Sean_SA

Well-Known Member

- Joined

- May 24, 2020

- Messages

- 46

- Reaction score

- 6

Hi guys

I have a question and need some advice on grounding the elements on my pots please.

Firstly, I am unable to find a suitable metal enclosure/housing for the element connections. So I'll need to go with a plastic housing. That means I'll need to ground the pots outside the housing.

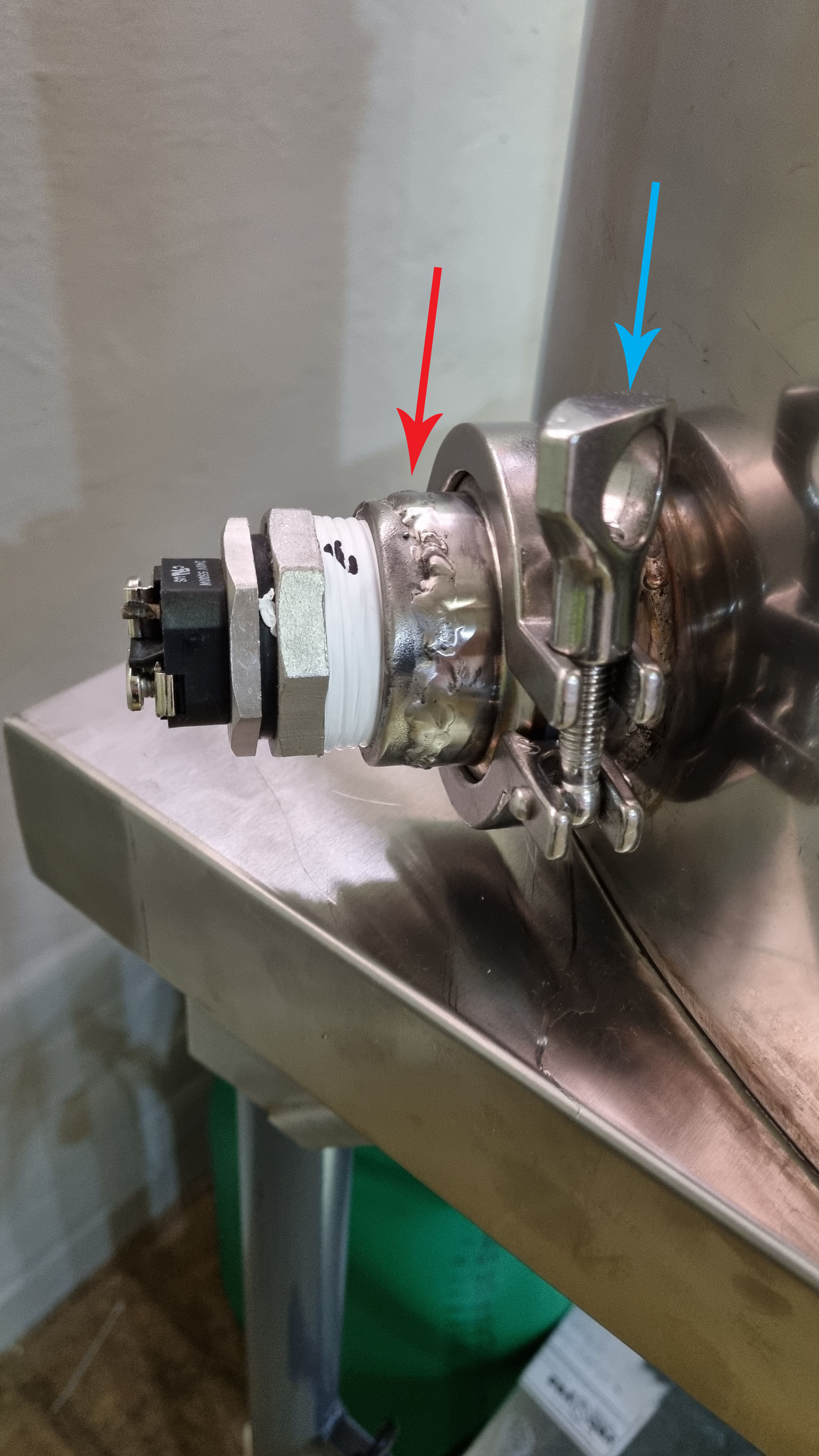

Could I simply wrap the ground wire around the triclamp screw ring (blue arrow in pic below) and keep it fastened with a cable tie or 2. Not a clean solution by any means but seems to make sense to me. Else does anyone perhaps have a more clean looking method they could suggest for my situation. Perhaps putting a lug on top of the triclamp adapter (red arrow in pic below) and using JB weld to bond?

I have a question and need some advice on grounding the elements on my pots please.

Firstly, I am unable to find a suitable metal enclosure/housing for the element connections. So I'll need to go with a plastic housing. That means I'll need to ground the pots outside the housing.

Could I simply wrap the ground wire around the triclamp screw ring (blue arrow in pic below) and keep it fastened with a cable tie or 2. Not a clean solution by any means but seems to make sense to me. Else does anyone perhaps have a more clean looking method they could suggest for my situation. Perhaps putting a lug on top of the triclamp adapter (red arrow in pic below) and using JB weld to bond?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)