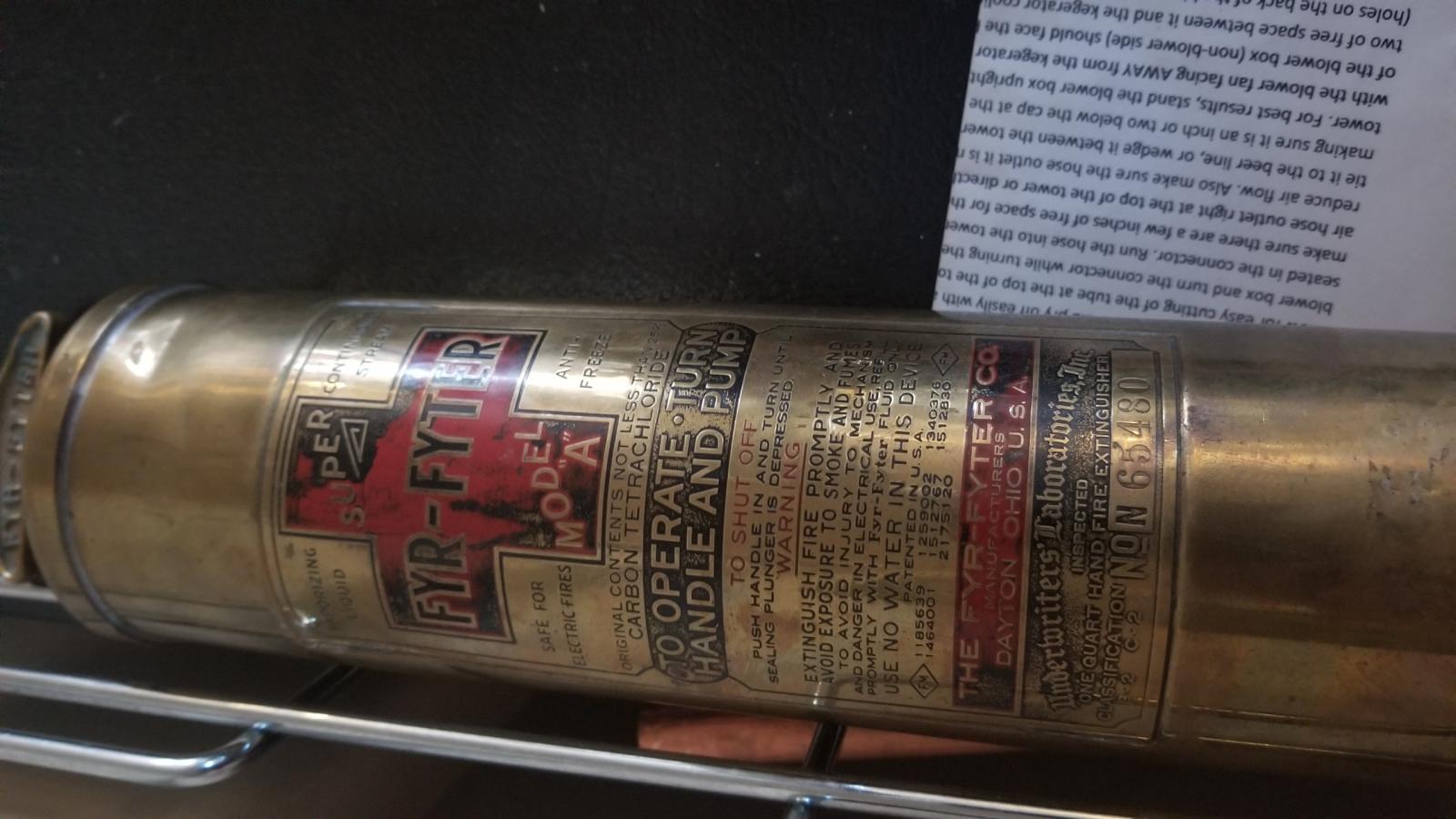

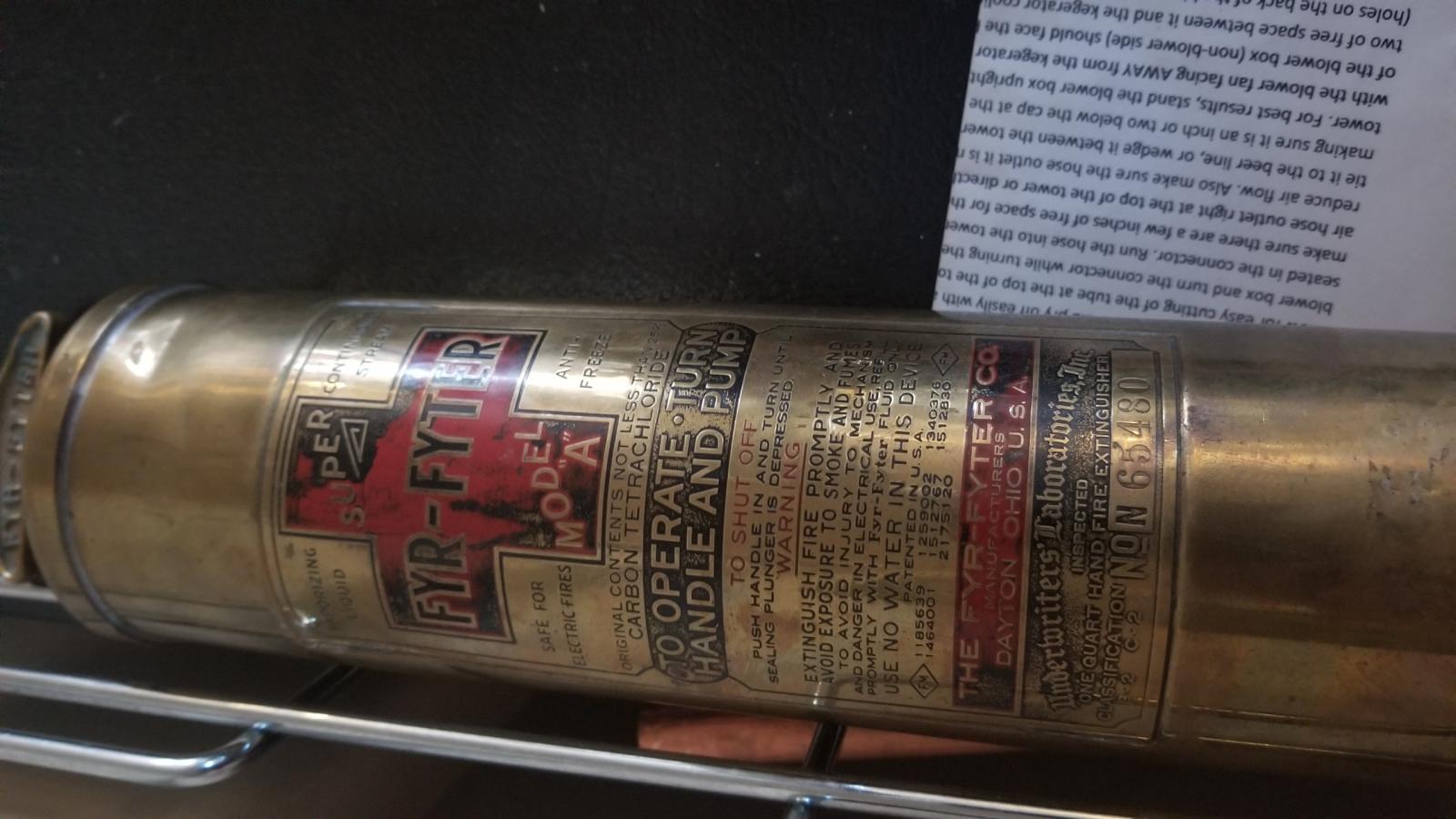

I just finished this beer tower this weekend. I started with a Antique FYR-FYTER Fire Extinguisher and thought I would share. I am pretty handy but all the tools I had in my garage and located the fire extinguisher locally. This was dome mostly to be different and also to add a second tap to my Kegorator.

