frodus17

Well-Known Member

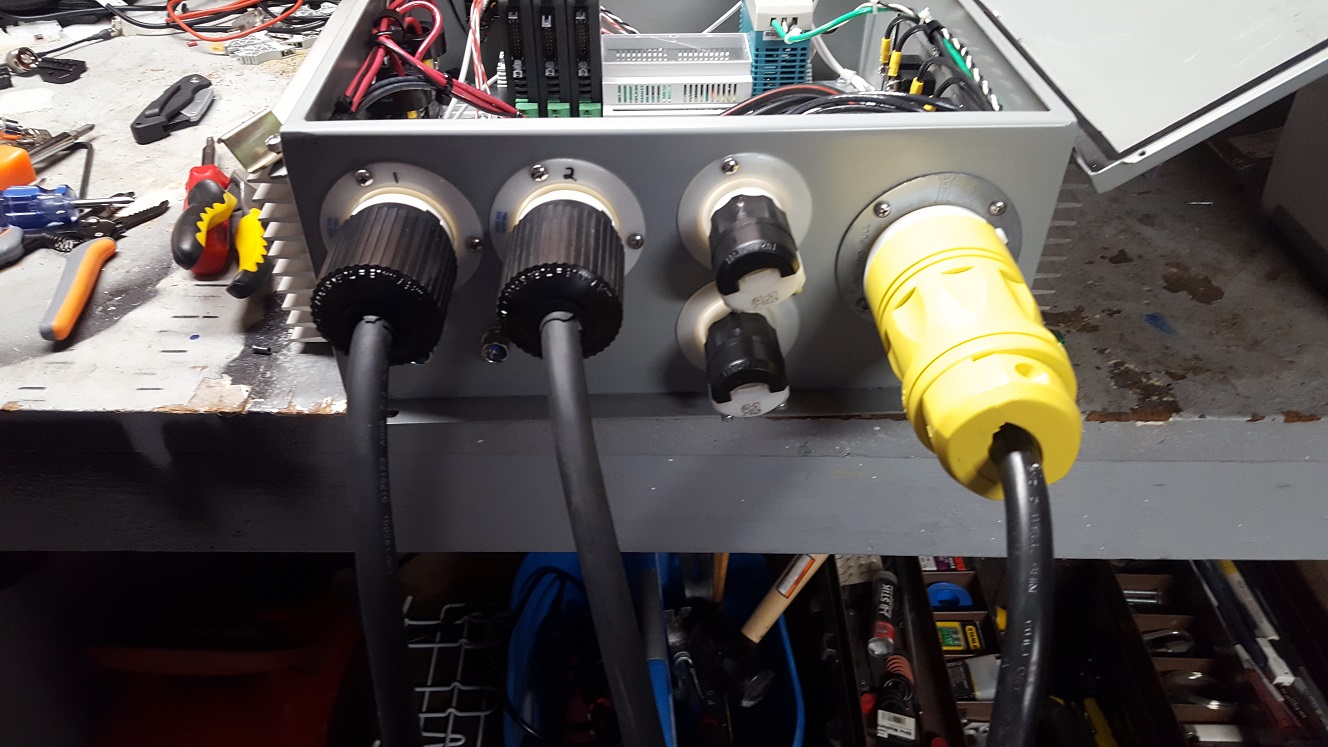

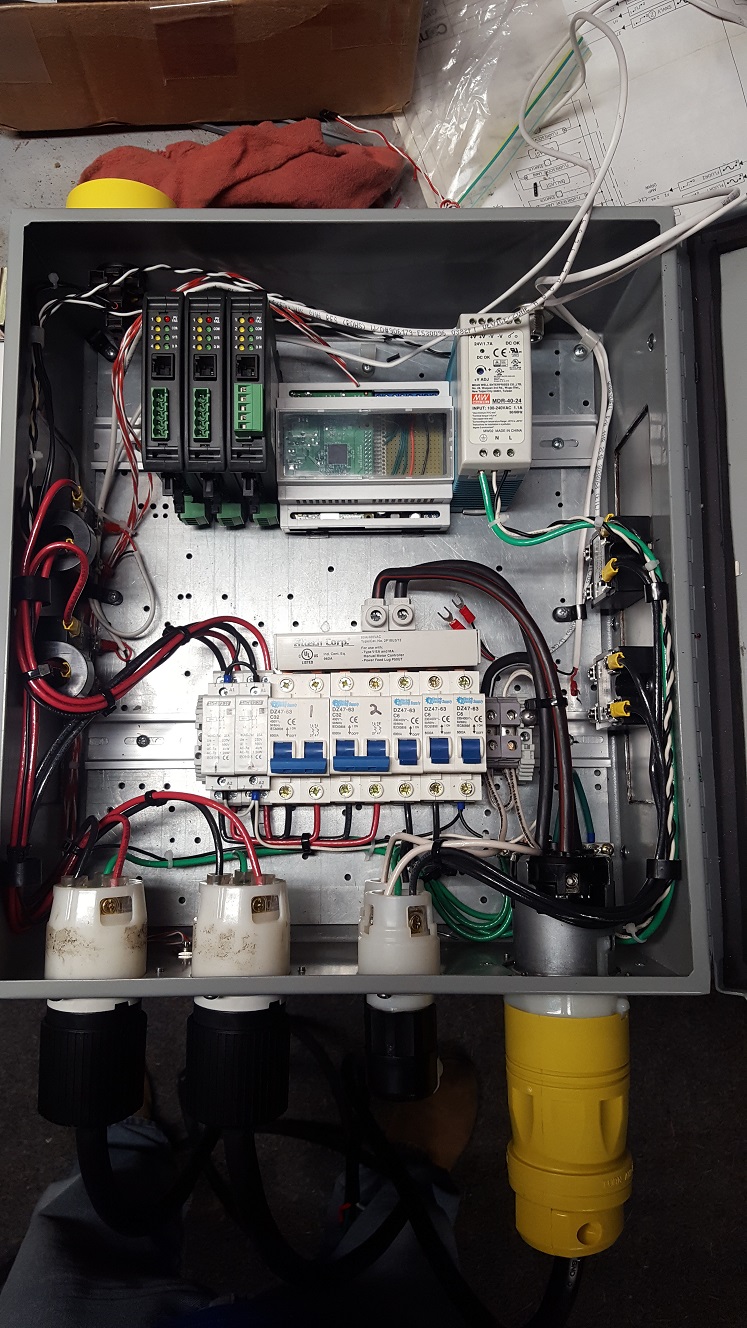

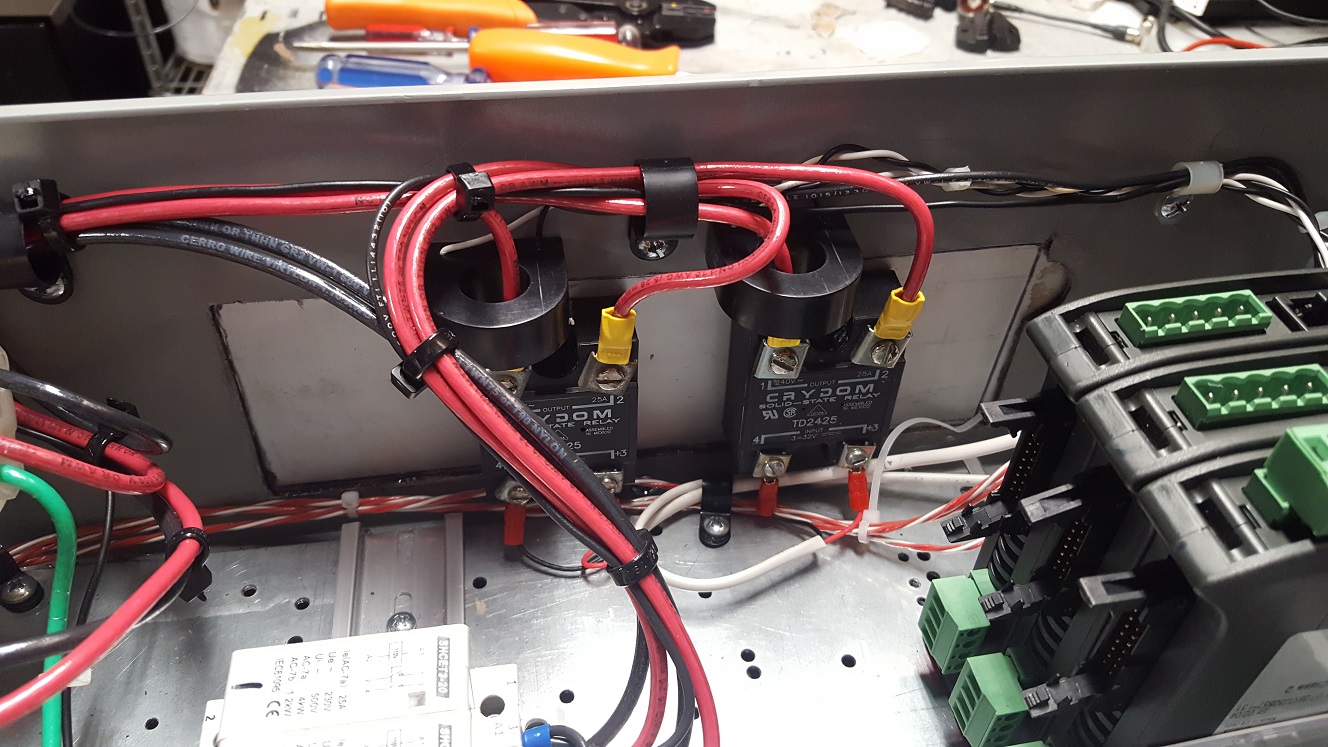

Got a 240V 50A outlet installed below my breaker panel today. Got a GFCI breaker and installed in my breaker box and ran some flex down to a retrofit box. I used