Car Ramrod

Well-Known Member

- Joined

- Jan 24, 2019

- Messages

- 117

- Reaction score

- 16

Not sure what happened to that, but I've uploaded it again. I did not put any thought into the upload, but it's the same piece.@LBussy hey I finally bought a 3d printer as was looking for your design of the temp probe holder on thingaverse. And it looks like you might have removed it. Did it not work as expected?

I hate to say "you're not asking the right question," but, you're not asking the right question.Does Fermentrack run on an ESP8266?

I hate to say "you're not asking the right question," but, you're not asking the right question.

This thread is BrewPi specific. Fermentrack is a different UI written to serve the application. It is a separate thread. Both Fermentrack and BrewPi Remix connect to a controller. Both support the original Arduino Uno, as well as the ESP8266. So, BrewPi (the firmware) runs on the ESP8266 as well as the Arduino Uno. You'd connect either of those to either BrewPi Remix or Fermentrack.

Hopefully, that makes sense.

That construct is embodied in BrewPiLess, which does not use the Pi.I am trying to minimise the footprint on some of my installations and if I can use an ESP8266 in place of a Pi then I'm all ears.

@day_trippr I think you and @gromitdj are probably correct.If everything works fine except you eventually weld the points on the Cold side relay module, I would suspect the relay module rating isn't up to par with the load it is trying to switch. You could add a slaved relay with much higher current rating - I did this for my keezer - and never have to worry about it again...

Cheers!

This is what I've sketched up, but based on your "NO points" comment I have a feeling it isn't correct.hah! No, "SainSmart" isn't the "SS" in "SSR"

SSR = Solid State Relay

So I think we're all on the same page now. There are relays used, and evidently the points are being welded on the Cold relay.

That indicates the current draw (at least on start-up) on the load is far in excess of what the relay can handle.

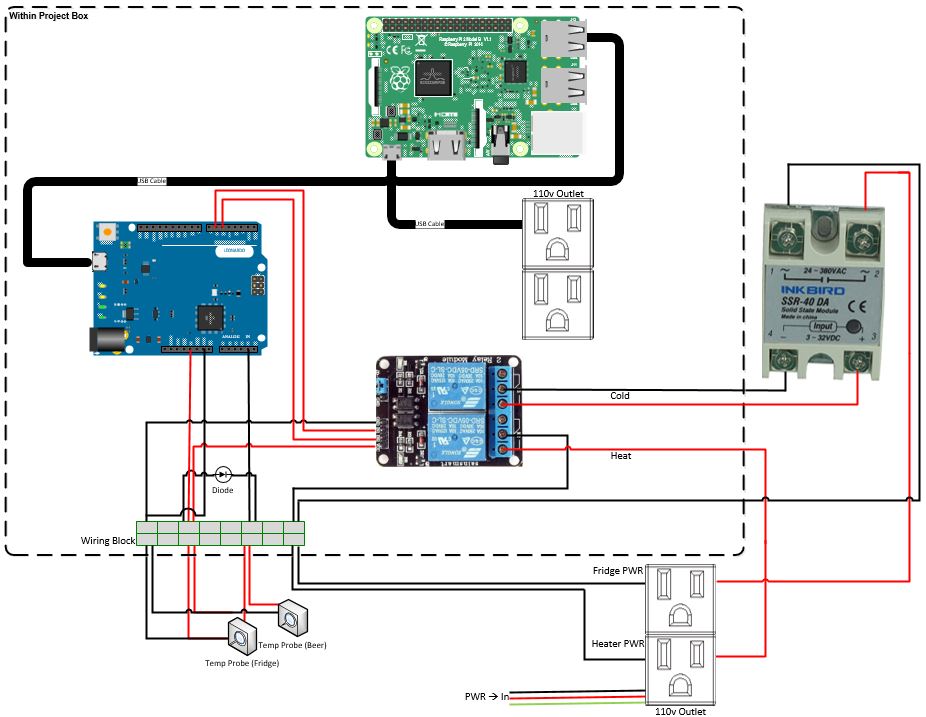

Now, with a new/fully functional dual relay module, you could route 5V (drawn off the Arduino) through the Cold relay NO points and send that to your Inkbird SSR control input, and use that hunky chunk of Si to switch your compressor. Or - and this depends on the control input loading provided by that SSR - you could skip the relay entirely and control the SSR directly from the Arduino...

Cheers!