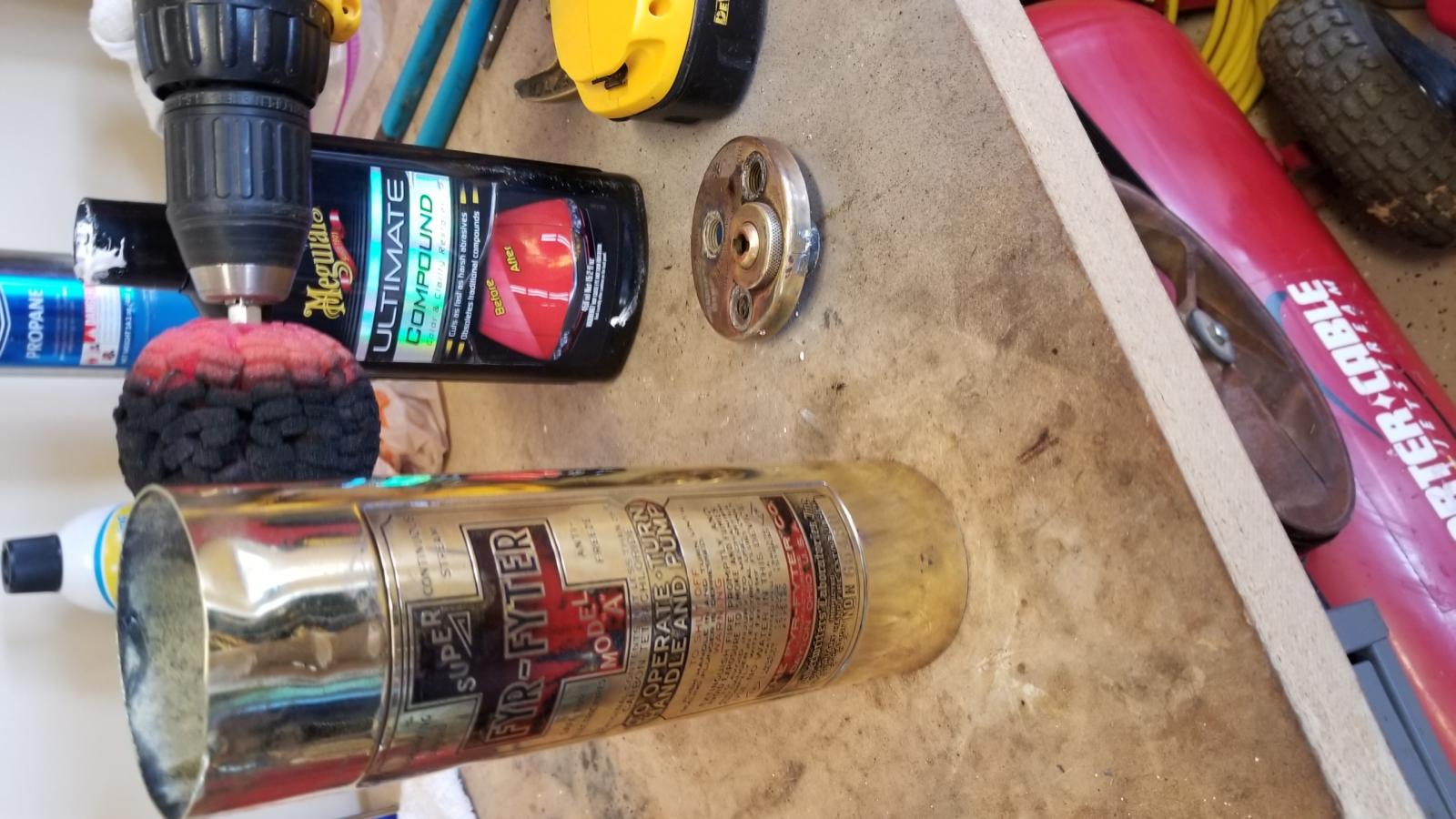

>First I started with a 4" grinder and a cut off wheel (I do not have a cut off saw so I free handed the cut) and cut off the bottom of the extinguisher you can see in the pictures the crap that came out

