- Joined

- Feb 10, 2016

- Messages

- 107

- Reaction score

- 79

Hey all,

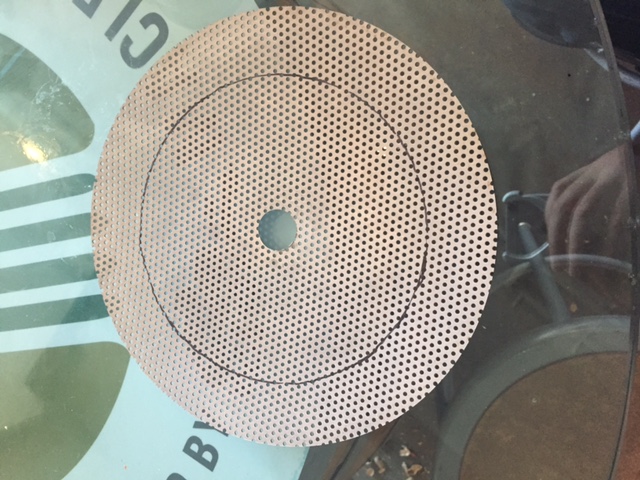

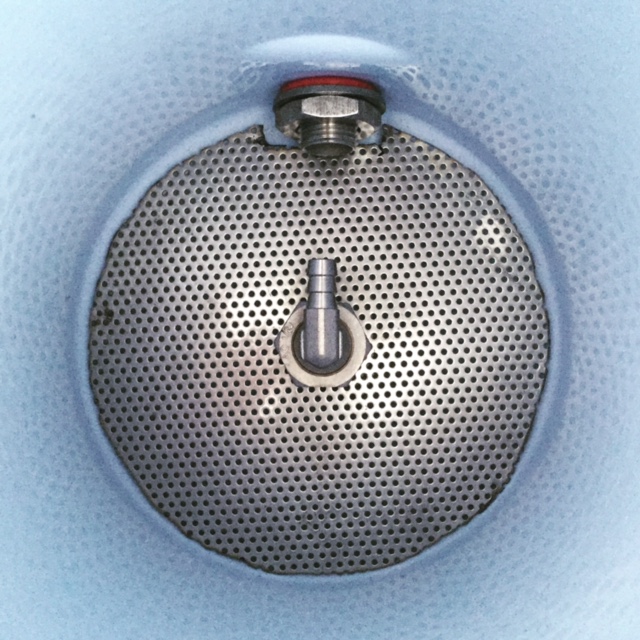

I've just installed a proper false bottom into my mash tun, and as I already have a HLT and sparge arm, I've started fly sparging my mashes. Now, as I'll be shortly purchasing a nice little SS pump, I've begun to think about recirculation during the mash, and potentially during the sparge. But here's the catch: I am a young brewer (22, don't worry), and as I live in my parents' house, I'm restricted to one gallon batches. So continuous sparging has proven difficult, as the drip rate appropriate to continuous sparging causes my "wort aerator" sparge attachment to produce a single drip in the center of the tun.

Now, any sane person would say, "why not just BIAB every beer, and ditch the false bottom? For that matter, even if you wanted a higher efficiency for the odd high gravity beer which could pose volume constraints on your tun, why not batch sparge?" But I brew primarily for the engineering challenge it poses, and my goal is to hit 90% efficiency with my one gallon setup, so until I'm convinced that it's wildly impractical to continuously sparge, I will pursue that goal.

