The boiling point at that altitude actually does change that much, that's why I mentioned it. Check this out:

Boiling Point at Altitude Calculator

Every time I've reported an issue with Kegland they dismiss me and say that "if that was true, why haven't they heard from others reporting the same problem?" The problem is that most likely most users have never bothered checking the accuracy of their equipment, or just don't bother to report it and work around it. I also work around it but feel its the responsible thing to do to always let the manufactuer know if there are issues so that they can correct it. I don't think Kegland really cares, as they now don't respond to me at all.

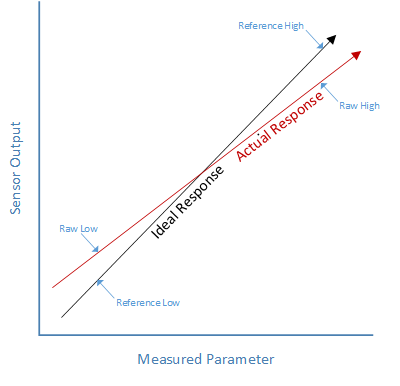

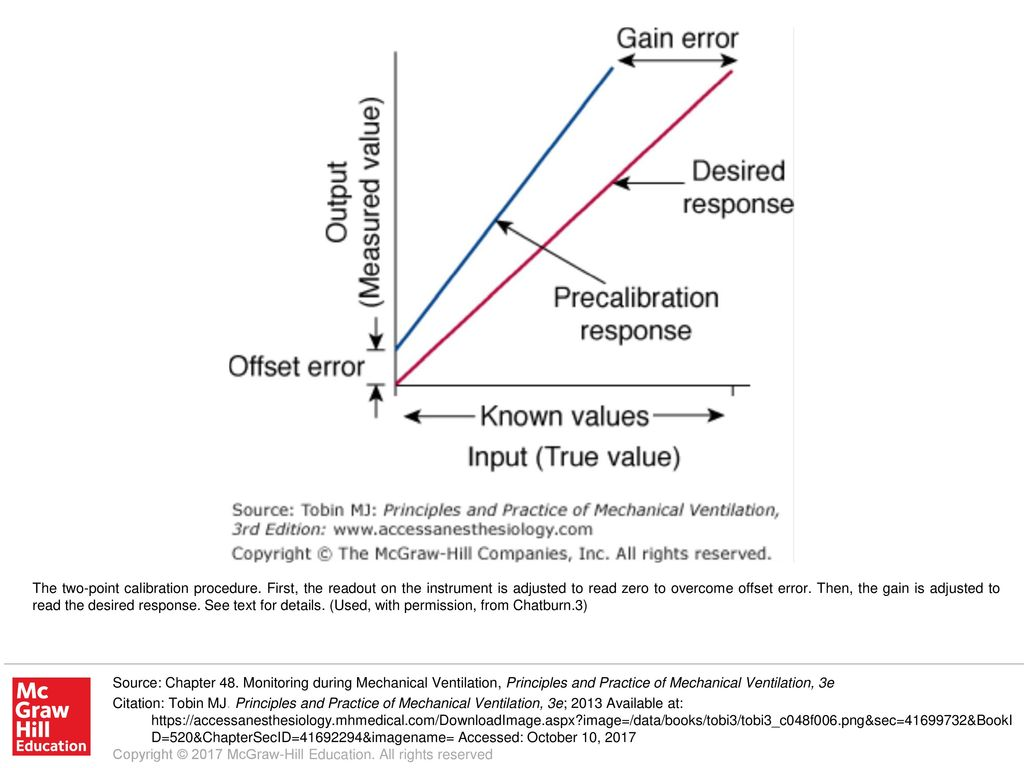

I've pointed out two programming errors and they refuse to admit it. I was a programmer for over 20 years and know that no programmer is perfect. I also do all my own brewing calculations (I don't use a Brewing Program) so know a little about programming. If one does a two-step calibration and enters both the freezing and boiling points accurately, the calibration program should be able to easily divide this by 100 (for Metric) or 180 (for Imperial) for the intermediate points. There is no way that an intermediate temperature should then be off by 3 degrees Fahrenheit as myself has found as well as one other person! At most one might expect a half degree or so. That other person's Brewziall was also 7 F out with the Factory calibrations as was mine and at least one other had the same issue.

Also, their RAPT app contains a programming error. If one sets the Brewzilla to Imperial, and checks the RAPT app, it will show the temperature in Metric - with an "F" for Imperial!! Sometimes it briefly shows the Imperial temperature but then quickly reverts to Metric. This should be a simple programming error to correct, yet the Kegland representative thanks me for bringing this to their attention by completely ignoring my email and refusing to respond.

It would be so easy to do the dilgent thing and check the program and see if there was indeed an error. There's absolutely no question that the RAPT app does contain an error. Anyone can easily check that but Kegland refuses to even so that. And logically, the calibration program HAS to contain an error. Dividing the two ranges and dividing by either 100 or 180 is a straight-forward mathematical exercise, so it should come out fairly accurate, not 3 degrees out! That simple check would elevate the credibility of the Brewzilla a lot. But they ignore single reports of issues, even if that person tells them that several others have had the same issue.

In fact, when I did the calibration for the boiling point, the Brewzilla read 219.2 F!!!! The freezing point was 26.8 F. There's no way those can be right!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)