magnj

Well-Known Member

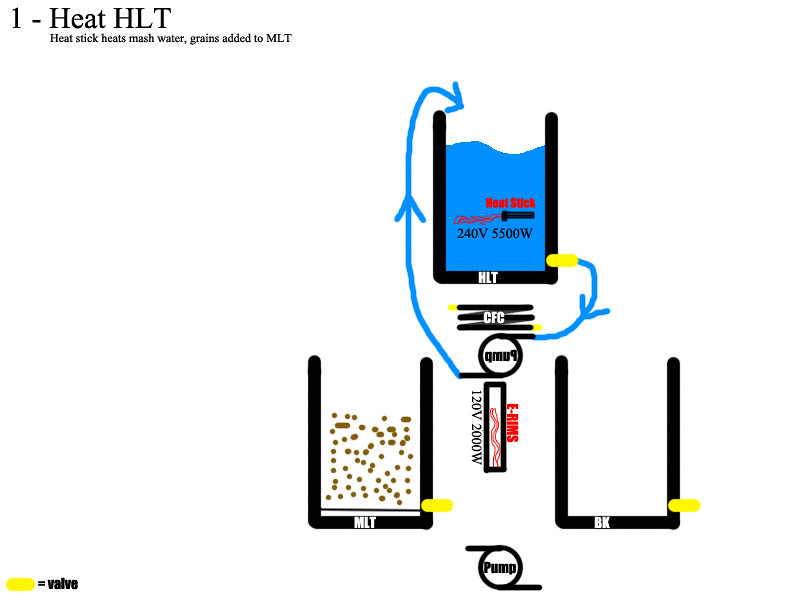

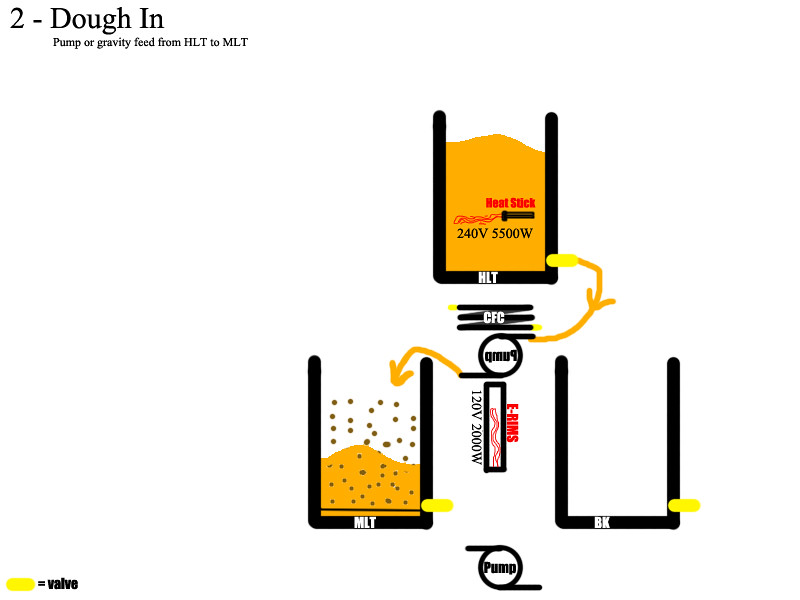

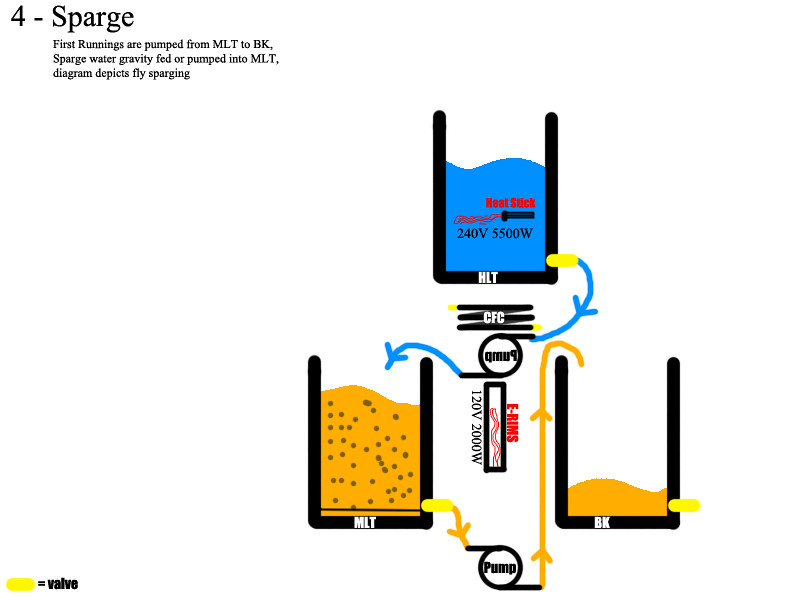

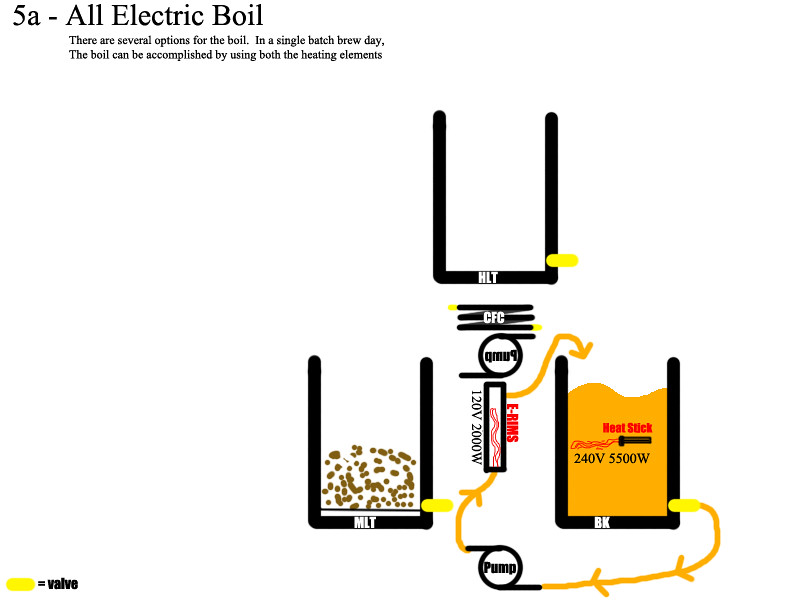

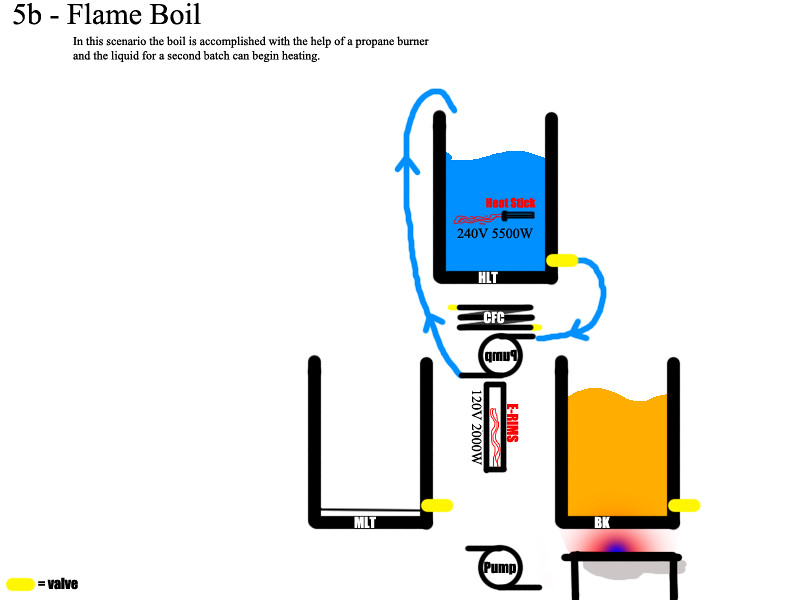

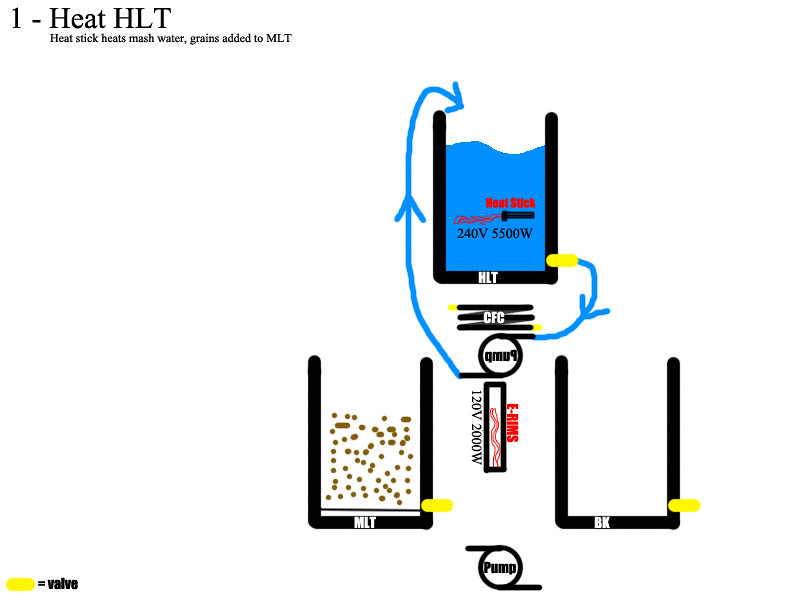

