I never cold-crash that low (usually around 40), but I still get crazy condensation, even with replacing the stock tubing with thicker-walled tubing. Wish there was a work-around for this...

Ahh, USplastics, I used to use them all the time when I was building water cooled PCs.

Thank you for the information, I'll get those parts in and should be good.

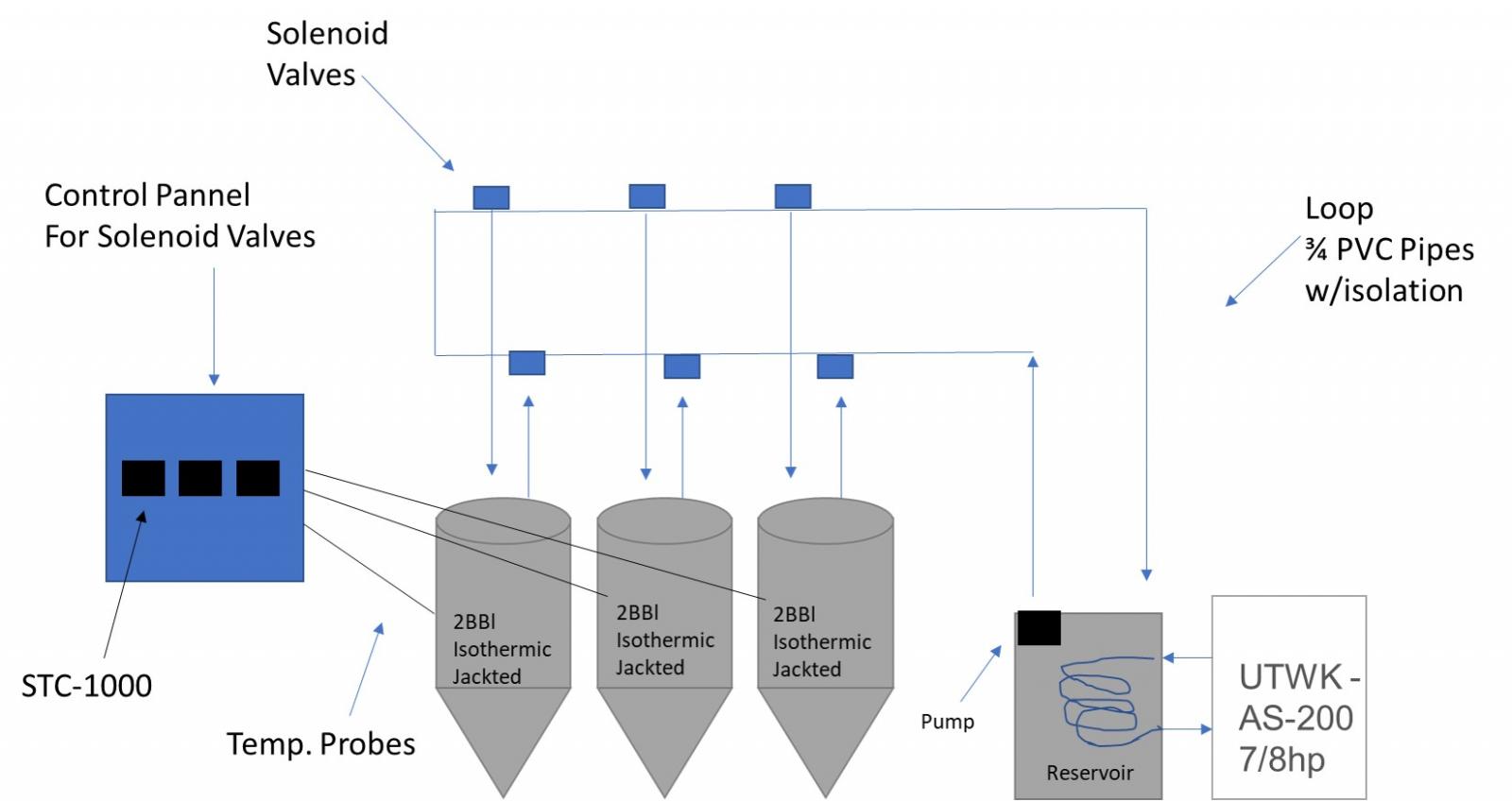

As for the condensation, yes, it's a bit of a pain, I could insulate the lines, I do have some insulation left, perhaps I'll try and see.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)