I ordered and received 2 regular SS and 2 Flow Control Intertap faucets from the Aliexpress seller Brewsmaster. I bought these to replace Perlick 525PC models that had started leaking after a few years (also, the chrome had eroded away on the inside of the faucets exposing the brass). After finding ~4 gallons of my homebrew on the floor one morning I'll never trust the Perlick forward seal design again.

Initial Intertap impressions: The stainless steel on the main faucet body is actually chrome-plated stainless (that's why it's so shiny, different from the screw-on spouts). As-received, the chrome was flaking off inside the body of the faucet. I scrubbed at it with a brush and got most of it out, but I was disappointed.

Another issue: Before use I disassembled the faucets, cleaned them in warm PBW, then re-assembled (with a light coating of lube). I then poured a Witbier at 18 psi and found that beer leaked through the bonnet (i.e. the connection to the handle / lever). I tightened down the bonnet cap as hard as I could (even resorted to a wrench) but it still leaked. I had some discussion with the manufacturer (Keg King in Australia) and they said that they've sold ~15,000 faucets without anyone complaining about leaks, but they would send me two replacement gasket sets anyway. They are friendly people and the gaskets were a nice gesture, but not sufficient to stop the leak.

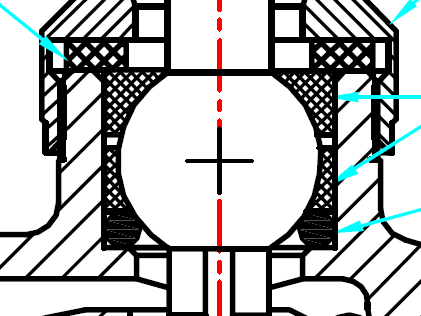

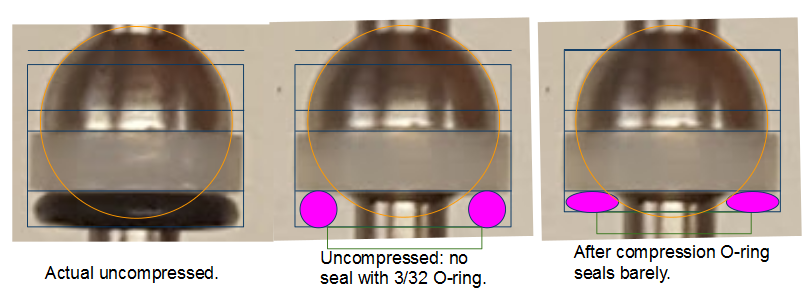

I carefully studied the design and discovered that the lower-most o-ring (below the lever ball) doesn't make a good seal with the lever ball. Keg King confirmed this, saying that the seal is actually made between the ball and the nylon ball washer.

/Side note: in the reference design drawing (pdf on their website), the lower ball o-ring is clearly making contact with the ball, and I think if they actually used the parts they show in that drawing it would work. The issue is that the upper and lower ball washers are generic parts (from the ubiquitous rear-sealing bar faucets) and don't match the design. So, the lower o-ring sits too far away from the ball and doesn't make good contact wit the ball. /end side note

Also, I noticed that out-of-the-box there was a LOT of lube on the ball washers and o-rings, so I think that their design relies on having enough lube to seal properly (again, I'm referring to the seal to the lever handle, not the main faucet seal).

