I've been running this chiller for a bit over a year now and it's worked great for me. I'm now having issues and wondering if anyone has any hands on experience with this. I reached out to morebeer and I'm currently waiting for information from them. However, initial thoughts from them is that the temp probe in the glycol reservoir is corroded or misplaced and needs to be cleaned.

What I'm experiencing....

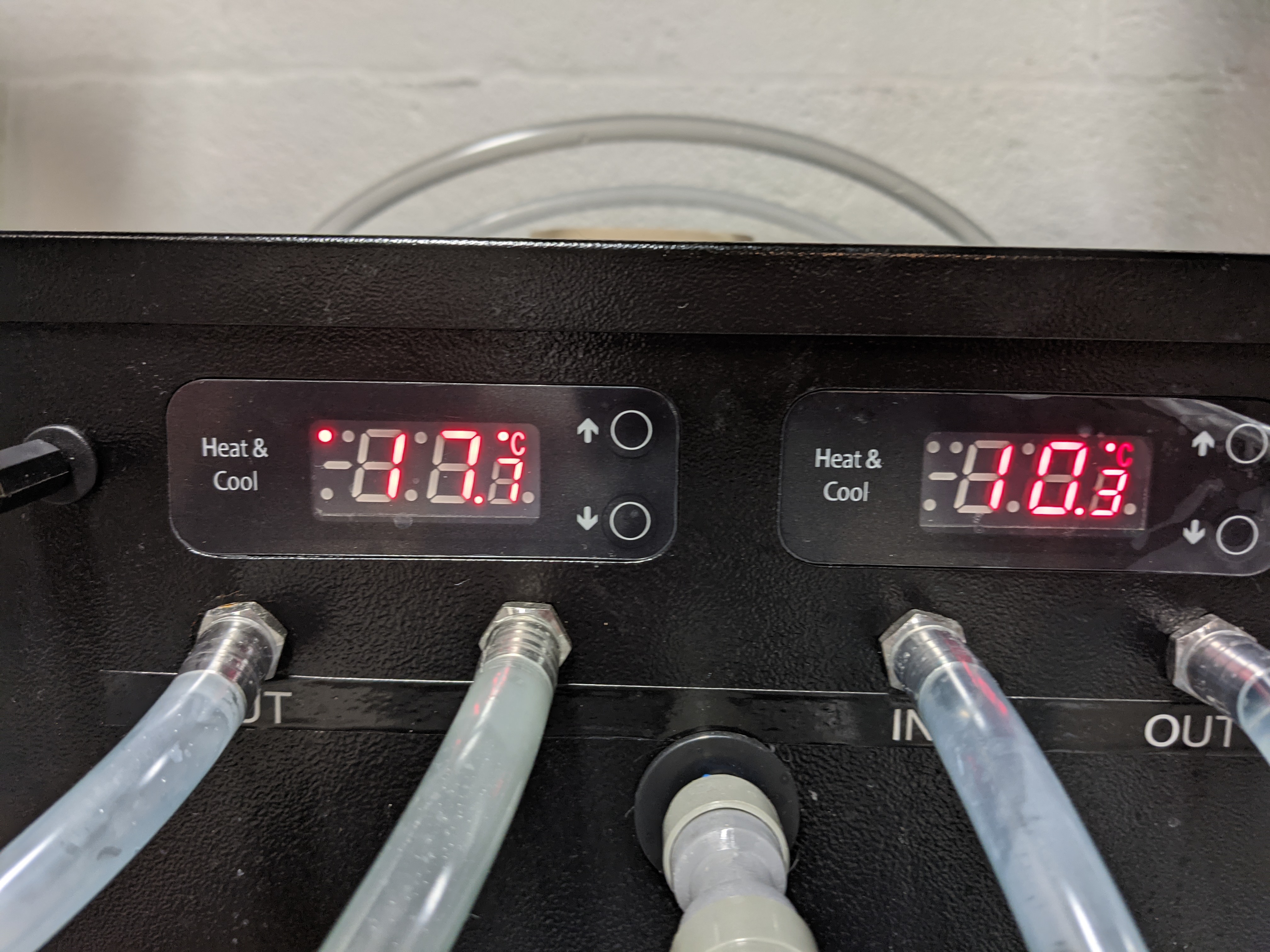

- If pump to fermenter is running at the same time as the unit is cooling the glycol reservoir, the stc1000 main controller on the glycol reservoir fluctuates wildly. It'll bounce all over the place making 2-3C jumps back and forth. It'll eventually start plummeting until it says like -21C and then all of the sudden it errors out with "EE".

- If I run the pump separately from the glycol reservoir, it works fine and does it's thing. I have to make little drops of 2-3C and it seems to handle it ok.

Unfortunately, I'm trying to crash a NEIPA at 2oz/gallon (17 gallons in tank) so I really need to get to cold crash temps but not sure if it will do it in this condition. I've successfully gotten it to 45F as of this morning.

Questions....

1. MoreBeer has stated that I need to locate the temp probe in the glycol reservoir and clean it. Anyone have any pictures of where this thing is?

- They've also stated that it could have been displaced but can't tell me where it SHOULD be placed. Anyone know this?

