- Joined

- Sep 14, 2018

- Messages

- 556

- Reaction score

- 234

I’m cold crashing 7.5 gallons of beer in my CF10, using a homemade glycol chiller.

Yesterday it went down to 33°F. Now it seems stuck at 40°F, although the solution temp is measuring at 14°F.

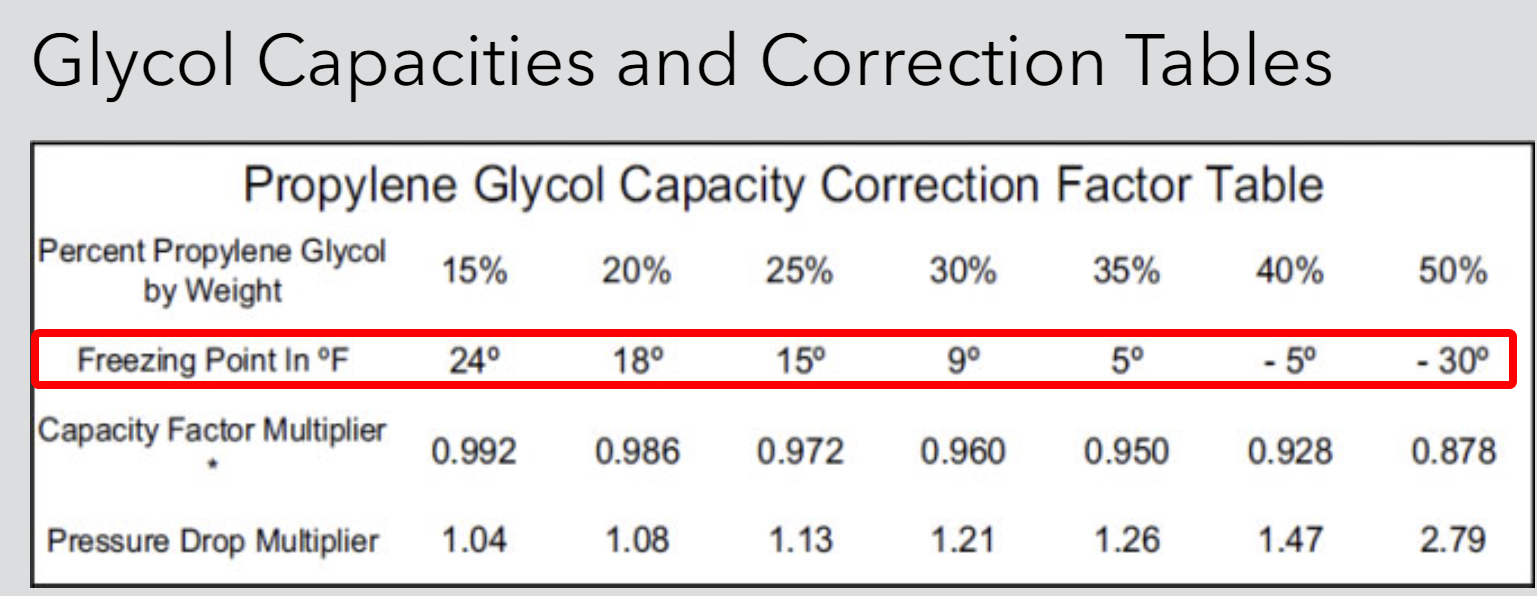

I used the recommended glycol:water ratios, but there’s ice buildup on the evaporating coil. Is this a problem?

As always, thanks!

Yesterday it went down to 33°F. Now it seems stuck at 40°F, although the solution temp is measuring at 14°F.

I used the recommended glycol:water ratios, but there’s ice buildup on the evaporating coil. Is this a problem?

As always, thanks!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)