Apart from figuring out a permanent home for the control panel that will allow to be at workable height when brewing but stow away neatly, the brewstand is done!

Three coats of stain and three coats of polyurethane

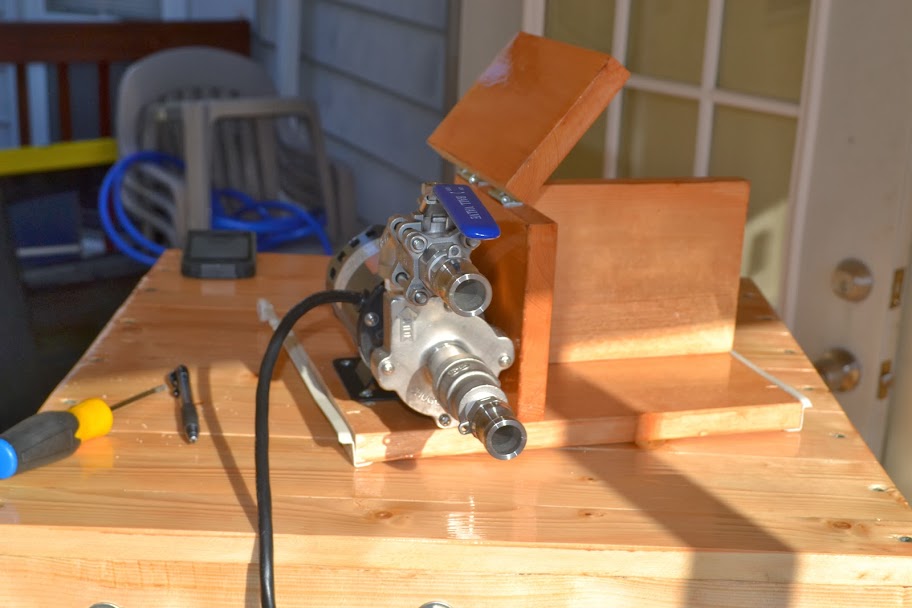

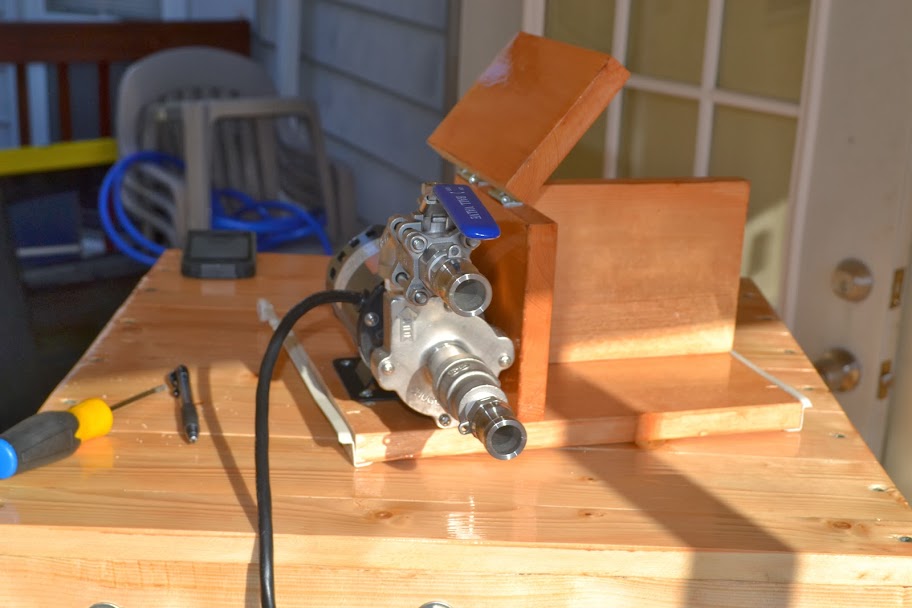

The pump / plate chiller sliding platfrom with hinged ceiling to protect the pump motor from liquid