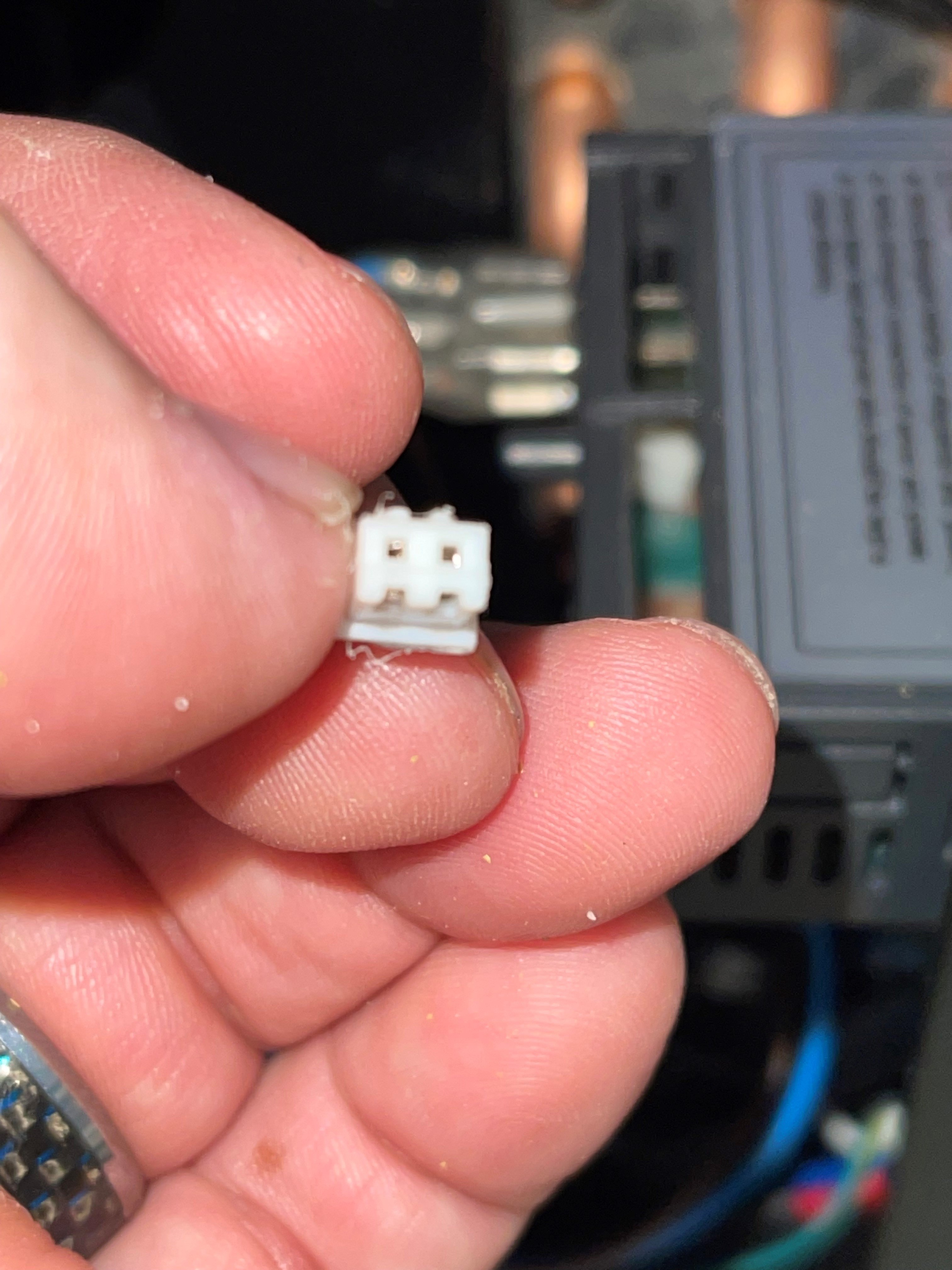

2. I do not have a multi meter. Would it be an easy task to just replace the probe on the stc1000 to see if it helps?

I'm sure there will be more questions as we go. Thanks in advance.

What I'm experiencing....

- If pump to fermenter is running at the same time as the unit is cooling the glycol reservoir, the stc1000 main controller on the glycol reservoir fluctuates wildly. It'll bounce all over the place making 2-3C jumps back and forth. It'll eventually start plummeting until it says like -21C and then all of the sudden it errors out with "EE".

- If I run the pump separately from the glycol reservoir, it works fine and does it's thing. I have to make little drops of 2-3C and it seems to handle it ok.

Unfortunately, I'm trying to crash a NEIPA at 2oz/gallon (17 gallons in tank) so I really need to get to cold crash temps but not sure if it will do it in this condition. I've successfully gotten it to 45F as of this morning.

Questions....

1. MoreBeer has stated that I need to locate the temp probe in the glycol reservoir and clean it. Anyone have any pictures of where this thing is?

- They've also stated that it could have been displaced but can't tell me where it SHOULD be placed. Anyone know this?

2. I do not have a multi meter. Would it be an easy task to just replace the probe on the stc1000 to see if it helps?

I'm sure there will be more questions as we go. Thanks in advance.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)