- Joined

- Dec 16, 2015

- Messages

- 935

- Reaction score

- 355

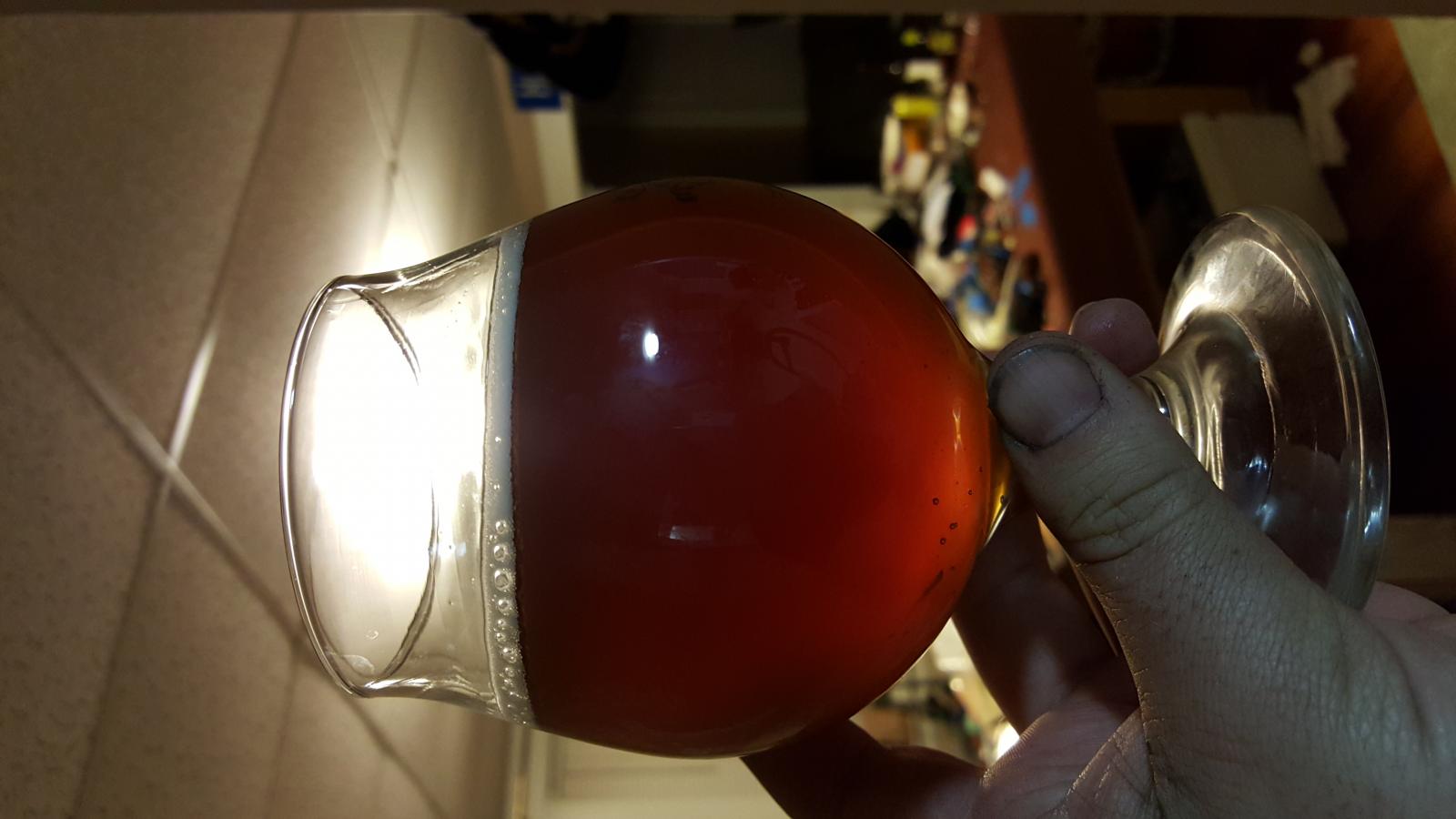

So last night I had my first ever all grain, and first BIAB brew day. Started with a Belgian Pale figuring I should go with something on the easier side. I have an 8.5 gallon pot making 3-3.5 gallon batches. Things started well enough. Hit my mash in water temp, and nailed my mash temp once the grains went in. But first lesson came soon after.

I got the grains out, squeezed them a bit, probably not enough. I thought I was doing well. Looked like my pre-boil volume was right, took a gravity reading, which when adjusted for temperature matched what beersmith said it should. Boil went ok.

Post boil is where I found my issues. My post boil volume was a little high. I think my evaporation rates are lower when it's not pure water, so that will need to be adjusted. I was also crazy off my gravity. Was supposed to hit 1.054, was down at 1.043. I think I have some theories.

Other than missing my gravity, the rest went smooth. My home made immersion chiller is a champ. Boiling to under 80°F in about 15 minutes. It's in the carboy holding steady at 65 and will start ramping up tonight to 70. No noticeable yeast activity yet, but the strain (wyeast 1214) says it may be slow to start. I did make a starter, but mistimed it and activity was done about 12 hours before I needed it. Not worrying, I'll let it have a full day or two to get going before I worry.

Anyway, Had fun and I think I have a good list of what to improve on next time. This should be a fun journey.

- I need a better thermometer. I have a dial thermometer installed in my pot with a 2 or 3 inch probe. Works great when there is no grain in the pot. When there is grain it's heavily affected by clumps of grain around it. Lesson learned, get a good digital and take temps in a few places.

- I need insulation. We didn't do anything to the pot during mash, figuring we'd just see how it did the first time. I ended up having to add heat twice as it would dip 4-5 degrees in roughly 40 minutes. So I'll do something, I like the Reflectix insulation home depot sells.

- I need a better bag. I bought a cheap one on amazon. It was way too big, and not well made. Already tore a hole in it. So, good quality bag here I come.

I got the grains out, squeezed them a bit, probably not enough. I thought I was doing well. Looked like my pre-boil volume was right, took a gravity reading, which when adjusted for temperature matched what beersmith said it should. Boil went ok.

Post boil is where I found my issues. My post boil volume was a little high. I think my evaporation rates are lower when it's not pure water, so that will need to be adjusted. I was also crazy off my gravity. Was supposed to hit 1.054, was down at 1.043. I think I have some theories.

- I need to double crush my grains. The LHBS said it wouldn't be necessary since they had a new mill and a double crush would basically make it flour. I don't buy it, the single crush wasn't that fine. So double next time.

- I need better mash temp control. I have a feeling I over heated it at one point when adding heat.

- I need to do more squeezing, or some sort of sparge. I also need gloves so I can squeeze without acquiring minor burns.

- I need to work out my evaporation a little better and adjust. I may have started with a little bit too much water, and I definitely ended with too much.

- I need to suck it up and get a refractometer. Dealing with samples and temperature compensation with the hydrometer is annoying. I've always believed in simply owning the correct tools, so might as well buy one more.

Other than missing my gravity, the rest went smooth. My home made immersion chiller is a champ. Boiling to under 80°F in about 15 minutes. It's in the carboy holding steady at 65 and will start ramping up tonight to 70. No noticeable yeast activity yet, but the strain (wyeast 1214) says it may be slow to start. I did make a starter, but mistimed it and activity was done about 12 hours before I needed it. Not worrying, I'll let it have a full day or two to get going before I worry.

Anyway, Had fun and I think I have a good list of what to improve on next time. This should be a fun journey.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)