BrewnWKopperKat

ʘ‿ʘ

... continuing with a thought based on my previous reply on alkalinity limits ...

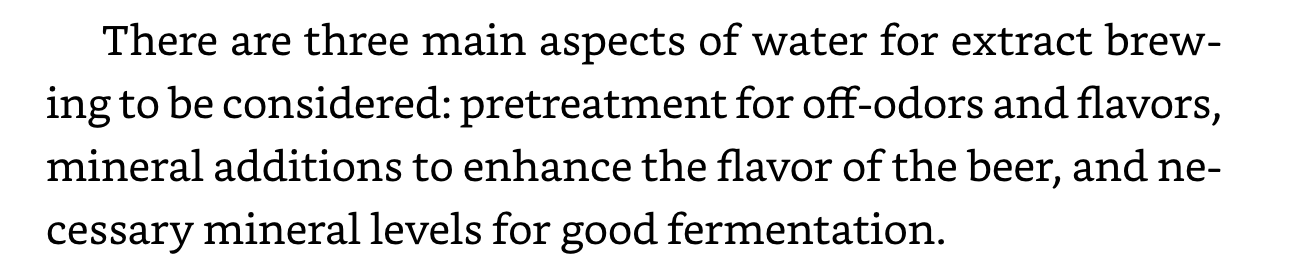

Starting out with DME/LME, there's nothing wrong with using tap water of an unknown mineral content - as long as the beer comes out fine. But if the beer ends up with unexpected flavors, inappropriate mineral content needs to be considered as a source of the unexpected flavors.

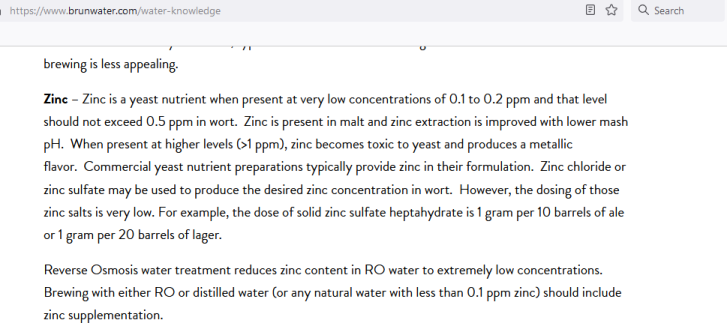

Starting with distilled/RO/low mineral water is one way to avoid the troubleshooting step.

If mineral content of the tap water is known, there appears to be information (note: this is speculation) in a couple of places that can be used to establish rough ppm ranges for good vs poor tap water. Once this is known, some of the techniques that people use to dilute minerals / alkalinity may (again: this is speculation) be appropriate for adjusting tap water when brewing with DME/LME.

Starting out with DME/LME, there's nothing wrong with using tap water of an unknown mineral content - as long as the beer comes out fine. But if the beer ends up with unexpected flavors, inappropriate mineral content needs to be considered as a source of the unexpected flavors.

Starting with distilled/RO/low mineral water is one way to avoid the troubleshooting step.

If mineral content of the tap water is known, there appears to be information (note: this is speculation) in a couple of places that can be used to establish rough ppm ranges for good vs poor tap water. Once this is known, some of the techniques that people use to dilute minerals / alkalinity may (again: this is speculation) be appropriate for adjusting tap water when brewing with DME/LME.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)