Brewski_59

https://www.facebook.com/narcosisbrew/

Glad you pointed this out. Fuzze this would be a bad idea to try.

Hi guys. I have tried to search this thread, but to no avail. Simple question: is it possible to make the Arduino Uno communicate with the web server, in my case a VM on a NAS, over ethernet rather than USB using, for instance, a Ethernet Shield W5100? My NAS is in another room and I already have RJ45 sockets in my fermentation room.

If that shield can be run in a "transparent" mode such that the Uno still thinks the world is a serial port, it should work. Some of us are using esp8266 wifi-serial bridges to link Unos with BrewPi hosts, and that works because the Uno still "speaks serial" and the esp8266 does all the heavy lifting...

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

[...]Can you take a look at the attached schematic and let me know if I'm on the right track before we start tackling routing stuff on the board?[...]

Ok, I reviewed the Eagle schematic against my latest shield schematic. Other than having the 16-pin LCD connector sectioned as 1-12 and 1-4 (with 1-4 corresponding to 13-16), and the lack of the p-channel FET for the backlight dimming function (and the bits for the panel LED support) it looks to be an accurate copy.

I would recommend adding the p-FET, perhaps as an option with a wire jumper around it if the user opts not to install it. I have all my minions using the backlight dimmer function and prefer it to having them constantly glowing.

Otherwise I think you're good to get into layout...

Cheers!

The LEDs on my minions are derived from a Love TSS2 implementation I did before BrewPi ever arrived on the scene.

I provided individual SPST/Center Off switches for both the Heat and Cool functions, with each switch selecting the AC mode (ie: either TSS2 controlled AC, Always On, or Always Off). This proved to be so useful that I did something similar with my BrewPi minions, except I used DPDT/Center Off switches, with one half of each switch controlling the AC mode for the function, and the other half of each switch controlling the state of the associated LED.

Here's the wiring scheme...

I located the two "pull-up" resistors (actually, current limiting resistors in the 200-300 ohm range) on my shield design because it's the handiest place for them. Wrt a pcb layout, they're trivial, and it's always easier to have something in etch that's not used than it is to wish you had something in etch

Cheers!

ok so i am back on this thread again. honestly I gave up on this build, because the software was just too complicated for me.

Now NOOBS is downloadable and I can forsee this new project in the future. I knew it was a matter of time when people smarter than me would figure something like this out and put it together in a software package.

So I have read about half of this thread, thats how exiceted I was at the start, so my question is.......... is the hardware configuration the same for this build as it is on the first page? I remember seeing something with a minor tweek somewhere before half this thread.

courious minds want to know

edit: I was able to change the /var/www/html to /var/www and finished the install. I received the message to enter the IP address into the web interface. I did the update sudo python updater.py and recived the message ***Done updating BrewPi****. But when I go to the Rpi IP address I get Not Found.

