Just for fun, let's go back to fundamentals. It is a cool drizzly morning here in Oz and the apples aren't quite ripe yet, so I might as well spend some time inside and throw in my two cent's worth.

To carbonate, you need enough sugar in the sealed bottle for residual yeast to eat it up and convert it to C02 and alcohol. Fermenting 2 gravity points will produce about 1 volume of C02, so for normal carbonation at 2 - 3 volumes you need to start with something like SG1.005 and finish with SG1.000. SG 1.005 is about 10g of sugar per litre, which is what the conventional wisdom (or at least Andrew Lea) says you need.

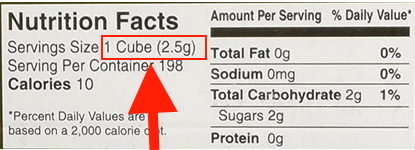

This translates to 3.3g per per 330ml (12 oz) bottle. The trick then, is to add enough sugar to suit your bottle or level of carbonation that you are after. Hey presto!... Some "popular" carbonation drops are 3.3g which is just right for a 330ml (12 oz) bottle, but if you are using different bottles you need different quantities of drops.

I actually prime in my bottling bucket, using apple juice or a sugar syrup (it mixes in easily and evenly), and measure the resulting SG rather than relying on quantity. Sugar will mix in near boiling water at a ratio of about 3:1 but I usually do 2:1 and also get the advantage that the hot water sanitises the sugar, so it doesn't add any unwanted nasties.

So, if you want to prime bottles, my suggestion is to make up a sugar syrup and add that via a small syringe. To make life really easy a 1:1 syrup means that you are adding 1g of sugar per ml of syrup, so 3 - 4 ml (or about 2/3 teaspoon) per 330ml (12oz) bottle does the job.

Anyhow it works for me. Have fun!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)