gifty74

Well-Known Member

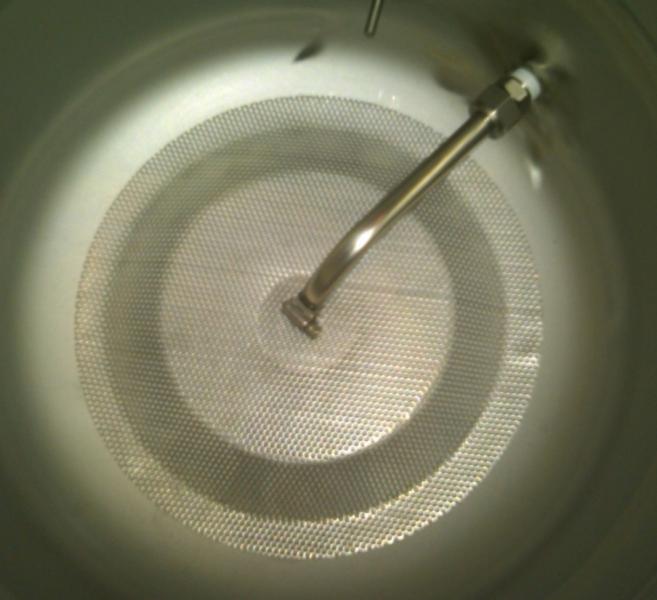

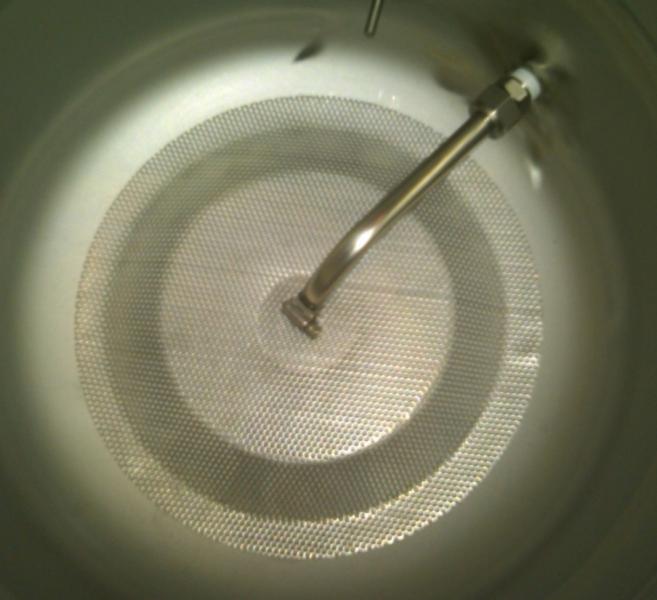

I have a converted keg mash tun with Midwest Supplies mash screen and homemade dip tube to pull from the center (underneath the screen, pics attached). I've been having issues with flow slowing to a trickle during mash recirculation. I had to go in and rouse/scrape the screen during mash to free things up. In the future I do not want to have to worry about how fast I'm pumping, flow slowing, stuck mashes, etc. I had been mashing in a cooler with a manifold that I slit to allow flow and could run that at full pump speed and never had an issue with flow slowing or sticking the mash. A manifold would be a problem with my new direct fired system because the grains are laying right on the bottom of the kettle with no false bottom.

What is everyone using, and are having any issues with flow during recirculation?

I don't want to go to a RIMS tube, but that seems like an option here. Any other thoughts?

What is everyone using, and are having any issues with flow during recirculation?

I don't want to go to a RIMS tube, but that seems like an option here. Any other thoughts?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)