garrettryder

Member

- Joined

- Jul 4, 2012

- Messages

- 5

- Reaction score

- 0

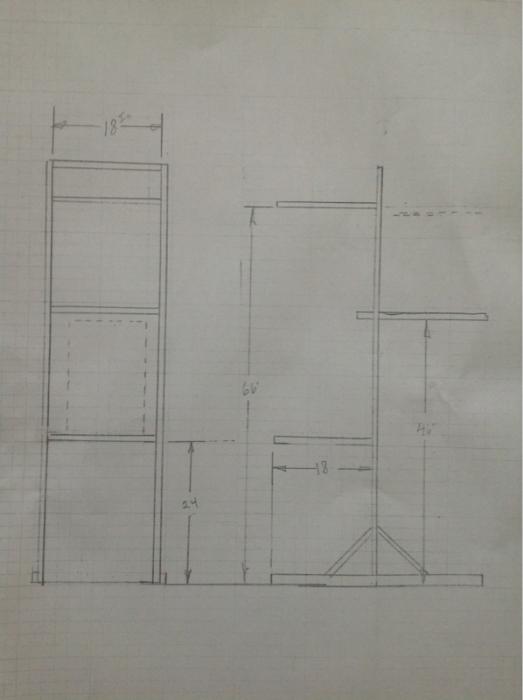

Hey guys, i started brewing little over year ago, and I'm making the jump to all grain. I decided I want to make my own three-tier gravity fed brew structure, I have some rough ideas already but I want some input before I start fabricating. Currently I have 60 feet of 1 1/2 square tube 13 gauge steel, I'm planning on installing a burner on the top tier and the bottom tier and use a cooler for my mash tun in the center tier. I speced out mega pots from Northern Brewer for my height and width spec (15 gallon). I do not see myself brewing 15 gallons in one batch however, I would like to have the capacity to do a high gravity 10 gallon batch. I would love to have your input your ideas for any modifications I may need to make, before i start welding this structure up. Here's a rough sketch of my structure with a front view, and a side view. Thank you for your input it's greatly appreciated! Garrett

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)