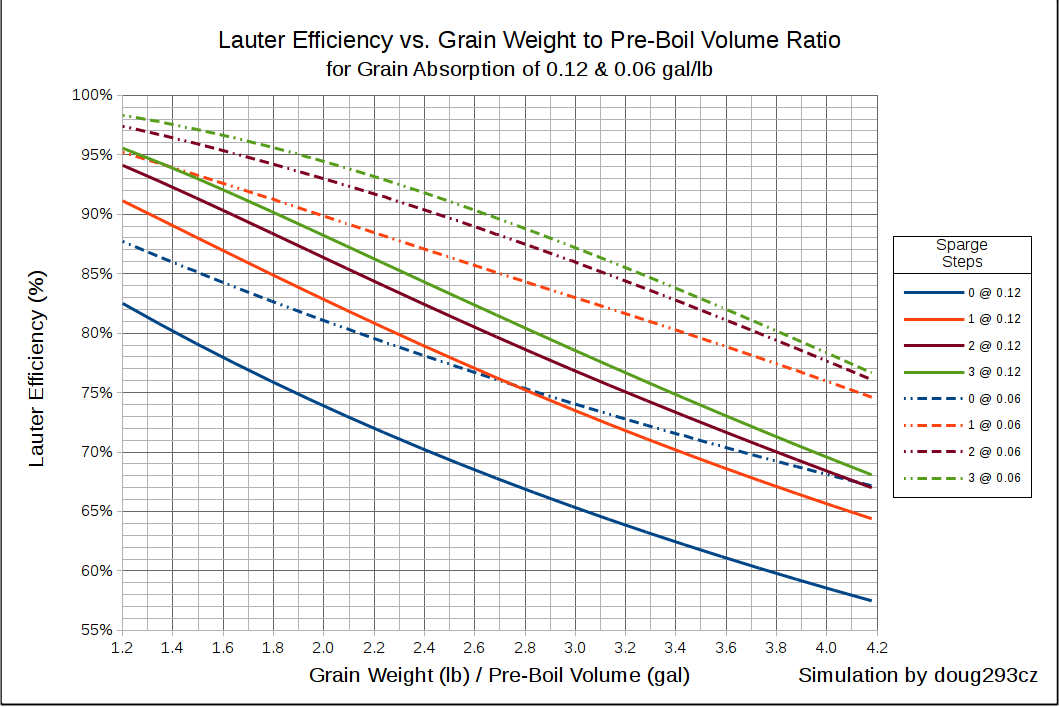

Efficiency (specifically lauter efficiency) drops as the amount of grain increases for the same pre-boil volume. This is because the more grain you have the more wort (and sugar) gets left in the spent grain mass. Sparging increases lauter efficiency vs. not sparging, but will not make up for the increased grain absorption.

Here's a chart that shows this effect for batch and no-sparge processes. Fly sparging (if done well) will have a few percentage points higher lauter efficiency than a triple batch sparge at 0.12 gal/lb absorption rate.

Mash efficiency is conversion efficiency times lauter efficiency. You can improve lauter efficiency by doing more aggressive sparging, but you will always have losses during lautering, as shown above. If your conversion efficiency is not close to 100%, then your mash efficiency will be reduced.

In order to diagnose efficiency issues, you need to know if your conversion efficiency is lower than it should be, or if you lautering process is giving lower than the theoretical best given by the chart.

You can calculate conversion efficiency just by knowing the grain total weight, the weighted average extract potential for the grain bill, the strike water volume, and the SG of the wort in the MLT at the end of the mash. I give the

details here.

Then you calculate your lauter efficiency by dividing the mash efficiency by the conversion efficiency.

Brewhouse efficiency is just mash efficiency * volume in fermenter / post-boil volume. If your mash efficiency is already high, then you can increase your brewhouse efficiency by leaving less wort behind in the BK while transferring to the fermenter.

You can predict your mash efficiency for a given recipe by using

my spreadsheet.

If you want other people to help you diagnose your efficiency issues, you should collect and report the following values:

- Grain bill weight, and weighted average extract potential

- Strike water volume, and temp at which volume was measured

- SG of wort in MLT at end of mash

- Pre-boil volume, and temp at which volume was measured

- Pre-boil SG (temp corrected)

- Post-boil volume, and temp at which volume was measured

- Post -boil SG (temp corrected) - i.e. the OG

- Volume to the fermenter, and temp at which volume was measured

Accuracy of the above data is critical, as the accuracy of the calculated values can be no better than the accuracy of the input data.

Since you didn't provide any volume measurements, there is nothing we can say about your efficiencies.

Brew on

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)