hout17

Crush it REAL Good

@GoeHaarden I like your mill looks very nice. Also kudos on the hopper that's some great ingenuity!

Mine isn't as elegant as @Tom R but it was something I put together quickly with repurposed materials and it works rather well. Used an old pvc reducing coupler that was already torn on the side I cut off. A few pieces of scrap plywood and acrylic for the sides like Tom. Had a better bottle that was cracked so I cut the bottom off. 12 pounds filled it a little under half way, and I bet it'll easily hold 25lbs.

I plan to make a little cabinet/cart for it but for now I'm kind of digging the frankenstein feel of it to match the mill.

One thing to note, is that this mill is a beast and the rollers will NOT slip. That being said, if it gets packed your drill will torque hard with a tight gap. 0.025" scares me a little so I've jist stuck with 0.030 for now. I suggest securing the whole system. I hose clamped my drill to the plywood and it works.

@GoeHaarden On your top piece is there anything on the underside of to guide the grain to go between the rollers (so whole grain doesn’t fall between the rollers and outside walls)?

Mike

Appreciate the details. Have to laugh, I’m an engineer and spend too much time thinking of details. Your simplistic approach to this is excellent!Yeah, I just took a couple of pieces of sheet metal and cut them to size with some sheers and then bent them. They are screwed to the lower piece of 3/4" plywood. Very utilitarian.

For the mill top/hopper attachment. The bottom 3/4" plywood has large rectangle cut out in the middle leaving essentially only a ~3/4" ring for mounting. The second piece of 1/2" plywood on top only has a round hole cut out (~3" diameter, I didn't measure it just eyeballed). I did need to use 1/2" longer bolts for attaching to the actual mill.

Appreciate the details. Have to laugh, I’m an engineer and spend too much time thinking of details. Your simplistic approach to this is excellent!

mike

See the "Big Bang" episode when the group attempted to help Penny with her at home business? Way over thought... funny.Appreciate the details. Have to laugh, I’m an engineer and spend too much time thinking of details. Your simplistic approach to this is excellent!

mike

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

That's crazy. Sorry you're having issues with it. I don't think there is anything wrong with the mill, it's just straight from Mad Max and it runs on anger. Jokes aside, it was a little worrisome the first few times I ran it as those gears sound a little scary when they run.@GoeHaarden Can you give me the specs on that DeWalt drill (amps?)? What speed do you run it?

I just put my 3GT with my gear motor together today.

