I've been brewing almost 10 years (all but the first 2 brews have been all grain). For the last 6 years I've been brewing on a 3 Vessel Gas Herms system utilizing 2 Keggles and a large Igloo cooler. I'd like to convert this to an all electric system. During a remodel I've installed a 240V/50A line (6-2 w/ ground) direct to my workshop with the intention of converting my current system to electric (Will make winter brewing more tolerable to say the least). While my hopes are to eventually become more and more automated with a BruControl setup, I am choosing to start out with the CraftBeerPi setup because it makes the most sense for me right now. This being said, I could use plenty of guidance. So please be patient with me as I work through this conversion.

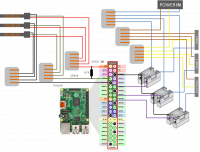

This is the diagram for connecting straight to the Pi's I/O's.

#1 - Is a Spa panel absolutely necessary? Wouldn't it be less complicated to just swap the 50A Breaker with a 50A GFCI breaker at the subpanel?

#2 - I plan on using a 5500 Watt element along the lines of:

https://www.amazon.com/Rheem-SP10869PH-5500-watt-Resistored-Stainless/dp/B009AX2VAK

This being the case should my SSR be rated at 50A or should I use a 30A SSR since a 5500 Watt element is using less than 25A at 240V?

https://www.amazon.com/Fotek-Solid-Module-24-480VAC-SSR-50DA/dp/B08DF76YWD

I know I've read to avoid this brand specifically, but it was the quickest to show up on Amazon when I made a search for 50A breakers.

#3 - My current pump is 120V. What's the best way to wire in a 120V outlet?

#4 - What gauge wire should I use?

#5 - To those who have build a CBP setup, what do you know now, that you wish you would've known before starting?

This is the diagram for connecting straight to the Pi's I/O's.

#1 - Is a Spa panel absolutely necessary? Wouldn't it be less complicated to just swap the 50A Breaker with a 50A GFCI breaker at the subpanel?

#2 - I plan on using a 5500 Watt element along the lines of:

https://www.amazon.com/Rheem-SP10869PH-5500-watt-Resistored-Stainless/dp/B009AX2VAK

This being the case should my SSR be rated at 50A or should I use a 30A SSR since a 5500 Watt element is using less than 25A at 240V?

https://www.amazon.com/Fotek-Solid-Module-24-480VAC-SSR-50DA/dp/B08DF76YWD

I know I've read to avoid this brand specifically, but it was the quickest to show up on Amazon when I made a search for 50A breakers.

#3 - My current pump is 120V. What's the best way to wire in a 120V outlet?

#4 - What gauge wire should I use?

#5 - To those who have build a CBP setup, what do you know now, that you wish you would've known before starting?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)