a stud/cable finder but I didn't see the cable that was behind, so I cut a little high. Easy to cover over. Wired a 50A stove outlet for L1/L2/N and Ground connections. Tested everything and we're good to go.

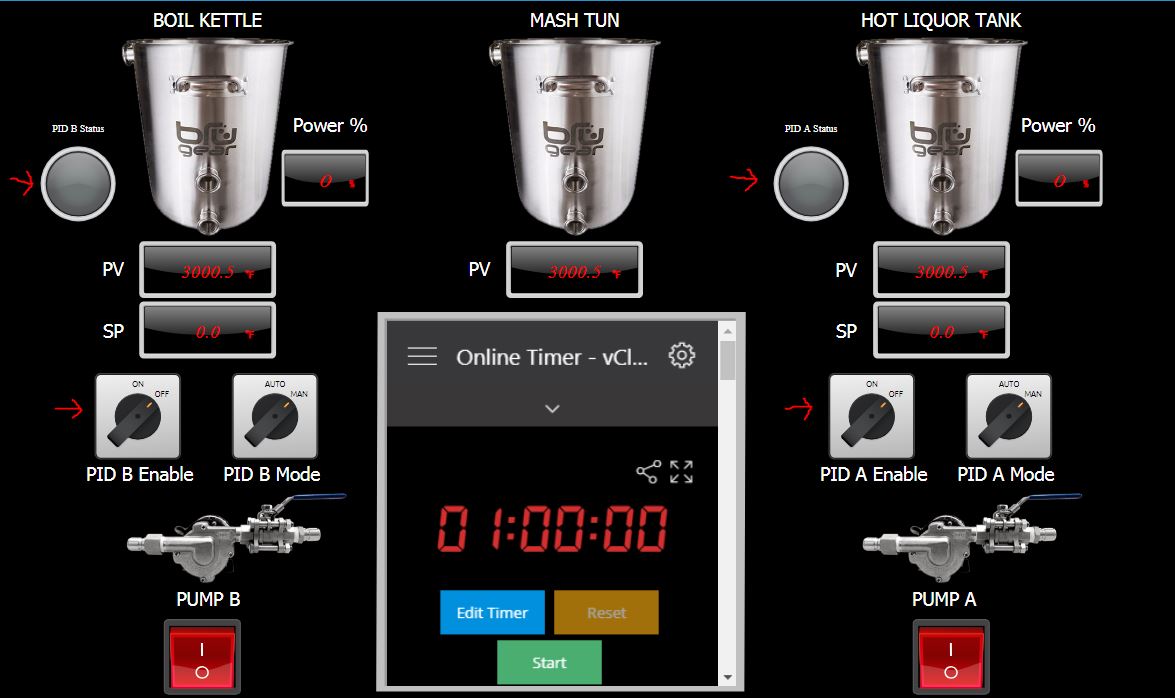

Ordered the last components for my control panel this week, so should be able to finish the build next weekend if all goes well. Also ordered two 4500W elements.

Ordered the last components for my control panel this week, so should be able to finish the build next weekend if all goes well. Also ordered two 4500W elements.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)