Well, yesterday was a very good day.

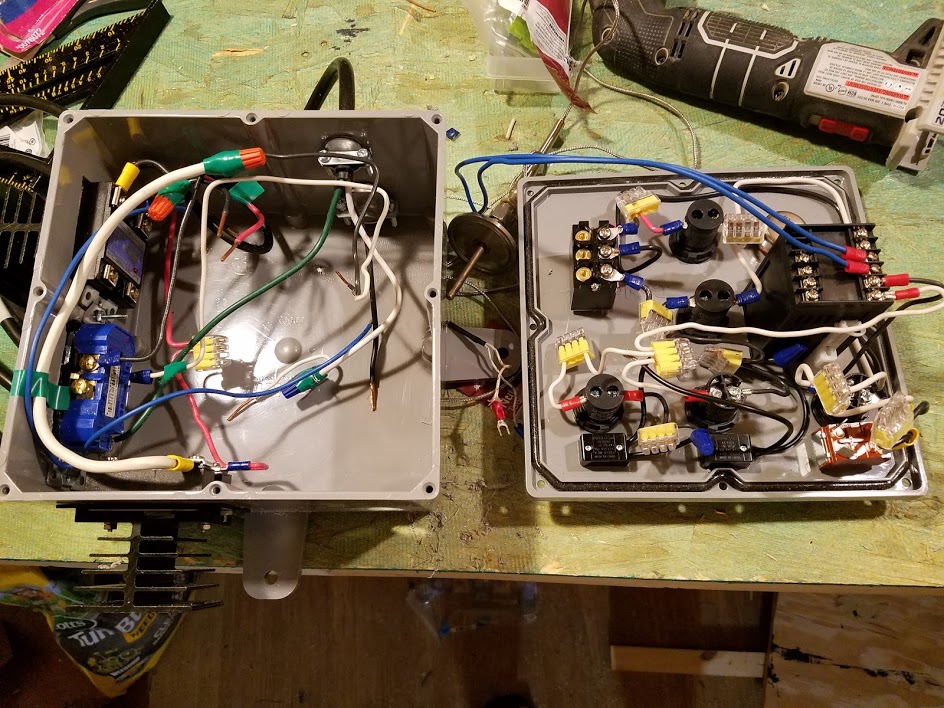

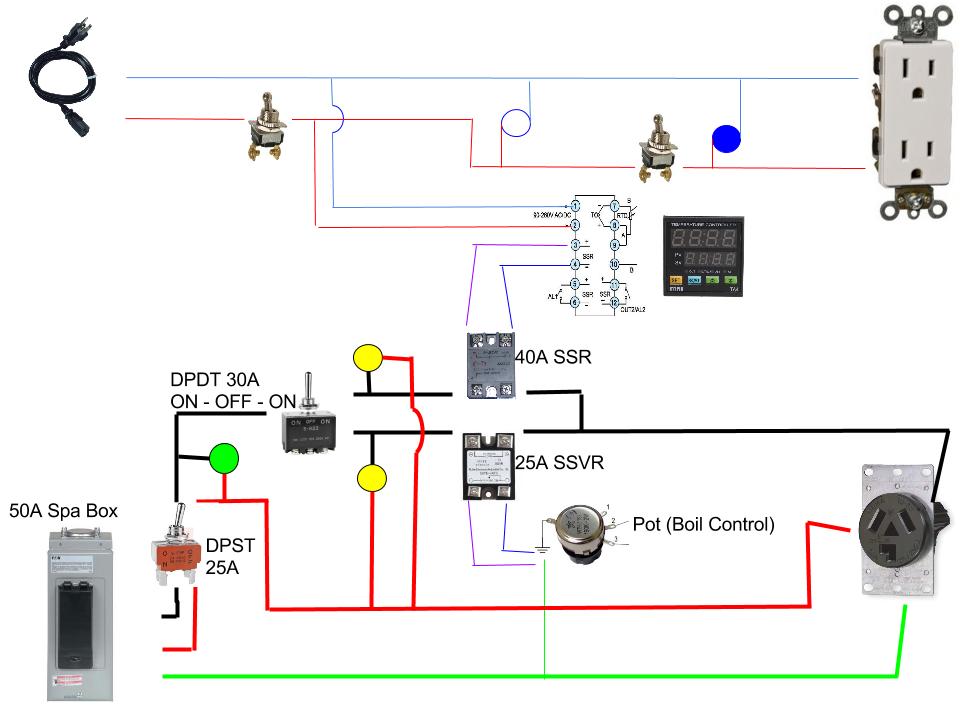

After work I was able to get all of the big bits installed and the electronics tested. Getting the controller plugged in and running has relieved a huge amount of anxiety. It was the only part of this whole thing that I wasn't 100% confident in my ability to do myself. As should be clear by now, I am by no means an expert with electricity, and have never worked with 240V before. Definitely an anxious moment checking the final connections, putting on the lid, and hitting the switch for the first time. That said, it looks like my research and ambition paid off, and it all appears to work (water test pending). There is one issue with the lights that may not be a bad thing after all.

Remaining Tasks:

- Jaded CFC comes in tomorrow. I'll mount that to the stand and run permanent water to it

- Paint stand and drill drain

- Reinforce stand legs with frame

- Finalize pump orientation and placement, mount

- Plumb beer route for pump/CFC

- Mount vent hood and fan

- Clean piles of wire pigtails, sawdust, switches and spades, tools, brewing equipment that are basically covering my house.

- BREW.

I think all of this (except brewing) can be knocked out in basically a single day.

Here are a couple shots of the nearly finished product, though it's tough to get glamour shots in my seriously unglamourous basement at midnight.

:rockin::fro:

:rockin::fro: :fro:

:fro:

:rockin::fro:

:rockin::fro: :fro:

:fro: