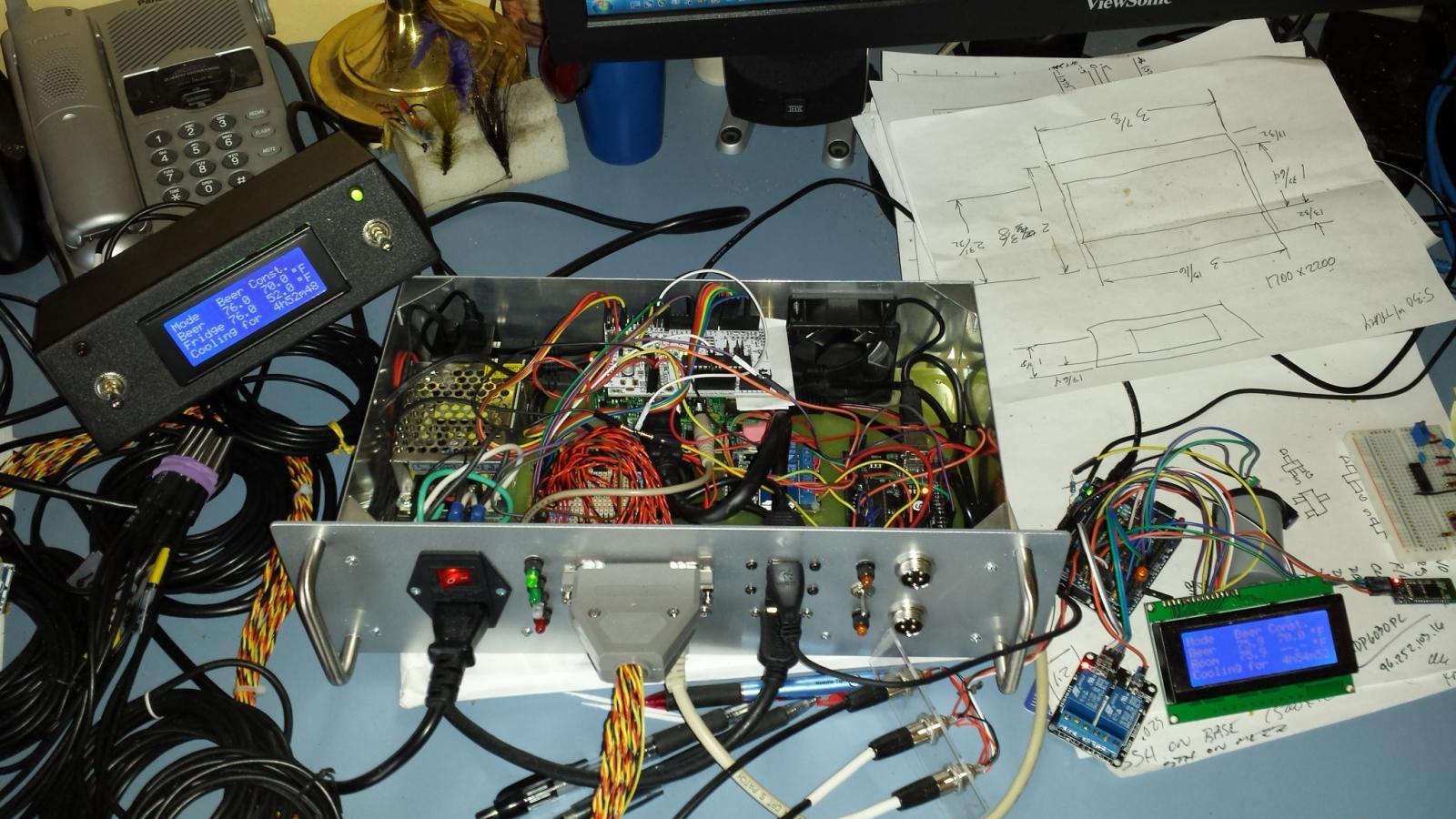

**** Arduino Program script started ****

Arduino Home /usr/share/arduino/

Settings will not be restored

Devices will not be restored

Checking old version before programming.

Found BrewPi v0.2.4, running commit 00000000, on an Arduino standard on port /dev/ttyACM0

Requesting old settings from Arduino...

Saving old settings to file oldAvrSettings-Mar-01-2015-08-48-45.json

Loading programming settings from board.txt

Checking hex file size with avr-size...