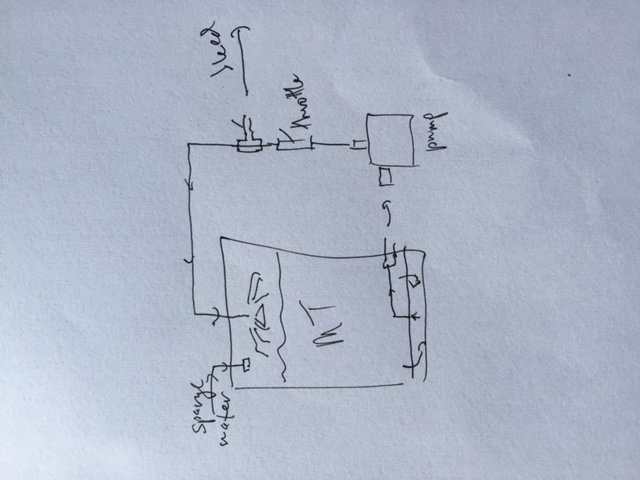

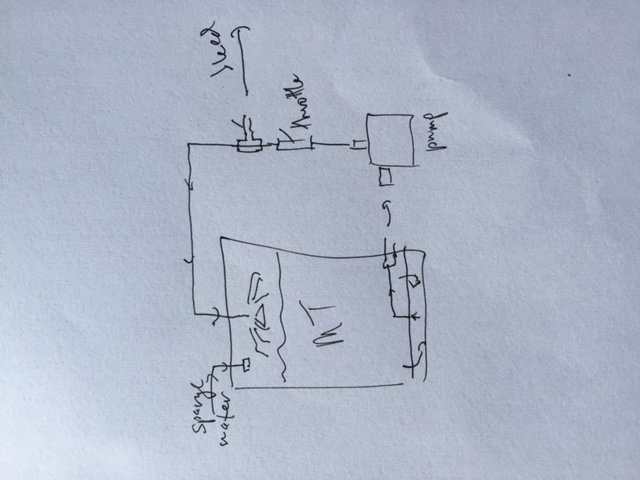

So, the idea: instead of simply adding sparge water to the top and hoping it effectively rinses the grain bed in one pass, why not take a note from our distilling friends, and fabricate a "forced reflux" HLT, wherein a pump constantly recirculates the wort, and a valve is introduced downstream of the pump to "bleed" a small portion of the wort continuously, while fresh sparge water is added to the top of the tun to replace the displaced, bled wort? This would allow me to produce a very even drip pattern atop the entire grain bed, but the efficiency of rerunning the wort through the grains, let alone the efficiency of quickly vs slowly running the sparge water past the grains, are things I do not understand well enough to know if this is a very good idea, or a very bad idea. I've never heard of it being done, but that's possibly because it would be very impractical for anything above a few gallons

The logistics of this are mercifully simple, my questions are this: is this more efficient than batch sparging? Would recirculating already sugar-rich wort back through the grain bed kill the efficiency of fly sparging for some reason? At what point do the grains "catch" more sugars, if that's even how that would work, than they leech into the wort? In short, the absurd impracticality of this endeavor aside, would this be more or as efficient as batch sparging? Also, the alternative to achieve a uniform sparge spread would be the drill very small holes in a rotating or non-rotating piece of small ID soft copper tubing, which I have a length of lying around - I will certainly be trying this solution

Thanks in advance for your feedback!

I've just installed a proper false bottom into my mash tun, and as I already have a HLT and sparge arm, I've started fly sparging my mashes. Now, as I'll be shortly purchasing a nice little SS pump, I've begun to think about recirculation during the mash, and potentially during the sparge. But here's the catch: I am a young brewer (22, don't worry), and as I live in my parents' house, I'm restricted to one gallon batches. So continuous sparging has proven difficult, as the drip rate appropriate to continuous sparging causes my "wort aerator" sparge attachment to produce a single drip in the center of the tun.

Now, any sane person would say, "why not just BIAB every beer, and ditch the false bottom? For that matter, even if you wanted a higher efficiency for the odd high gravity beer which could pose volume constraints on your tun, why not batch sparge?" But I brew primarily for the engineering challenge it poses, and my goal is to hit 90% efficiency with my one gallon setup, so until I'm convinced that it's wildly impractical to continuously sparge, I will pursue that goal.

So, the idea: instead of simply adding sparge water to the top and hoping it effectively rinses the grain bed in one pass, why not take a note from our distilling friends, and fabricate a "forced reflux" HLT, wherein a pump constantly recirculates the wort, and a valve is introduced downstream of the pump to "bleed" a small portion of the wort continuously, while fresh sparge water is added to the top of the tun to replace the displaced, bled wort? This would allow me to produce a very even drip pattern atop the entire grain bed, but the efficiency of rerunning the wort through the grains, let alone the efficiency of quickly vs slowly running the sparge water past the grains, are things I do not understand well enough to know if this is a very good idea, or a very bad idea. I've never heard of it being done, but that's possibly because it would be very impractical for anything above a few gallons

The logistics of this are mercifully simple, my questions are this: is this more efficient than batch sparging? Would recirculating already sugar-rich wort back through the grain bed kill the efficiency of fly sparging for some reason? At what point do the grains "catch" more sugars, if that's even how that would work, than they leech into the wort? In short, the absurd impracticality of this endeavor aside, would this be more or as efficient as batch sparging? Also, the alternative to achieve a uniform sparge spread would be the drill very small holes in a rotating or non-rotating piece of small ID soft copper tubing, which I have a length of lying around - I will certainly be trying this solution

Thanks in advance for your feedback!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)