Hinged so that the pump can be removed if needed

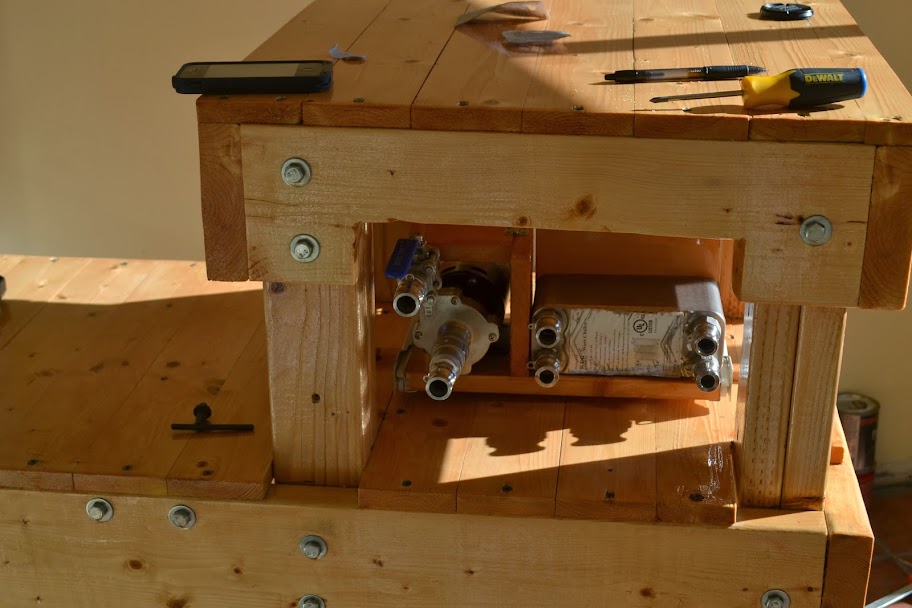

Pump / plate chiller retracted for storage

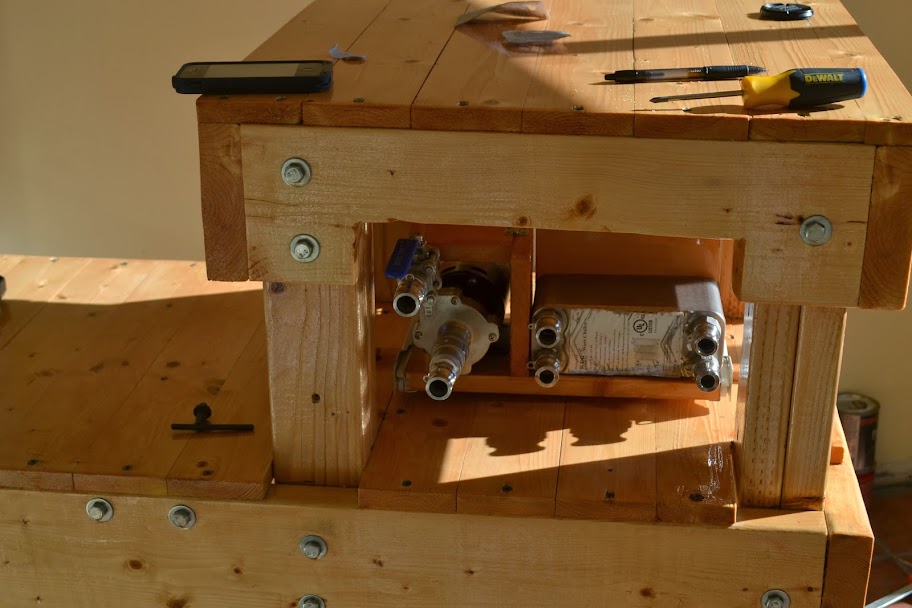

Pump / plate chiller extended for use

Brewstand in its storage spot next to the kegerator

I am hoping to do my first brew on this system in the next few weeks!!!

Three coats of stain and three coats of polyurethane

The pump / plate chiller sliding platfrom with hinged ceiling to protect the pump motor from liquid

Hinged so that the pump can be removed if needed

Pump / plate chiller retracted for storage

Pump / plate chiller extended for use

Brewstand in its storage spot next to the kegerator

I am hoping to do my first brew on this system in the next few weeks!!!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)