I currently have the Auber PIDs on my 50 amp panel and was wondering if any of you have switched from Auber to Electric Brew Supply PIDs or the other way around. Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Auber PID vs Electric Brew Supply PID

- Thread starter HOPtuary

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Why do you want to change out your PID's? And are they really Auber PID's, or are they EZ-Boils (which do the same job as a PID, but better)?I currently have the Auber PIDs on my 50 amp panel and was wondering if any of you have switched from Auber to Electric Brew Supply PIDs or the other way around. Thanks

Brew on

They are real Auber PIDs. I just feel like they have so many functions and extras that we don't need. I'd like to know if the eBrew Supply PIDs are easier to adjust power to the elements for a easier rolling boil, etc. Just putting a feeler out there mainly.

Why do you want to change out your PID's? And are they really Auber PID's, or are they EZ-Boils (which do the same job as a PID, but better)?

Brew on

The Auber EZ-Boils are easiest to adjust for boil vigor - just turn the knob. They also have a function that allows full power (or a specified percentage of full power) to be applied until a temp just below boiling (user settable temp) and then automatically back off the power to your pre-selected boil power. They also don't usually need tuning to get good mash temp control without overshoot or oscillation issues.

Electric Brew Supply PID's are not going to be any easier to use than Auber PID's.

Brew on

Electric Brew Supply PID's are not going to be any easier to use than Auber PID's.

Brew on

Agree 100% that you should switch from the Auber PID to the Auber EZboil (DSPR-120 or 310)

- Joined

- Oct 6, 2017

- Messages

- 1,704

- Reaction score

- 989

I bought an Electric Brewing panel and swapped out their PID for an EZ Boil before I ever used it.

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

Which model would be the best? I already have probes and ssrs hooked up to my pids. The 300 model?

Agree 100% that you should switch from the Auber PID to the Auber EZboil (DSPR-120 or 310)

Depends on how many extra functions you want the controller to perform. If you are not interested in pre-programmed step mashing, programmable auxiliary relays, or external alarms vs. internal alarms, then you can go with the low end DSPR-120. The higher level systems provide additional functions, that you may or may not need or want.Which model would be the best? I already have probes and ssrs hooked up to my pids. The 300 model?

Brew on

Relative noob here, in regards to electric brewing. I have a pretty simple system and don't need anything fancy. I went with the DSPR-120 and I love it. I find it reasonably intuitive to use and didn't need to adjust anything out of the box. It just works well. Only using to heat strike water and boil control, but it does a good job of bringing the water to temp and keeping where I set it. Nice to be able to just twist the knob for boil power control.

- Joined

- Jul 12, 2017

- Messages

- 489

- Reaction score

- 422

EZBOIL is just that easy! I would never consider any other controller.

So I have a Kal Clone 50 amp setup with some extras on it but for the most part the PIDs have a buzzer and a switch which will mute the buzzer. Other than that one controls the HLT element, another the BK element and the third just displays the mash temp probe and doesnt control any elements. I do step mash but I manually adjust temps for this so a preprogrammed controller isnt necessary. If this would be accomplished with the DSPR-120 then ill put that on my list.

Depends on how many extra functions you want the controller to perform. If you are not interested in pre-programmed step mashing, programmable auxiliary relays, or external alarms vs. internal alarms, then you can go with the low end DSPR-120. The higher level systems provide additional functions, that you may or may not need or want.

Brew on

Are the alarm buzzers and switches separate from the PID, or built into the PID? The DSPR-120 has a built in alarm buzzer, but no provision for connecting to an external buzzer. The DSPR-3x0 series can connect to external alarms, and also have internal alarms.

I would leave the MLT temp monitoring PID alone. An EZ-Boil offers no advantages over a PID for just temperature monitoring.

Brew on

I would leave the MLT temp monitoring PID alone. An EZ-Boil offers no advantages over a PID for just temperature monitoring.

Brew on

Yes the buzzer and switch are external. So sound like in in for 2 new 310s. Maybe a 120 just for for having the same look (damn aesthetics!). Thanks for the help guys.

Are the alarm buzzers and switches separate from the PID, or built into the PID? The DSPR-120 has a built in alarm buzzer, but no provision for connecting to an external buzzer. The DSPR-3x0 series can connect to external alarms, and also have internal alarms.

I would leave the MLT temp monitoring PID alone. An EZ-Boil offers no advantages over a PID for just temperature monitoring.

Brew on

For Mash temps, I use Auber's SYL-2352. It's just a simple temp display unit, capable of displaying temps from two RTDs. It's also slightly cheaper than the DSPR-120 and can tie into an external alarm.

Yes the buzzer and switch are external. So sound like in in for 2 new 310s. Maybe a 120 just for for having the same look (damn aesthetics!). Thanks for the help guys.

I think you only need the EZBoil for the kettle. You aren't trying to adjust the boil in your HERMS/HLT, just set and maintain a temperature.

The SYL-2352 is a regular PID that only accepts 1 RTD input. It costs $41.98. The SYL-2802B is a dual channel (2 RTD inputs) temperature readout. It costs $51.50. A DSPR-120 costs $46.95.For Mash temps, I use Auber's SYL-2352. It's just a simple temp display unit, capable of displaying temps from two RTDs. It's also slightly cheaper than the DSPR-120 and can tie into an external alarm.

Brew on

Last edited:

Very true. I think that is going to be my play here.

I think you only need the EZBoil for the kettle. You aren't trying to adjust the boil in your HERMS/HLT, just set and maintain a temperature.

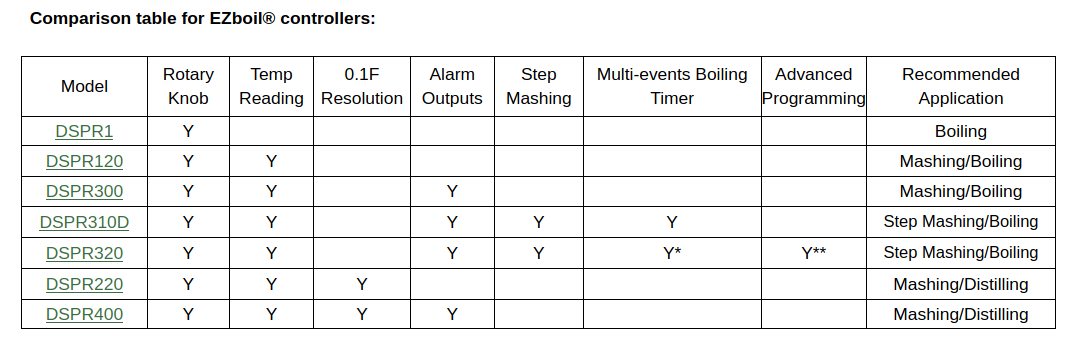

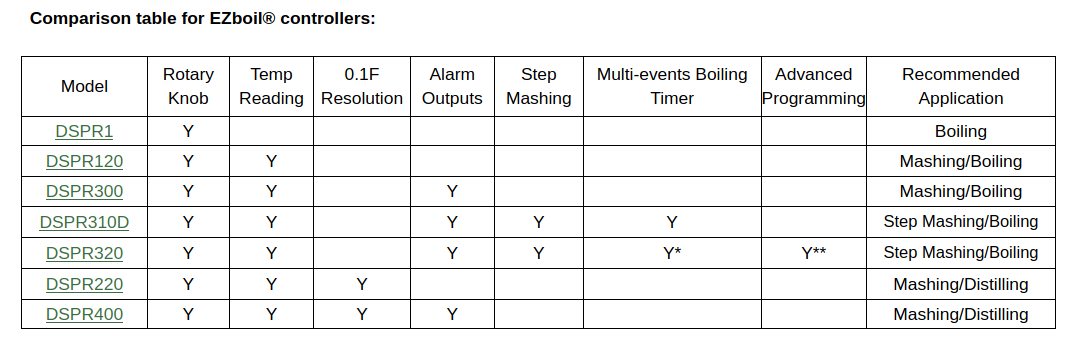

Just for reference: Auber's handy dandy selector chart for EZ-Boils:

The "Step Mashing" column means the unit can do automatic, pre-programmed mash steps. The 120 and 300 can be used for manual stepping (manually setting temp and time for each step, after the previous step completes.)

Brew on

The "Step Mashing" column means the unit can do automatic, pre-programmed mash steps. The 120 and 300 can be used for manual stepping (manually setting temp and time for each step, after the previous step completes.)

Brew on

The Auber EZ-Boils are easiest to adjust for boil vigor - just turn the knob. They also have a function that allows full power (or a specified percentage of full power) to be applied until a temp just below boiling (user settable temp) and then automatically back off the power to your pre-selected boil power. They also don't usually need tuning to get good mash temp control without overshoot or oscillation issues.

Electric Brew Supply PID's are not going to be any easier to use than Auber PID's.

Brew on

I'm in a nearby boat; thinking of changing from CraftbeerPi to hardware PID's and the EZboil caught my eye.

Does this mean that I can manually control the PWM duty cycle with the EZ boil? For example, I have enough juice to run both my elements simultaneously, but I still worry that my chiller, fridge, freezer might start up and pop the breaker. So when I'm sparging I set both BK and HLT elements to 50% just to lighten the load until I can turn the HLT off completely.

Is this also possible with the DSPR 120 and 300?

cheers

All the DSPRs will allow you to set max power output for boiling heat up acceleration mode, but only the 320 allows max power output for mash temp heat up acceleration mode. It's the latter that you would want to use on your HLT.I'm in a nearby boat; thinking of changing from CraftbeerPi to hardware PID's and the EZboil caught my eye.

Does this mean that I can manually control the PWM duty cycle with the EZ boil? For example, I have enough juice to run both my elements simultaneously, but I still worry that my chiller, fridge, freezer might start up and pop the breaker. So when I'm sparging I set both BK and HLT elements to 50% just to lighten the load until I can turn the HLT off completely.

Is this also possible with the DSPR 120 and 300?

cheers

You shouldn't have to worry about your breaker tripping, if you have all those other loads you mentioned on separate circuits from the main breaker panel. You should never plug more than your brew control panel into the power circuit that feeds it.

Brew on

Similar threads

- Replies

- 1

- Views

- 525

Latest posts

-

-

Pilsner Malt Comparison: Rahr vs. Weyermann vs. Great Western vs. Viking

- Latest: FranklinsBeerTower

-

-

-

-