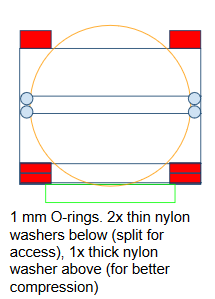

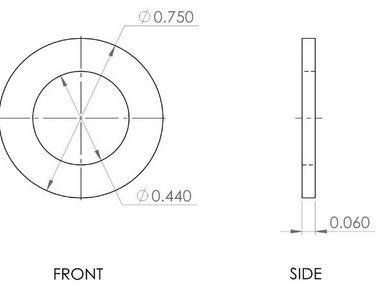

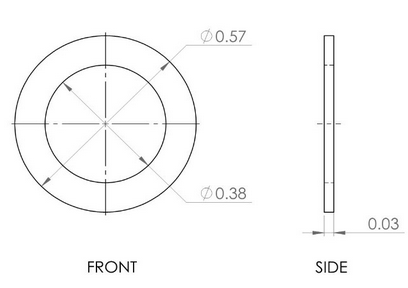

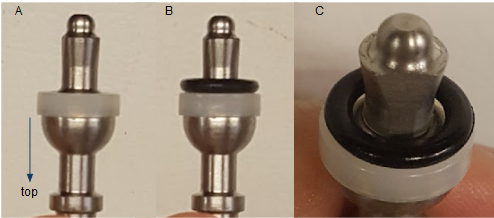

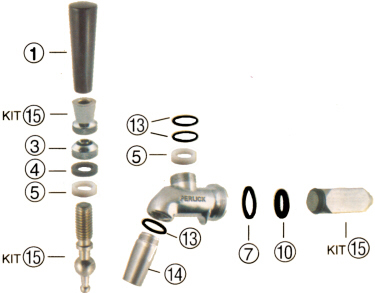

I don't think that's a good design, so I made a modification that works really well: I removed the round o-ring from below the ball washers and replaced it with a hard nylon flat washer (actually two thin ones). Then I put two thin o-rings (1 mm thick, 14.5 mm OD) between the two nylon ball washers. Finally, I added another nylon flat washer right below the bonnet cap as an additional spacer. The two o-rings are the main liquid seal, with the nylon ball washers used only to provide a mechanical seat in which the ball rotates, and the nylon flat washers act only as spacers. This (the sealing double o-ring between two ball washers) is basically the design of the Perlick 425.

The faucet handles work perfectly now, sealing with just a thin coat of lube and very little force, so now I'm happy with the Intertap faucets (price and quality). If I could mashup the perfect faucet it would be: the lever ball seat of the Perlick 630SS with the shuttle forward seal design of the Intertap / ventmatics. And, delete the Chrome plating from the stainless.

Side note: I'm happy with the flow control. Very convenient, with 3 feet of 1/4 tubing and I've poured 5 psi bitters and 21 psi hefeweizens without changing the line.

Initial Intertap impressions: The stainless steel on the main faucet body is actually chrome-plated stainless (that's why it's so shiny, different from the screw-on spouts). As-received, the chrome was flaking off inside the body of the faucet. I scrubbed at it with a brush and got most of it out, but I was disappointed.

Another issue: Before use I disassembled the faucets, cleaned them in warm PBW, then re-assembled (with a light coating of lube). I then poured a Witbier at 18 psi and found that beer leaked through the bonnet (i.e. the connection to the handle / lever). I tightened down the bonnet cap as hard as I could (even resorted to a wrench) but it still leaked. I had some discussion with the manufacturer (Keg King in Australia) and they said that they've sold ~15,000 faucets without anyone complaining about leaks, but they would send me two replacement gasket sets anyway. They are friendly people and the gaskets were a nice gesture, but not sufficient to stop the leak.

I carefully studied the design and discovered that the lower-most o-ring (below the lever ball) doesn't make a good seal with the lever ball. Keg King confirmed this, saying that the seal is actually made between the ball and the nylon ball washer.

/Side note: in the reference design drawing (pdf on their website), the lower ball o-ring is clearly making contact with the ball, and I think if they actually used the parts they show in that drawing it would work. The issue is that the upper and lower ball washers are generic parts (from the ubiquitous rear-sealing bar faucets) and don't match the design. So, the lower o-ring sits too far away from the ball and doesn't make good contact wit the ball. /end side note

Also, I noticed that out-of-the-box there was a LOT of lube on the ball washers and o-rings, so I think that their design relies on having enough lube to seal properly (again, I'm referring to the seal to the lever handle, not the main faucet seal).

I don't think that's a good design, so I made a modification that works really well: I removed the round o-ring from below the ball washers and replaced it with a hard nylon flat washer (actually two thin ones). Then I put two thin o-rings (1 mm thick, 14.5 mm OD) between the two nylon ball washers. Finally, I added another nylon flat washer right below the bonnet cap as an additional spacer. The two o-rings are the main liquid seal, with the nylon ball washers used only to provide a mechanical seat in which the ball rotates, and the nylon flat washers act only as spacers. This (the sealing double o-ring between two ball washers) is basically the design of the Perlick 425.

The faucet handles work perfectly now, sealing with just a thin coat of lube and very little force, so now I'm happy with the Intertap faucets (price and quality). If I could mashup the perfect faucet it would be: the lever ball seat of the Perlick 630SS with the shuttle forward seal design of the Intertap / ventmatics. And, delete the Chrome plating from the stainless.

Side note: I'm happy with the flow control. Very convenient, with 3 feet of 1/4 tubing and I've poured 5 psi bitters and 21 psi hefeweizens without changing the line.