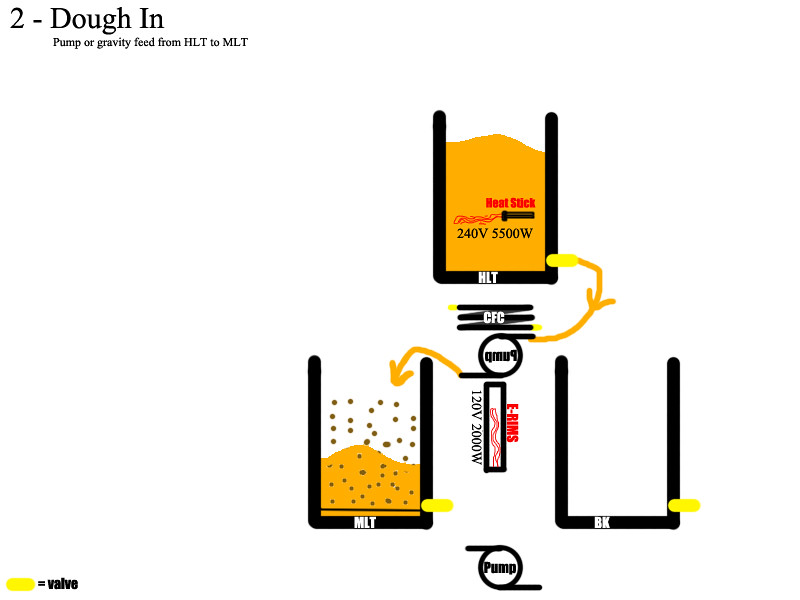

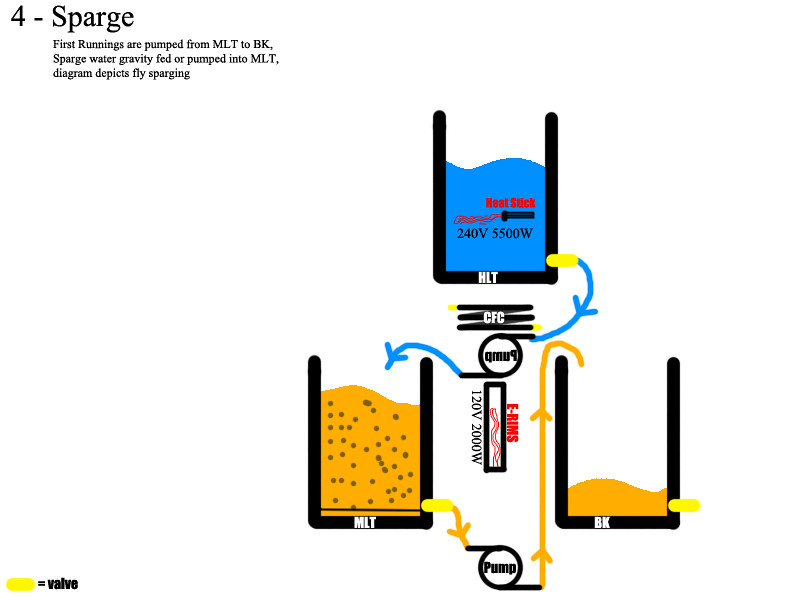

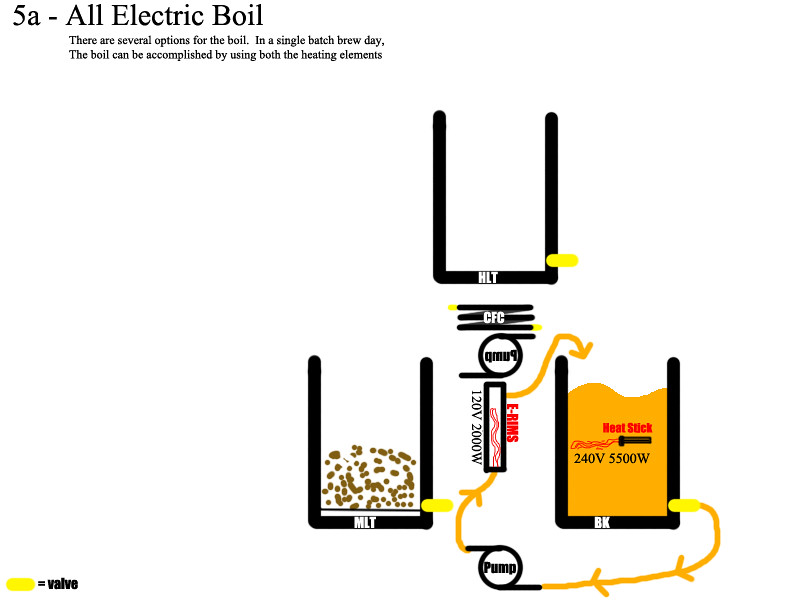

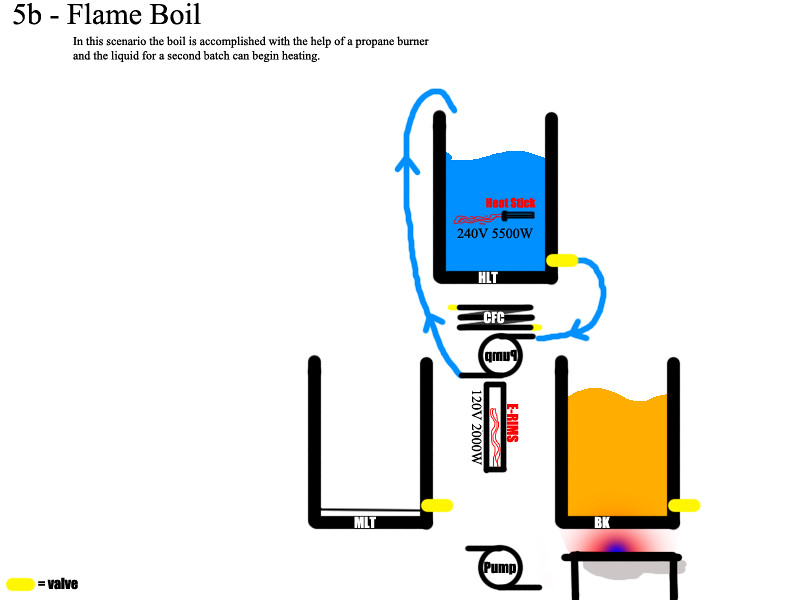

I'm designing an electric 10 Gallon brewery and I'm thinking of doing a 5500W 240V heatstick hooked to a PID or Brewtroller to heat the HLT and possibly boil. I'm looking at the Camco 02933 . Is this smart? Is this dumb? If I recirculate the HLT with a pump and if I recirculate the wort in the same way during the boil will I have any issues evenly heating and avoiding scorching? The rationale of the heatstick being I can either keep it in the HLT to heat up the mash water for a second batch and boil with propane or move it to the BK and boil with or without the RIMS tube...

Last edited by a moderator:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)