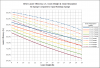

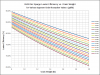

Here's the efficiency story for no sparge BIAB. The data is for 100% conversion and 6.75 gal pre-boil volume (corrected to 68°F). Strike volume is adjusted for grain absorption to get a constant pre-boil volume. Grains are assumed to have 80% by weight conversion potential on a dry basis, and 4% moisture ("as is" conversion potential of 76.8%)

Grain absorption is affected by how long you drain and/or how well you squeeze. If your conversion percentage and your grain absorption (gal/lb) are consistent, then your efficiency will be consistent and depend only on your grain bill.

Brew on

Grain absorption is affected by how long you drain and/or how well you squeeze. If your conversion percentage and your grain absorption (gal/lb) are consistent, then your efficiency will be consistent and depend only on your grain bill.

Brew on

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)