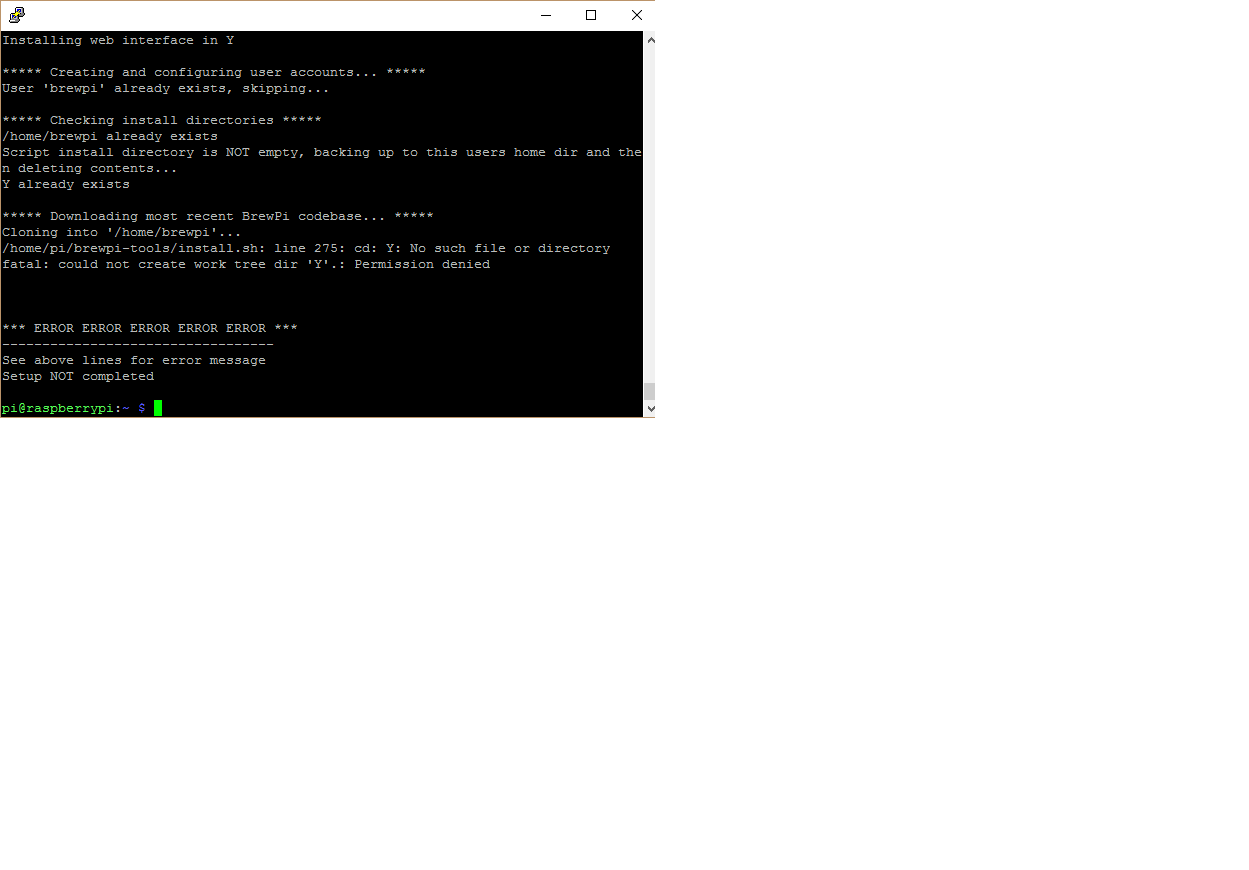

I have been working on this over the weekend and keep getting an error message when doing the automated install.

When the process gets to Downloading most recent BrewPi Codebase it gets an error stating no such file or directory.

Has anyone run into this before?

It appears somehow you actually entered in Y as a directory to install things. You can see on the very first line its installing the Web interface into a directory named Y.

When you run these scripts simply hit enter when they ask you what path to install into and it uses the default. The default is /home/brewpi and /var/www for the webpage stuff. Only answer Y/N if it explicitly asks for those, in this case you entered Y when it was asking you for a directory to install to.

It appears somehow you actually entered in Y as a directory to install things. You can see on the very first line its installing the Web interface into a directory named Y.

When you run these scripts simply hit enter when they ask you what path to install into and it uses the default. The default is /home/brewpi and /var/www for the webpage stuff. Only answer Y/N if it explicitly asks for those, in this case you entered Y when it was asking you for a directory to install to.

