mmanolis2001

Member

- Joined

- Dec 29, 2015

- Messages

- 5

- Reaction score

- 3

I have been wanting to get into home brewing for a couple years now but I always find an excuse not to start another hobby. I have watched hours of videos on YouTube over the last two years and even stashed empty bottles here and there for a time.

This year I received a Mr. Beer for a Christmas present and it got gears grinding again. I made my first batch with this kit on Saturday and I made some mistakes right off the bat.

I had a hard time bringing my batch of wart down to the 70 deg mark. It was a mess. I didnt read the instructions with the kit closely enough and boiled up to much water to mix the wart with. Then I poured this into the little fermenter and added not so cold water. The result was 2 gallons of wart sitting at 120 deg in the fermenter. It sat on my counter for 20 mins only dropping a few degs. Then I placed the whole thing in the freezer until the temp was safe to pitch the yeast. Good thing that little fermenter is small.

Who knows how this batch will come out. It was the Diablo IPA that came with the kit. Now its infused with freezer burn and whatever else made it into the batch while sitting on the counter top at 120 deg. I guess I will bottle it if it smells good and there is no white fuzzy stuff on top after the ferment.

So that disaster got me thinking about modifying things, adding chillers etc

Instead of engineering something to use with the Mr Beer I decided to upgrade to a better beginner kit. I think Mr Beer is going to be a small batch bottling container after its first ferment. Poor little fellow I pushed him to the side before the batch started fermenting.

I found a local Home brewing store right up the street from me and picked up some goodies on the way home today.

I also stopped at Home Depot for some more supplies. Now I have the following sitting in my basement waiting for me to jump into.

Decided to make a pre chiller to go ahead of the immersion chiller. This will sit in a pot with Ice water. Hopefully this combination will bring the 3 to 4 gallon wart down to the pitching temp much quicker.

The Pre chiller is made with 10ft of 1/2" soft copper and the immersion chiller is 20ft of 1/2" soft copper. I tried not to mangle the bends but I did everything by hand without the use of a pipe bending tool. I did use a paint can to roll the copper into a coil. I found out that 1/2" soft copper is a pain in the tail to bend. I watched videos online where people were bending the uprights and elbows with little effort. I had the hardest time pulling the bottom coil thru without kinking and gave up trying to evenly space the uprights or put 90 deg bends on the ends. I just added 2 hose clamps to each connection and tightened the hell out of them.

Is 1/2" tubing the common copper size used in home made chillers or 3/8? I better hit the gym if everyone is bending 1/2 that easy by hand without kinking the tube.

I pressure tested the setup and had no leaks which is great and its compact enough to fit into the 5 Gallon kettle for storage. It will be a pain to drain both sets of coils though.