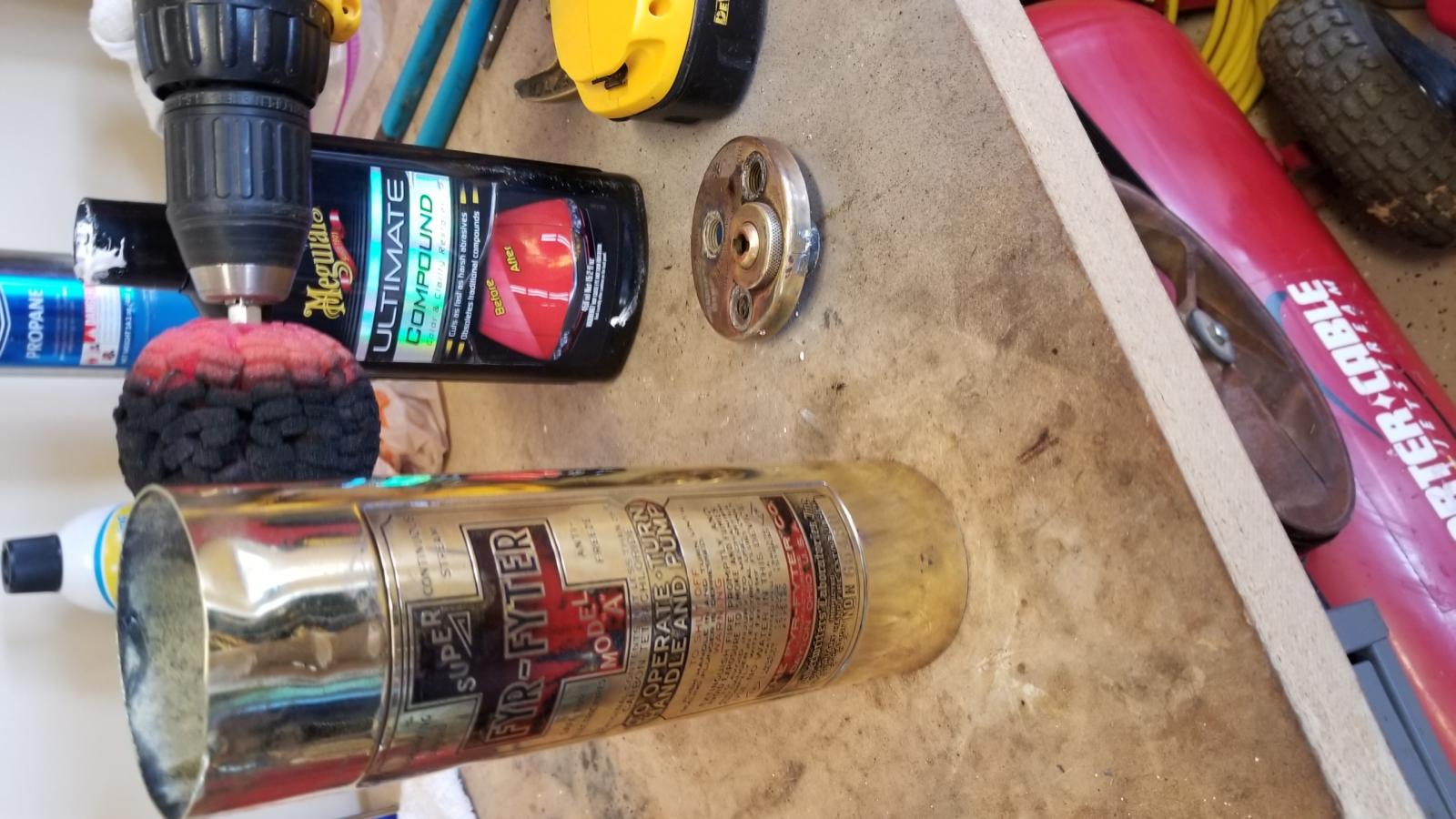

>Next I tried to un-solder the top but I could not get the whole thing hot enough with a propane torch.

>So I cut it just below the solder joint

>I then cut out all the guts of the unit

>Then un-soldered the top from the piece that was still left inside the top, came out pretty easy now

>I then used rubbing compound and a buffing wheel for car rims to polish the brass (cleaned up quiet nicely I must say). I washed the inside and out to make sure I get the crap out of the inside.

