Dgonza9, I appreciate your opinion. Only problem is that I don't think I completely understand how a RIMS system works. Could you dummy it down for me?

thanks

RIMS = Recirculating Infusion Mash.

Basically, you recirculate during the mash. The recirculation flows from your mash tun to your pump, then into a stainless steel tube with two tees on each end. In one tee you screw in an element. In the other, you screw in a temperature probe. Then you route the flow back to your mash tun.

The element and probe are wired to a PID and SSR that drives the element. You just program in your set temperature and the PID figures out how to fire your element in short bursts so that you won't overshoot the temperature. You recirculate during the mash and the PID maintains the temperature.

Here's a shot of one of my mashes. On top is the actual temp. Below my set value. The PID kept my mash at nearly the exact temperature the entire time.

Here's a shot of the RIMS Tube. The copper pipe is just part of hard plumbing that goes from my mash tun. Nothing to do with the tube.

Here's a shot of the control panel. I wired my pump and ventilation fan to it as well, but you don't have to.

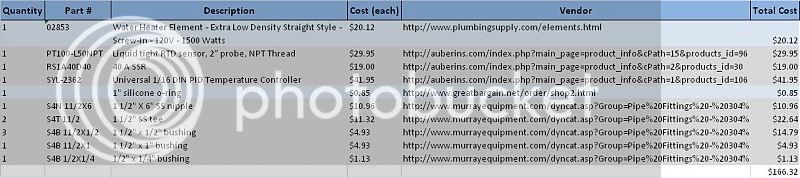

Here's a parts list.

Do a search for "RIMS for DUMMIES" and you'll have some fun reading.

I think that wiring up a PID, SSR, and making holes for your control panel, etc. can be pretty time consuming and even challenging. It took a lot more time than I imagined it would. So it isn't exactly a quick project. But if you are looking to precisely control your mash temp, it's a great way to go. The only difference is where you mount your element and probe, in a tube rather than in your keggle.

It has a mighty advantage over a johnson controller that just turns off when it reaches a temperature. That will likely overshoot. The PID will figure out how to fire the element in short little bursts so it hits your mash temp dead on and then keeps it there. It's pretty cool. May not be what you are looking for, though.

Cheers.