Program size: 25666 bytes out of max 32256

Programming Arduino with avrdude: /usr/share/arduino/hardware/tools/avrdude -F -e -p atmega328p -c arduino -b 115200 -P /dev/ttyACM0 -U flash:w:"brewpi_avr.hex" -C /usr/share/arduino/hardware/tools/avrdude.conf

result of invoking avrdude:

avrdude: AVR device initialized and ready to accept instructions

Reading | ################################################## | 100% 0.00s

avrdude: Device signature = 0x1e950f

avrdude: erasing chip

avrdude: reading input file "brewpi_avr.hex"

avrdude: input file brewpi_avr.hex auto detected as Intel Hex

avrdude: writing flash (25666 bytes):

Writing | ################################################## | 100% 4.95s

avrdude: 25666 bytes of flash written

avrdude: verifying flash memory against brewpi_avr.hex:

avrdude: load data flash data from input file brewpi_avr.hex:

avrdude: input file brewpi_avr.hex auto detected as Intel Hex

avrdude: input file brewpi_avr.hex contains 25666 bytes

avrdude: reading on-chip flash data:

Reading | ################################################## | 100% 3.95s

avrdude: verifying ...

avrdude: 25666 bytes of flash verified

avrdude done. Thank you.

avrdude done!

Giving the Arduino a few seconds to power up...

Back up in 5...

Back up in 4...

Back up in 3...

Back up in 2...

Back up in 1...

Back up in 0...

Now checking which settings and devices can be restored...

Checking new version: Found BrewPi v0.2.4, running commit 00000000, on an Arduino standard on port /dev/ttyACM0

Resetting EEPROM to default settings

Arduino debug message: INFO MESSAGE 15: EEPROM initialized

No settings to restore!

No devices to restore!

**** Program script done! ****

If you started the program script from the web interface, BrewPi will restart automatically

Mar 01 2015 08:49:12 New program uploaded to Arduino, script will restart

Mar 01 2015 08:49:19 Notification: Script started for beer 'My First BrewPi Run'

Mar 01 2015 08:49:30 Found BrewPi v0.2.4, running commit 00000000, on an Arduino standard on port /dev/ttyACM0

Mar 01 2015 08:49:35 Installed devices received: []

Mar 01 2015 08:49:35 JSON decode error: Expecting object: line 1 column 1 (char 1)

Mar 01 2015 08:49:35 Line received was: h:[D:{"logType":"I","logID":10,"V":[-1]}

Mar 01 2015 08:49:35 Cannot process line from Arduino: {"i":-1,"t":0,"c":1,"b":0,"f":0,"h":2,"d":0,"p":10,"a":"28DE243E060000A2","j": 0.000}D:{"logType":"I","logID":10,"V":[-1]}

Mar 01 2015 08:49:35 Cannot process line from Arduino: ,{"i":-1,"t":0,"c":1,"b":0,"f":0,"h":2,"d":0,"p":11,"a":"28A2B83F0600005E","j": 0.000}D:{"logType":"I","logID":10,"V":[-1]}

Mar 01 2015 08:49:35 Cannot process line from Arduino: ,{"i":-1,"t":0,"c":1,"b":0,"f":0,"h":1,"d":0,"p":13,"x":1}D:{"logType":"I","logID":10,"V":[-1]}

Mar 01 2015 08:49:35 Cannot process line from Arduino: ,{"i":-1,"t":0,"c":1,"b":0,"f":0,"h":1,"d":0,"p":12,"x":1}]

Mar 01 2015 08:49:42 Installed devices received: []

Mar 01 2015 08:49:42 JSON decode error: Expecting object: line 1 column 1 (char 1)

Mar 01 2015 08:49:42 Line received was: h:[D:{"logType":"I","logID":10,"V":[-1]}

Mar 01 2015 08:49:42 Cannot process line from Arduino: {"i":-1,"t":0,"c":1,"b":0,"f":0,"h":2,"d":0,"p":10,"a":"28DE243E060000A2","j": 0.000}D:{"logType":"I","logID":10,"V":[-1]}

Mar 01 2015 08:49:42 Cannot process line from Arduino: ,{"i":-1,"t":0,"c":1,"b":0,"f":0,"h":2,"d":0,"p":11,"a":"28A2B83F0600005E","j": 0.000}D:{"logType":"I","logID":10,"V":[-1]}

Mar 01 2015 08:49:42 Cannot process line from Arduino: ,{"i":-1,"t":0,"c":1,"b":0,"f":0,"h":1,"d":0,"p":13,"x":1}D:{"logType":"I","logID":10,"V":[-1]}

Mar 01 2015 08:49:42 Cannot process line from Arduino: ,{"i":-1,"t":0,"c":1,"b":0,"f":0,"h":1,"d":0,"p":12,"x":1}]

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)