I posted on beer thirty's

thread about his new system but its short on details. we would like to make it as automated as possible, with the exception being to add grains and hops.

How did/would you connect your system to be automated Cape Brewing?

I would simply need a computer to run all of the switches, put in some sort of flowmeters for volume control and then build something to do my hop additions. Everything else is done.

A motorized mash rake would also be a good-to-have. I have the motor but never bothered to build a rake or hook it up

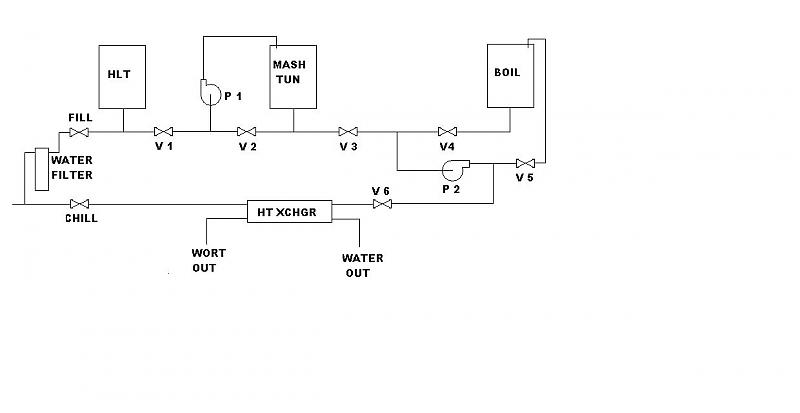

I quick connect a hose to one end that runs through a water filter and then it hits the first solenoid.

- fill HLT - a switch

- fill BK - a switch

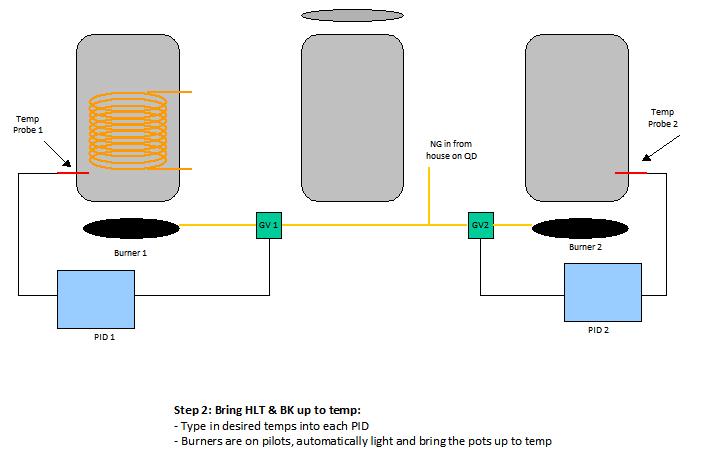

- bring HLT up to temp - type in temp on PID

- bring BK up to temp - type in temp on PID

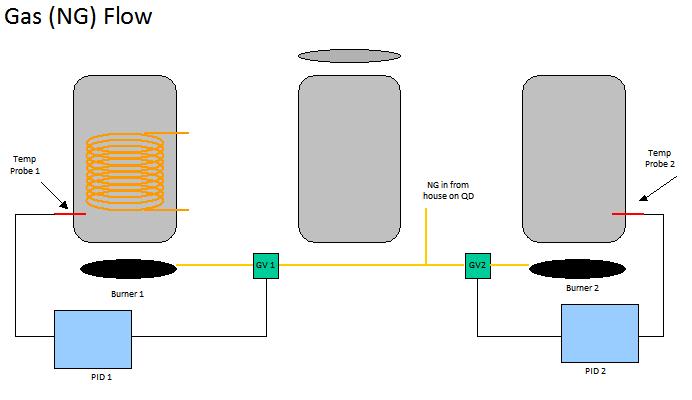

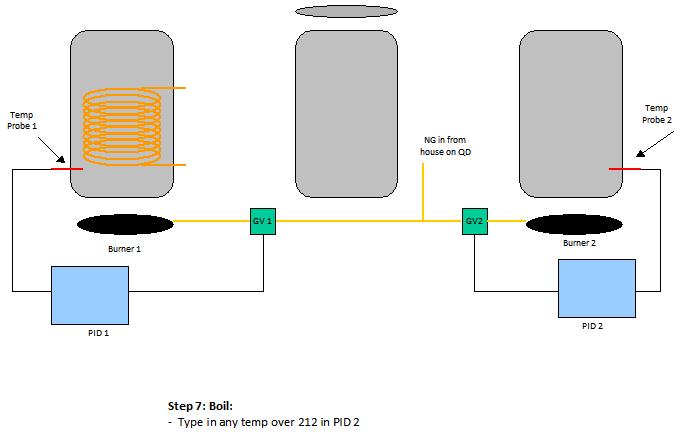

(I have two 32 tip jet burners on pilot and they run off the PIDs)

