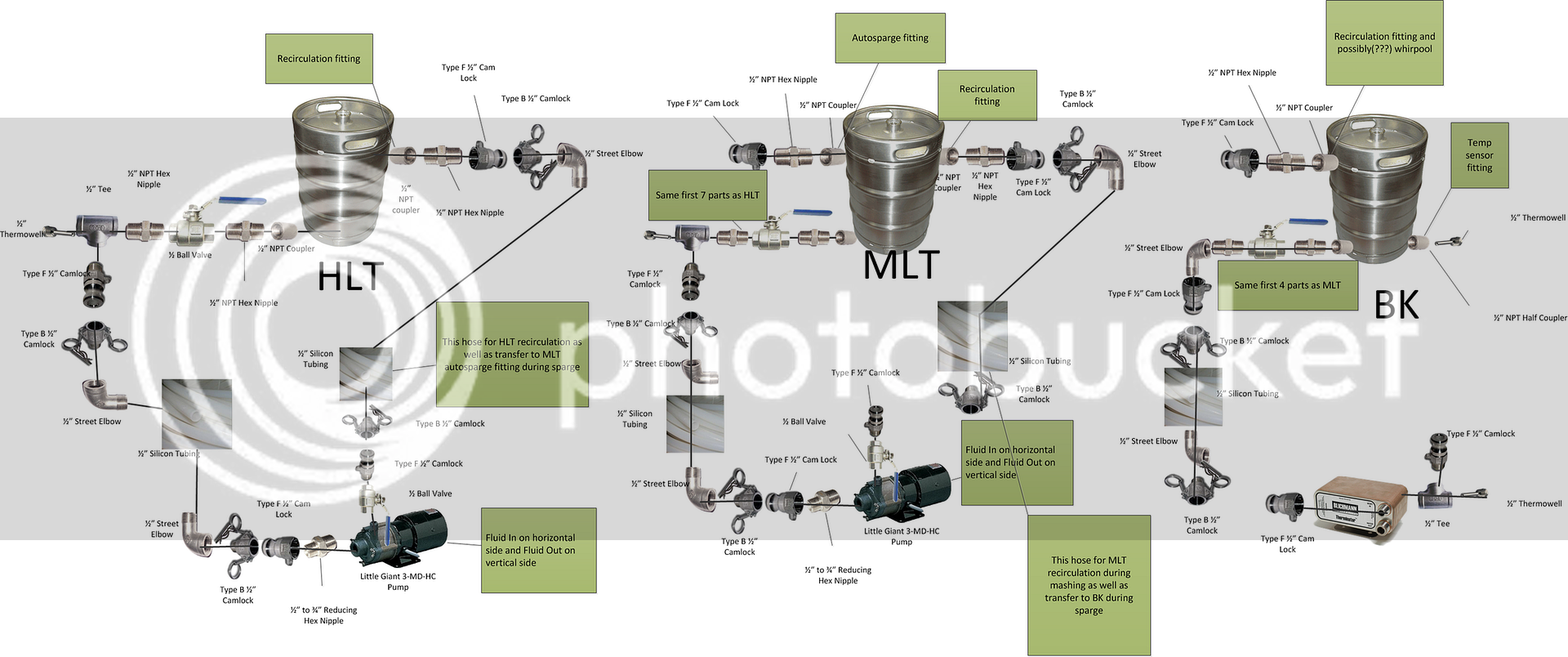

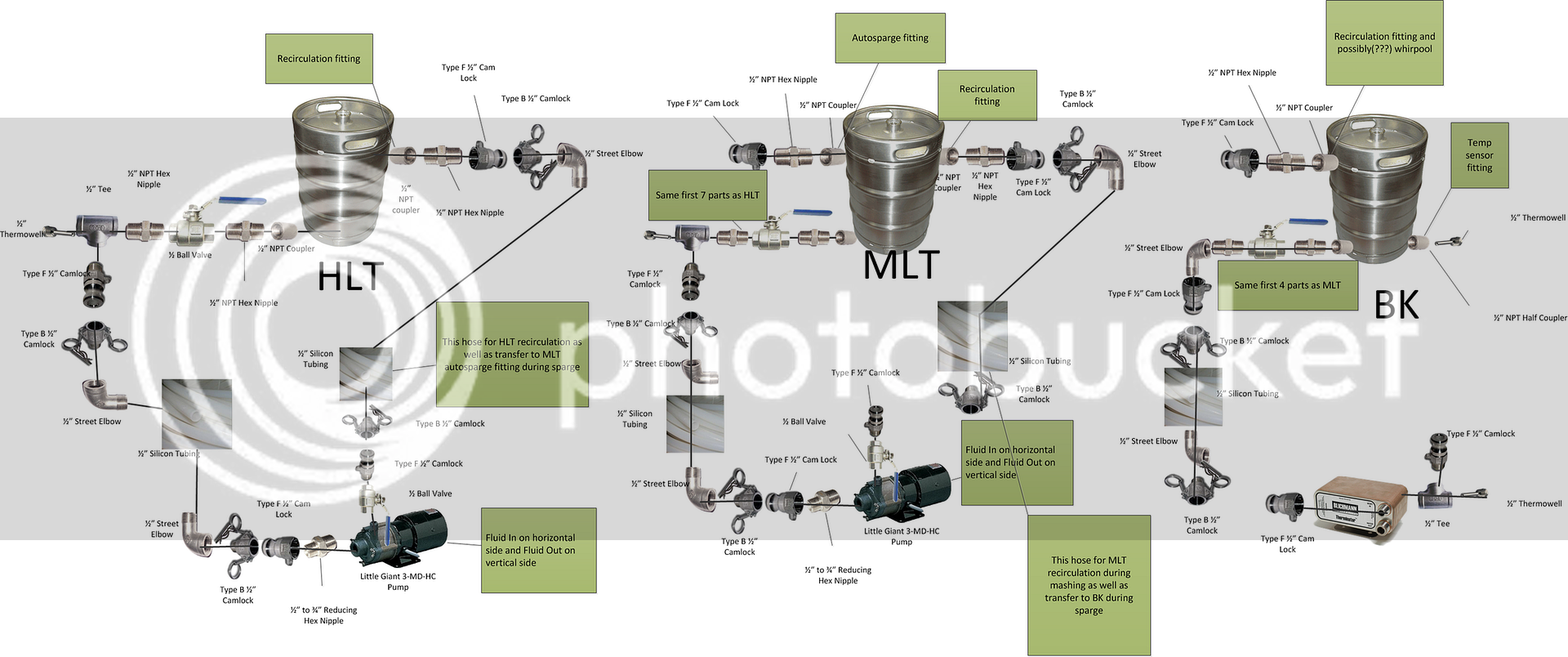

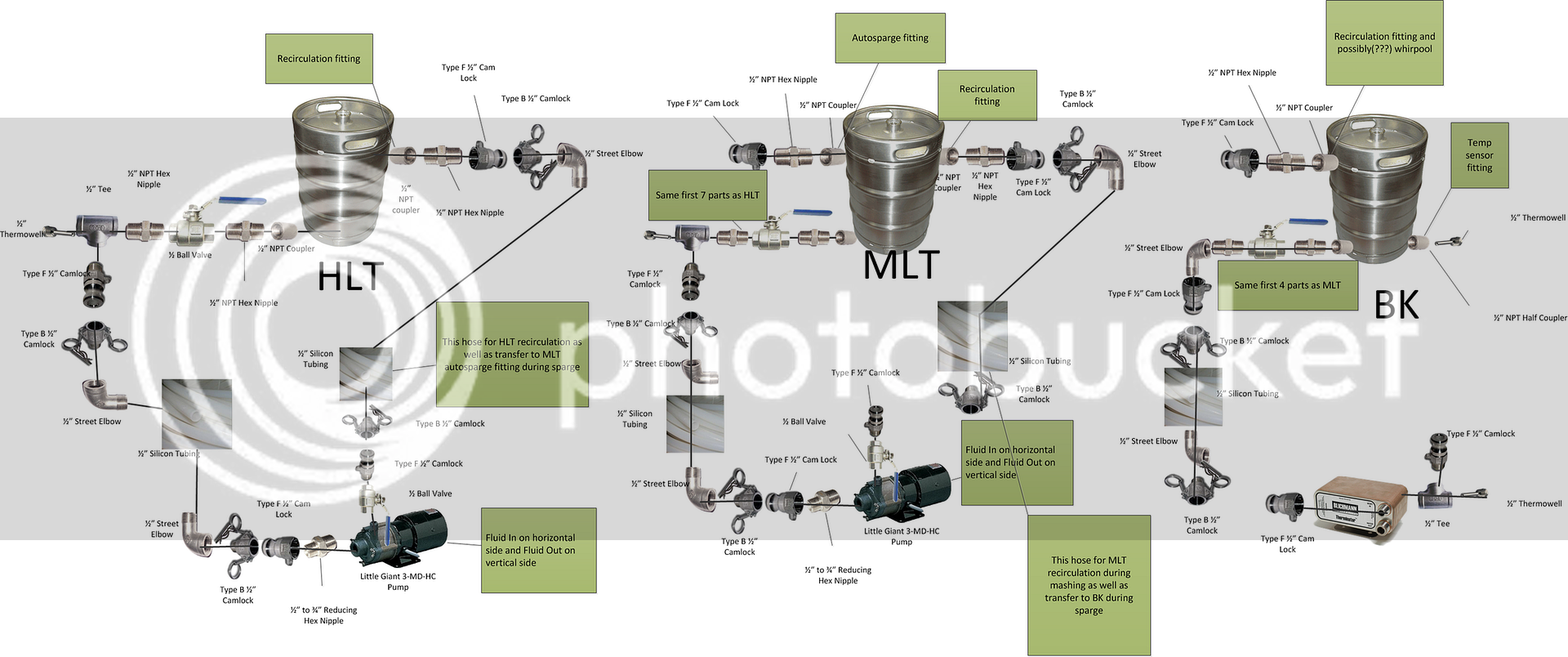

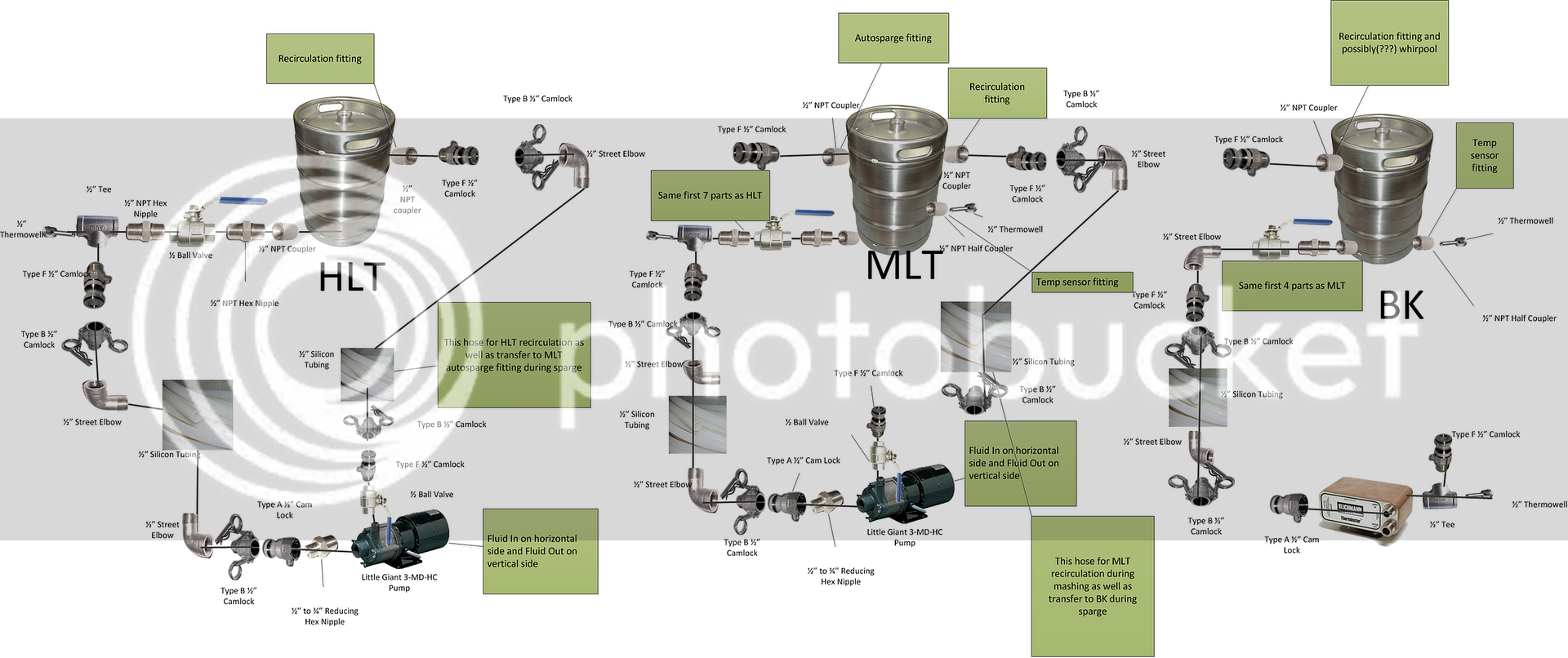

All of your male camlocks are labeled type F, even though it looks like many of them are actually type A. You could eliminate a lot of the hex nipples if you switched a bunch of the type A camlocks to F, which is maybe why they're mislabeled? Same goes for the one at the BK drain valve, just flip the street 90 and use a type F instead of A. Or are you adding the nipples to get the fittings further away from the vessels, which might be needed with the 90's on the hose side of the camlocks? I've not considered putting the 90 on the hose side, and I'll be curious to know how well that works out. Depending on how high your recirculation fittings are mounted some of them may need valves added.

As for the comment about 1/2" ID fittings actually being smaller, that applies to the barbed fittings, which I don't see any of in your diagram. You should have a full 1/2" of flow through the whole system the way it's drawn.