AG3

Member

Hello everyone! First post here!

I've been working on an all-grain system design with some level of automation in mind and I'd appreciate any input before I move onto the detailed design and start ordering components. I currently live in an apartment with limited space and a stove not worthy of larger batches, so I'm planning to go with an electric setup in a vertical configuration. The goal is to brew 5 and 10 gallon batches using only one pump, one heating element, limited number of valves, and minimal hose changes. I'd also like to maintain some level of portability and keep the smallest storage footprint possible. On to the design!

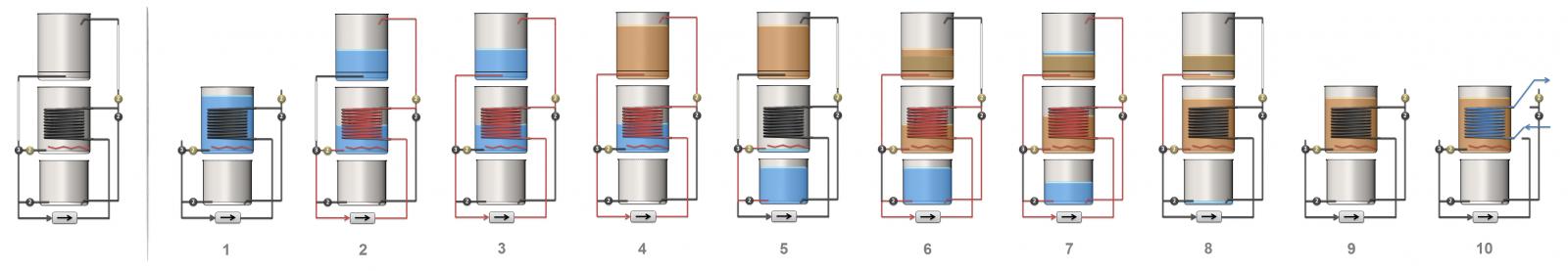

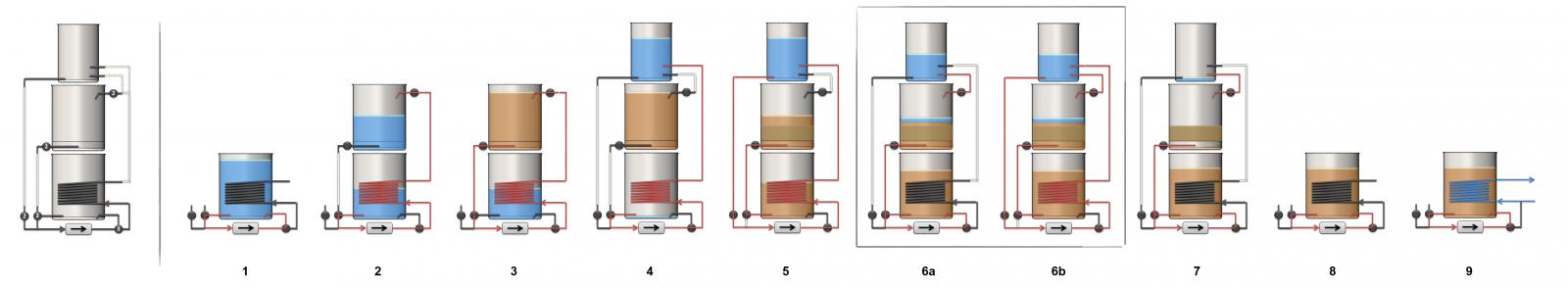

I attached an image of the flow diagram, but I believe the size was reduced which removed some detail, so here is a link to a public Dropbox image if you'd like to take a closer look: Flow Diagram

The first image is the system completely assembled. The numbers on the valves (dark gray circles) tell what type of valve each is (2-way or 3-way ball valve). I was planning to use motorized valves; however, two of the valves will probably need to made out of a standard ball valve and a servo motor to provide flow control. From what I've seen, all affordable motorized ball valves only have on/off states. The black lines are fixed stainless tubing, the white lines are silicon tubing with cam locks or tri clovers (haven't decided yet). Finally, the dashed lines represent the one hose swap that will be required. The heat exchanger is a 1/2" x 50ft stainless coil, fixed inside the lowest kettle just above the heating element and used for a HERMS system, maintaining sparge water temps, and wort chilling.