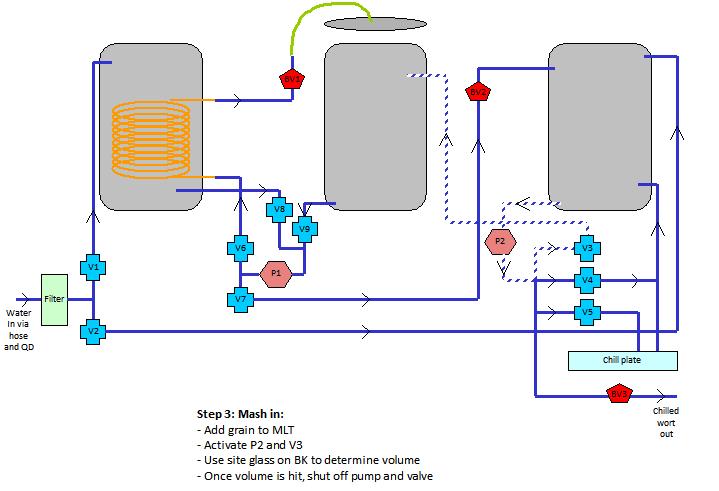

- fill MLT from BK - a switch

- add grain (or simply have grain already in there)

(motorized rake would be needed if going fully automated)

- circulate MLT through heat-ex in HLT - a switch

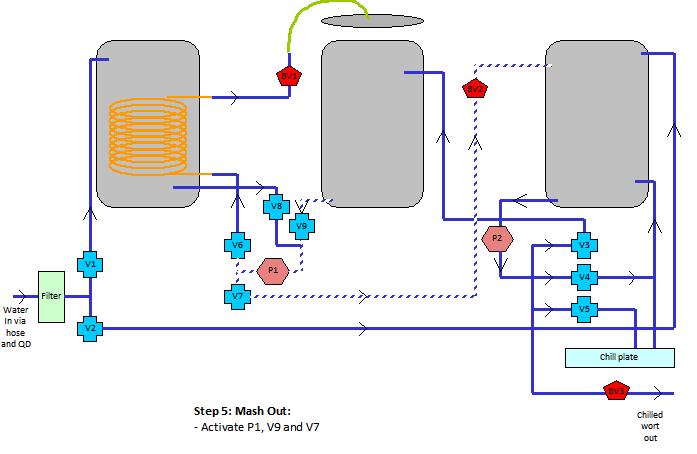

- mash out - a switch

- sparge - a switch

- boil - jack PID up over 212 degrees

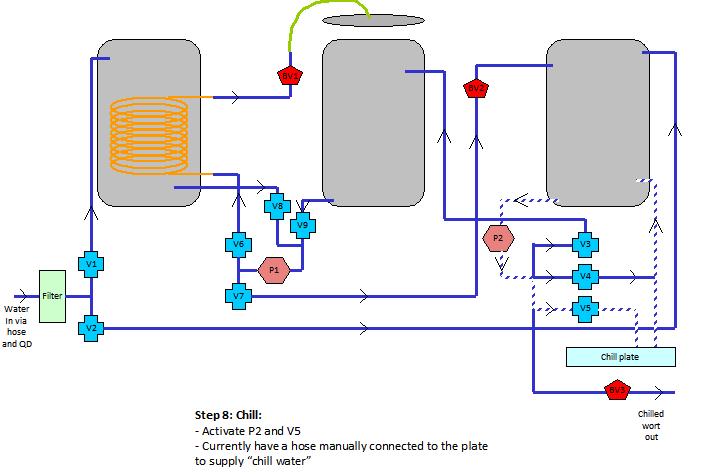

- Chill - a switch (although I would have to have one more solenoid that ran water to the chill plate... right now I hook up a hose manually... so I guess I lied... it's not ALL flip a switch).

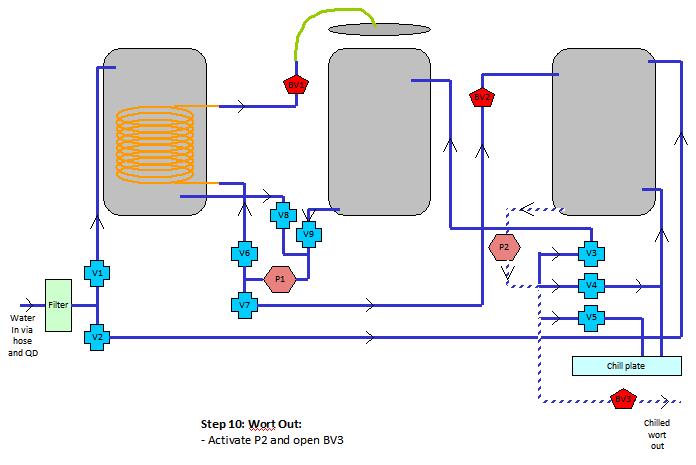

- pump into fementer - a switch.

so I plug a hose into one end... flip a bunch of switches... and cooled wort comes out the other end.

Or are you looking for a schematic?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)