Just wondering,

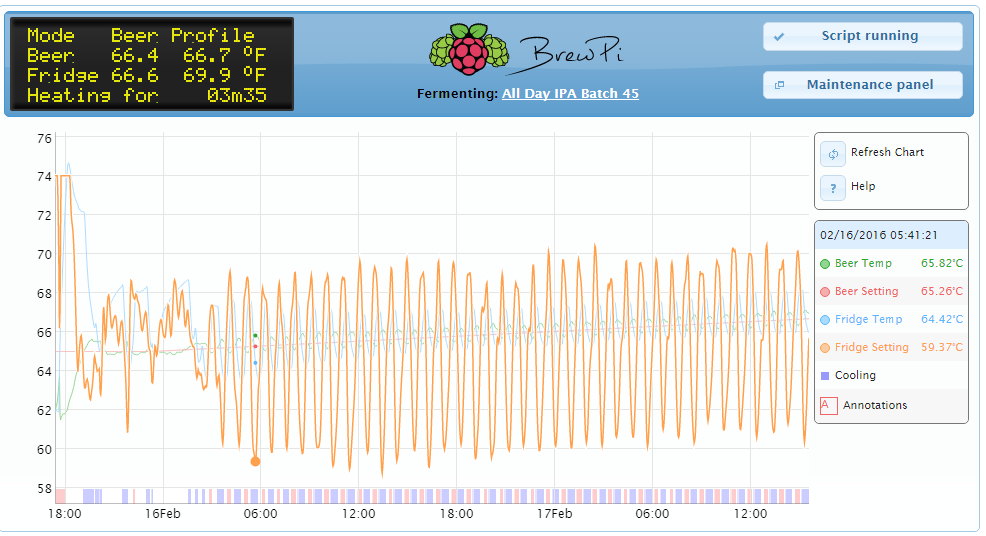

On my chart it shows different colors on the bottom

For cooling it starts out violet and then changes to blue/purple

For heating it starts out pinkish and then turns red

Are the off colors the waiting periods and the blue red the actual time on or is that indicating a ramping of temp while running?

(He said pinkish)

For the temperature probes I suggest you get one working first then add the others.

There are two parts to the connection. The first is on the 'controller' side. There are three connections, +5V, Data and Ground (0V). The resistor goes from Data to +5V. You only need one resistor.

The second part is the sensors themselves. They are strung out on parallel wires. Basically, each one gets a connection to +5V, Data and Ground. Make sure you get the pins the right way round.

If you can get a single sensor working then you can get several in parallel working (with only one pull-up resistor).

Thanks for replying so quickly, I'll try just the one tonight. Just out of interest, when you twist the wires together from the two sensors and stick them in the same slot in the controller, then have one wire going from the controller to the Arduino, this one wire can still separate out the two signals and the Arduino can understand it as two? Such a stupid question but this is my first time wiring anything and its interesting that the two wires can be distinguished after being hooked up this way.

Anybody got any general wiring tips? I can't get my temp probes to show up, I'm using a connector like in the second schematic and I've wrapped the necessary wires around the resistor. With the other ones I've twisted them together before screwing them down in the connector. Is this the correct way to use a connector and resistor? I've checked the amazon listing where I bought the probes and they tell you which wire is which so I don't think its that. At a loss here

As a note I run the pump constant so the system behaves more like a fermenter in a chamber.

I am reluctant to use the constant fridge set point. In watching my other ferments I have seen an 8 or 9 degree difference between fridge and beer temp at the peak of fermentation. I could try in constant beer mode to see if it hones in a little closer.

I have a also thought about using as little water as possible to keep it from having a fly wheel effect with the mass of the water.

I don't plan on having it connected to the internet once everything is running.

If you use the net install as i suggested, you'll need internet access to install the operating system. Additionally, You'll need network access unless you plan on having a permanent monitor and keyboard attached. Or want to attach them every time you want to check it's status.

In my opinion, the beauty of the system is being able to monitor and adjust the fermentation from any web browser on your home network.

Yeah I plan on the install and config to be done before I move it to the brewhouse, but network access there isn't feasible unless I add a wifi dongle, which I am not planning on at this time. I may run a cable to an old crt TV for monitoring through a converter. I just wanted to make sure the old PC wasn't too much of a dinosaur.