- Joined

- May 6, 2025

- Messages

- 286

- Reaction score

- 222

Good morning all,

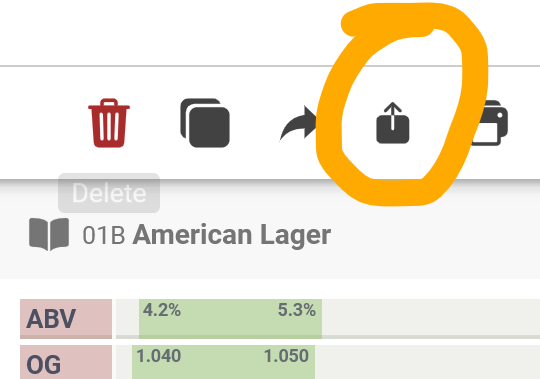

Today I will be brewing with Brewfather for first time.

I'd like to see if others can view a Brewfather profile from the link

In particular, I'd like comments on the ratio of strike water to sparge water. It's 15 liters to 10 liters, which seems like a lot to me.

https://web.brewfather.app/tabs/recipes/recipe/DGgfAKFV6GQI0HzjVu8X1sz74gAR1l

Today I will be brewing with Brewfather for first time.

I'd like to see if others can view a Brewfather profile from the link

In particular, I'd like comments on the ratio of strike water to sparge water. It's 15 liters to 10 liters, which seems like a lot to me.

https://web.brewfather.app/tabs/recipes/recipe/DGgfAKFV6GQI0HzjVu8X1sz74gAR1l

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)