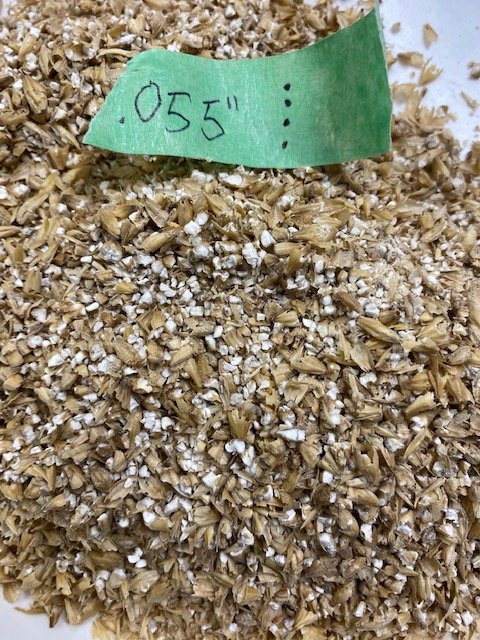

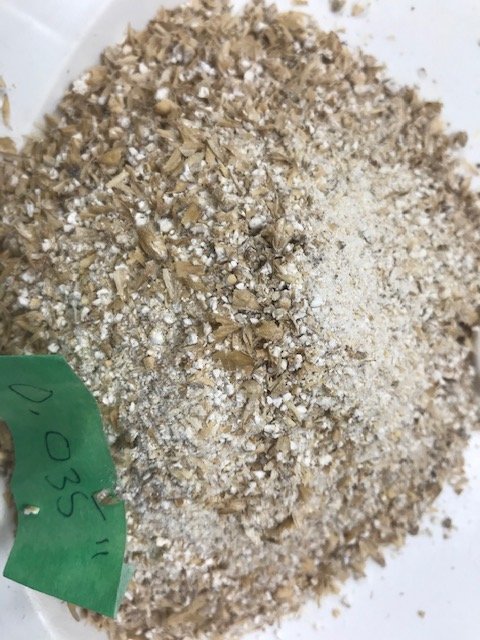

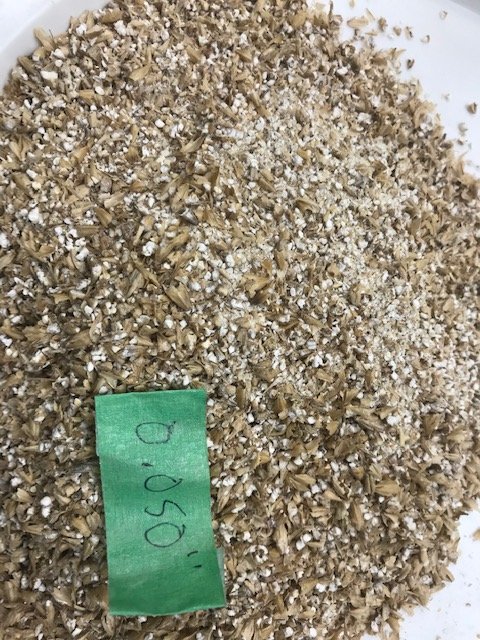

I'm a very unhappy guy right now. I ran my BarleyCrusher for about 17 years with a 1/2 HP 325 rpm gear motor. I could even start it with the hopper filled. Don at Crankandstein has been very helpful and told me my BC was running too fast and I should reduce the motor speed in half. So I bought a pair of pulleys and a belt and did just that. For the maiden run I set the gap at 0.035" and the motor stalled! It stalled at 0.045" and I think around 0.055" it ran. Then Don answered my call today and said to throttle the feed. I cut the area to about half. I could run 0.045" without a stall but no go below that.

OK - some motor questions. Do you think my motor is too weak for this mill (Don thinks so). I see a few use hand drills - can you tell me which model of drill and what amps. I have a DeWalt 115V 5.4Amp I can try but don't want to mess around if it too is too weak. I also have a 18V Makita cordless?

What about this 3-roller geared mill vs my 2 non-geared roller BC. Is there that big of a difference in torque to drive this new 3GT? Also, I'll attach some pics of my crushes. It looks to me that a 0.037" crush with my BC is about 0.045" on the 3GT.

I see @GoeHaarden is successfully running small gaps with a hand drill that looks like my DeWalt. Is it possible there is something wrong with the mill??

Thanks

Mike

I would not run a mill with that drill. It runs at 2800 rpm (!), way too fast, and by the time you slow it down to 150rpm, there's no torque left.

I would not run a mill with that drill. It runs at 2800 rpm (!), way too fast, and by the time you slow it down to 150rpm, there's no torque left.

The following model runs at 600 rpm, and is more similar in specs to the older Low Speed Heavy Duty model drill I've been using for over 8 years.

https://www.harborfreight.com/12-in-low-speed-spade-handle-drillmixer-56179.html

Haha. Yes, indeed. Those were the specs I was reading, too many pages open I suppose.

That's crazy. Sorry you're having issues with it. I don't think there is anything wrong with the mill, it's just straight from Mad Max and it runs on anger. Jokes aside, it was a little worrisome the first few times I ran it as those gears sound a little scary when they run.

I use a Dewalt DW235G that I've had boxed up for a few years and it pulls 7.8amps. Right now I try to throttle it manually, but I can tell when it starts to get bogged down and I need to bump the trigger a little. I try to run it on the lower side, but no way to know for sure at the moment (drill max rpm is 865). I need to get a router speed controller, but it mills so fast that doing it manually hasn't been an issue yet.

Honestly, I've thought about widening the gap a little and running it twice. I could probably mill my batch twice faster than most other mills can get through once. It takes under 90 seconds to get through.

I didn't even try to use any of my cordless drills with it. I should test my 20V cordless Dewalt to see if it'll even budge it.

Think I'll give the drill some thought. There is a HF couple miles from me and I bought that drill to use for mixing thinset for a big tile job in our bathroom. It was strange but it would loose variable speed control and only run on high when it was warmed up. I exchanged it and the second one did the same thing. Guess I could try one again - they actually have a great return policy.

When the 3GT would run on my gear motor it would really gulp the grain even at 160 rpm. Reminds me of a positive displacement pump - what you feed it must go through since all rollers are geared together. Other pumps have leakage so they don't get overloaded - like my old Barley Crusher.

That old gear motor I have is only rated at about 3.4 amps and 4.9 ft-lbs (my 18v makita drill is 42 ft-lbs).

Oh well, I can put this back on my BC and sell it as a motorized mill now.

Did you try the Makita on it?

Did you try the Makita on it?

SUCCESS!!!

Put my Makita cordless on it and it will run 0.025" even with the hopper filled from a dead stop! But, @GoeHaarden is correct the mill-drill-base are starting to hop around badly.

So glad - thanks for all the help. My setup will be much simpler now with a removable drill.

Thanks

Mike

I love this new mill!

Plus, if I were to use 0.025" gap with this mill all the time it would need a stronger base than plywood

Still like mine and can highly recommend it. I haven’t had any issues with it. Time will tell how long the knurls on the rollers will last, but the geared rollers should alleviate any knurl wearing issues@GoeHaarden and others in this thread who have the 3GT......do you still like it? Any issues or regrets?

Pretty sure I'm going to order one but just checking in.

Thanks!

I still love mine. No regrets here. Finally broke down and got an Ale Works motor for it last year and the whole setup is great.@GoeHaarden and others in this thread who have the 3GT......do you still like it? Any issues or regrets?

Pretty sure I'm going to order one but just checking in.

Thanks!