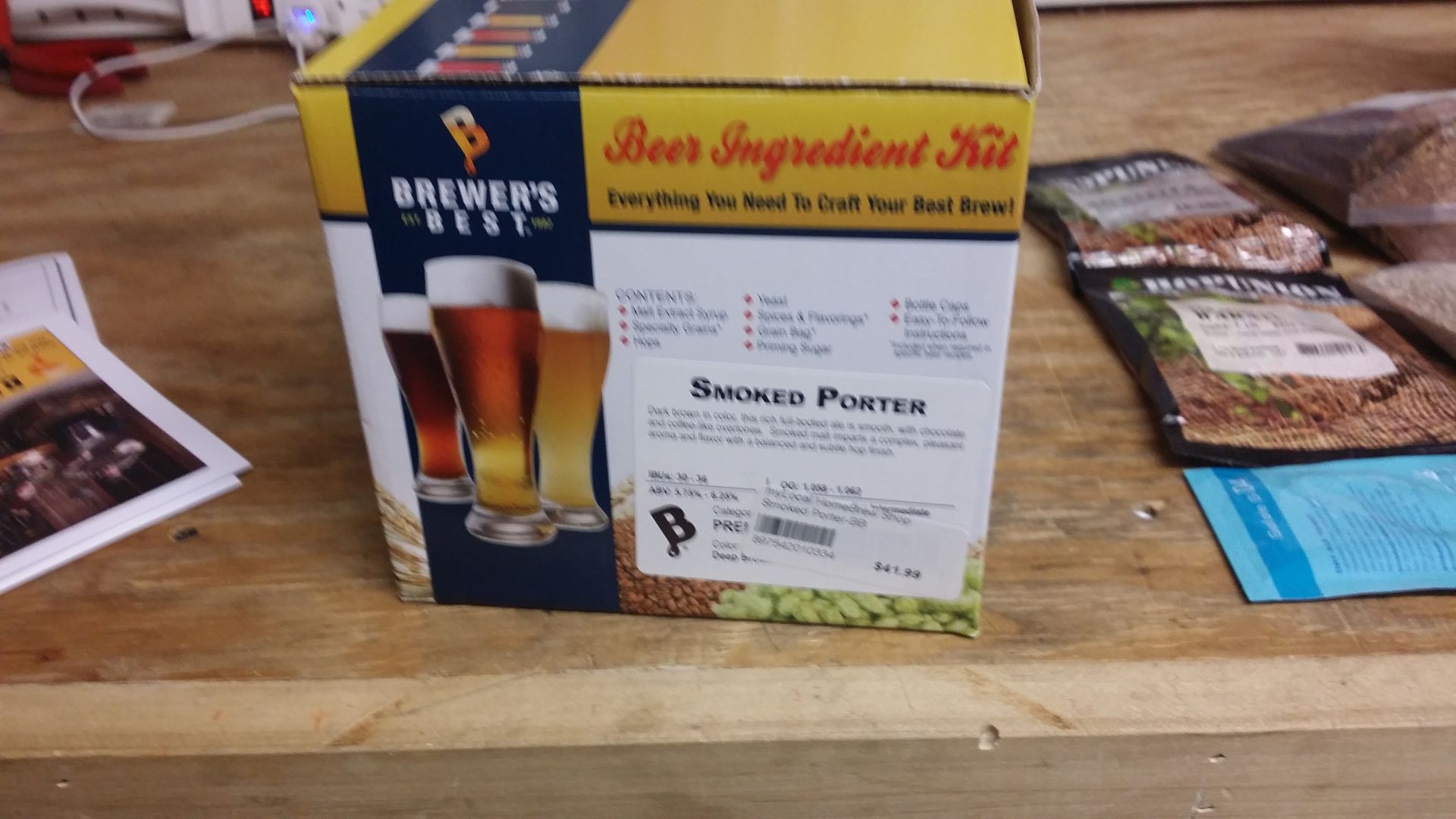

And these kits to get the pipeline started.

Now im kicking myself for throwing all those 22 oz Ranger bottles in the recycle bin over the years.

So now that Im jumping in head first I'm sure I will be bugging you all for tips over the foreseeable future.

Cheers

This year I received a Mr. Beer for a Christmas present and it got gears grinding again. I made my first batch with this kit on Saturday and I made some mistakes right off the bat.

I had a hard time bringing my batch of wart down to the 70 deg mark. It was a mess. I didnt read the instructions with the kit closely enough and boiled up to much water to mix the wart with. Then I poured this into the little fermenter and added not so cold water. The result was 2 gallons of wart sitting at 120 deg in the fermenter. It sat on my counter for 20 mins only dropping a few degs. Then I placed the whole thing in the freezer until the temp was safe to pitch the yeast. Good thing that little fermenter is small.

Who knows how this batch will come out. It was the Diablo IPA that came with the kit. Now its infused with freezer burn and whatever else made it into the batch while sitting on the counter top at 120 deg. I guess I will bottle it if it smells good and there is no white fuzzy stuff on top after the ferment.

So that disaster got me thinking about modifying things, adding chillers etc

Instead of engineering something to use with the Mr Beer I decided to upgrade to a better beginner kit. I think Mr Beer is going to be a small batch bottling container after its first ferment. Poor little fellow I pushed him to the side before the batch started fermenting.

I found a local Home brewing store right up the street from me and picked up some goodies on the way home today.

I also stopped at Home Depot for some more supplies. Now I have the following sitting in my basement waiting for me to jump into.

Decided to make a pre chiller to go ahead of the immersion chiller. This will sit in a pot with Ice water. Hopefully this combination will bring the 3 to 4 gallon wart down to the pitching temp much quicker.

The Pre chiller is made with 10ft of 1/2" soft copper and the immersion chiller is 20ft of 1/2" soft copper. I tried not to mangle the bends but I did everything by hand without the use of a pipe bending tool. I did use a paint can to roll the copper into a coil. I found out that 1/2" soft copper is a pain in the tail to bend. I watched videos online where people were bending the uprights and elbows with little effort. I had the hardest time pulling the bottom coil thru without kinking and gave up trying to evenly space the uprights or put 90 deg bends on the ends. I just added 2 hose clamps to each connection and tightened the hell out of them.

Is 1/2" tubing the common copper size used in home made chillers or 3/8? I better hit the gym if everyone is bending 1/2 that easy by hand without kinking the tube.

I pressure tested the setup and had no leaks which is great and its compact enough to fit into the 5 Gallon kettle for storage. It will be a pain to drain both sets of coils though.

And these kits to get the pipeline started.

Now im kicking myself for throwing all those 22 oz Ranger bottles in the recycle bin over the years.

So now that Im jumping in head first I'm sure I will be bugging you all for tips over the foreseeable future.

Cheers