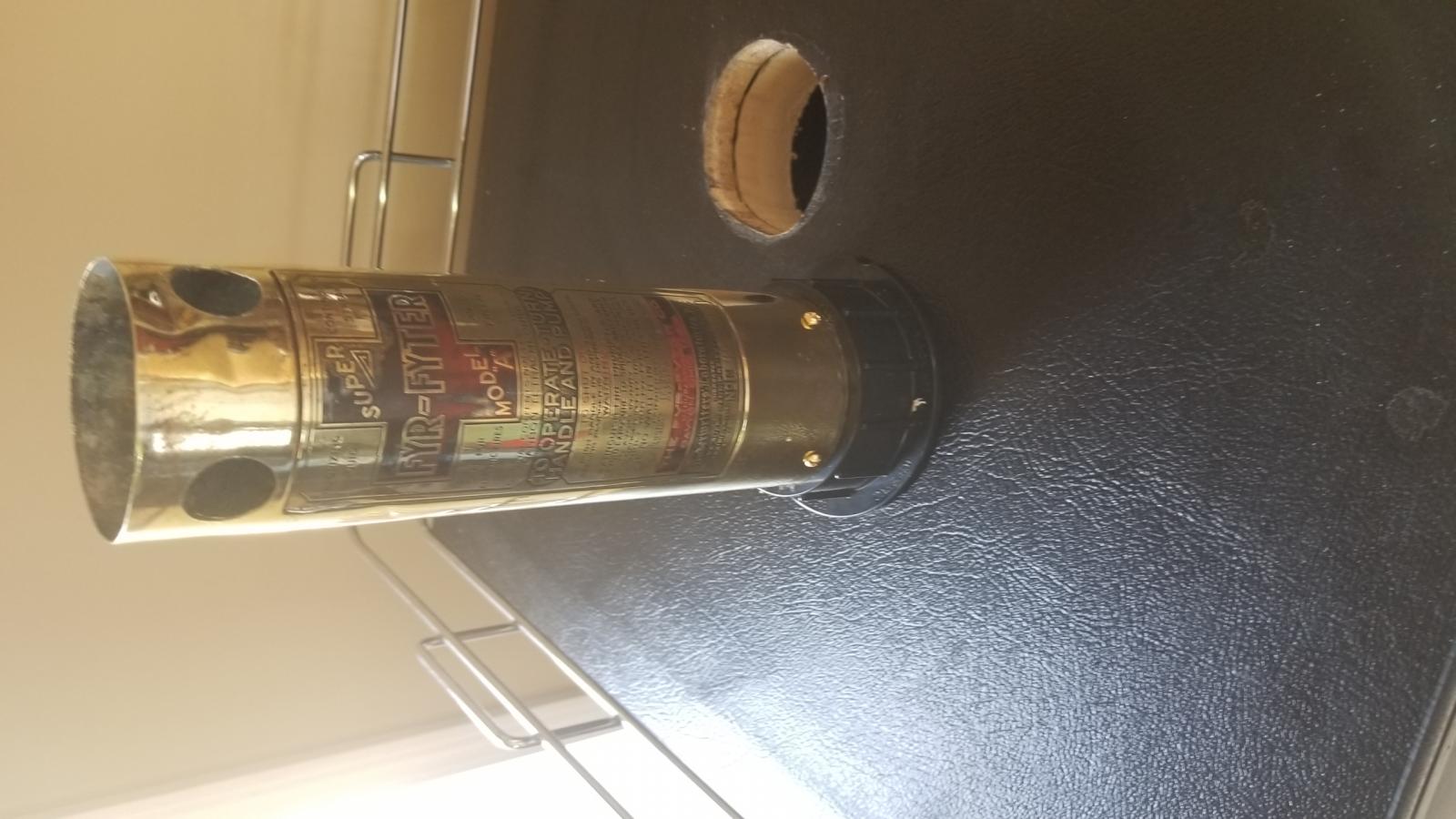

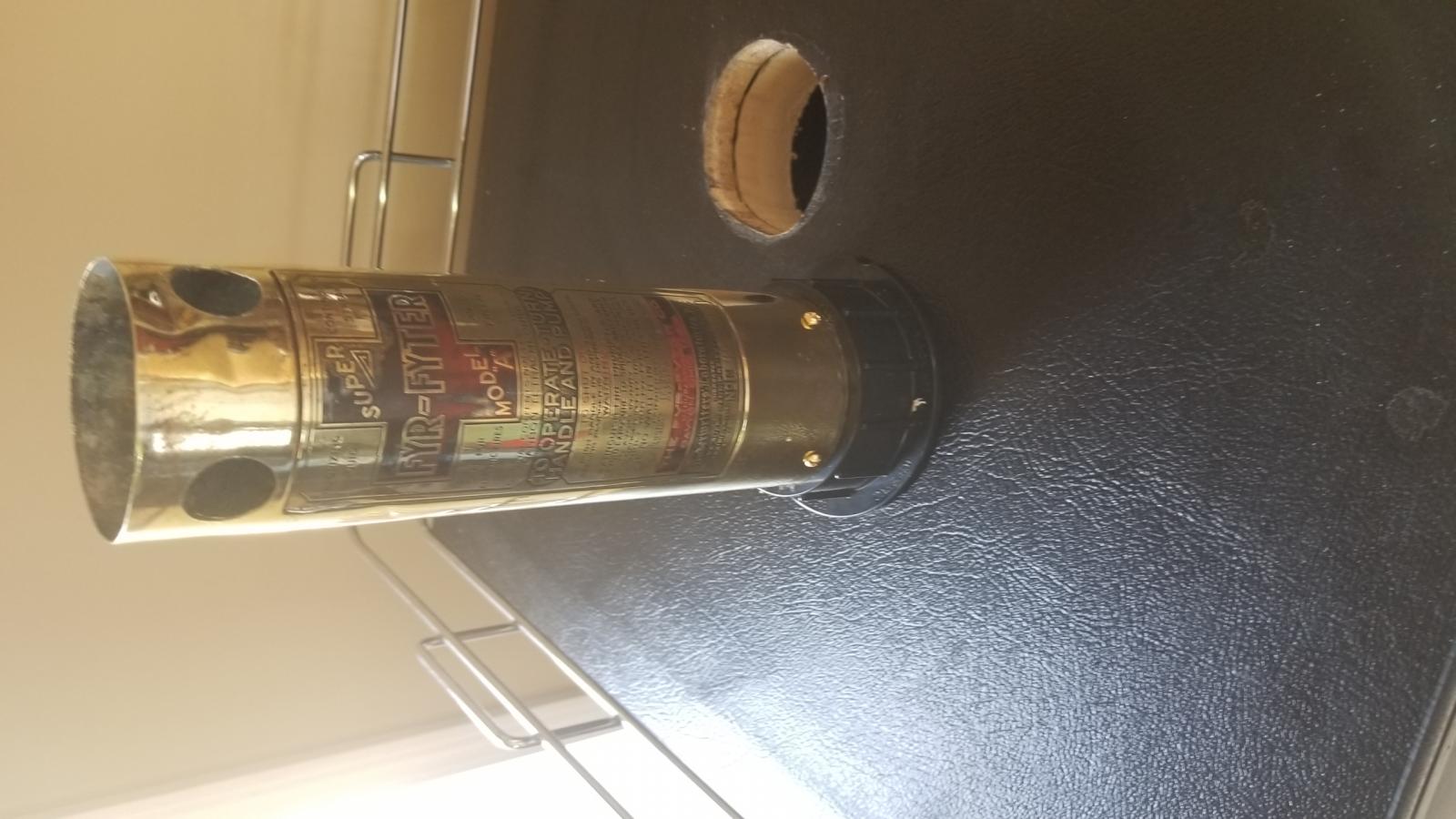

>Drilled out the 2 holes for the faucets (I used a 22MM hole saw and needed to do a little filing to make it fit but that was the closest hole saw I had)

>For the base I went to Home Depot and bought a PVC 2" shower drain turned up side down and fit with in about a 16th of an inch, also comes with a gasket

>Got some Brass flat head screws and nuts and fastened the PVC base to the cylinder

>Completed the based with some clear silicone caulk for a nice finish

>jig sawed out the hold in the top of the fridg to the size of the base

>Used 4 black headed screws I had on hand already

>Plumed the hoses to the installed faucets (I also added 1/2" copper pipe over the hoses and zip tied the bottom so they stay in place

>Pressured everything up and had a beer! Life is good!

See pictures attached

>First I started with a 4" grinder and a cut off wheel (I do not have a cut off saw so I free handed the cut) and cut off the bottom of the extinguisher you can see in the pictures the crap that came out

>Next I tried to un-solder the top but I could not get the whole thing hot enough with a propane torch.

>So I cut it just below the solder joint

>I then cut out all the guts of the unit

>Then un-soldered the top from the piece that was still left inside the top, came out pretty easy now

>I then used rubbing compound and a buffing wheel for car rims to polish the brass (cleaned up quiet nicely I must say). I washed the inside and out to make sure I get the crap out of the inside.

>Drilled out the 2 holes for the faucets (I used a 22MM hole saw and needed to do a little filing to make it fit but that was the closest hole saw I had)

>For the base I went to Home Depot and bought a PVC 2" shower drain turned up side down and fit with in about a 16th of an inch, also comes with a gasket

>Got some Brass flat head screws and nuts and fastened the PVC base to the cylinder

>Completed the based with some clear silicone caulk for a nice finish

>jig sawed out the hold in the top of the fridg to the size of the base

>Used 4 black headed screws I had on hand already

>Plumed the hoses to the installed faucets (I also added 1/2" copper pipe over the hoses and zip tied the bottom so they stay in place

>Pressured everything up and had a beer! Life is good!

See pictures attached