The remaining 9 images show how I expect the typical brew process to flow. I'll list a brief description of each step, but hopefully it's clear from the diagram. The red lines show the paths that have water or wort running through them.

Step 1: Bring water up to strike temperatures. Hopefully enough water for mashing and sparging, but additional water can be added to the sparge pot if necessary.

Step 2: Stack mash tun on boil kettle and connect two lines. Transfer required amount of water up to mash tun.

Step 3: Recirculate water in mash tun to bring back up to strike temperatures if they dropped and preheat the mash tun. Once temperatures are correct, add grains and begin mash process. The remaining water in the boil kettle will be used to maintain mash temperatures as a HERMS system.

Step 4: After mashing, stack sparge pot on top of mash tun. Move line from input of mash tun to input of sparge pot and make other connections shown. After mashing, transfer remaining water in boil kettle up to sparge pot.

Step 5: Drain wort into boil kettle leaving an inch or so above the top of grain bed. Once enough wort is in boil kettle, heat wort and recirculate sparge water to maintain temperatures.

Step 6a and 6b: Sparge. Adjust the two ball valves to match wort out and sparge in flow rates, maintaining an inch or so of water over the grain bed. If sparge temperatures drop, close boil kettle recirculation path and recirculate sparge water to bring back up to temp. I don't expect this to be required too often but the capability is there.

Step 7: Sparge completed.

Step 8: Remove sparge pot and mash tun. Boil.

Step 9: Chill wort. Use an outdoor hose or sink faucet adapter to push cold water through the coils for initial cooling. If necessary, after initial cooling, a cheap pump can push ice water through the coils from the mash tun pot once cleaned. The main pump continuously runs to create a whirlpool for faster cooling.

Hopefully that gives you the general idea!

A few questions I have:

1.) Do you see any issues with not being able to access any pots below the highest pot. This would be the boil kettle while mashing, and the mash tun while sparging. There may be enough room to see what's going on but it will be pretty limited.

2.) Do you see any limitations to the system? Any methods or techniques this would not allow? I'd like to keep options open to try different methods of mashing, sparging, etc.

3.) Any thoughts? Pros, cons, etc.

Thanks everyone! I'm excited to be a part of this awesome community and looking forward to your inputs!

I've been working on an all-grain system design with some level of automation in mind and I'd appreciate any input before I move onto the detailed design and start ordering components. I currently live in an apartment with limited space and a stove not worthy of larger batches, so I'm planning to go with an electric setup in a vertical configuration. The goal is to brew 5 and 10 gallon batches using only one pump, one heating element, limited number of valves, and minimal hose changes. I'd also like to maintain some level of portability and keep the smallest storage footprint possible. On to the design!

I attached an image of the flow diagram, but I believe the size was reduced which removed some detail, so here is a link to a public Dropbox image if you'd like to take a closer look: Flow Diagram

The first image is the system completely assembled. The numbers on the valves (dark gray circles) tell what type of valve each is (2-way or 3-way ball valve). I was planning to use motorized valves; however, two of the valves will probably need to made out of a standard ball valve and a servo motor to provide flow control. From what I've seen, all affordable motorized ball valves only have on/off states. The black lines are fixed stainless tubing, the white lines are silicon tubing with cam locks or tri clovers (haven't decided yet). Finally, the dashed lines represent the one hose swap that will be required. The heat exchanger is a 1/2" x 50ft stainless coil, fixed inside the lowest kettle just above the heating element and used for a HERMS system, maintaining sparge water temps, and wort chilling.

The remaining 9 images show how I expect the typical brew process to flow. I'll list a brief description of each step, but hopefully it's clear from the diagram. The red lines show the paths that have water or wort running through them.

Step 1: Bring water up to strike temperatures. Hopefully enough water for mashing and sparging, but additional water can be added to the sparge pot if necessary.

Step 2: Stack mash tun on boil kettle and connect two lines. Transfer required amount of water up to mash tun.

Step 3: Recirculate water in mash tun to bring back up to strike temperatures if they dropped and preheat the mash tun. Once temperatures are correct, add grains and begin mash process. The remaining water in the boil kettle will be used to maintain mash temperatures as a HERMS system.

Step 4: After mashing, stack sparge pot on top of mash tun. Move line from input of mash tun to input of sparge pot and make other connections shown. After mashing, transfer remaining water in boil kettle up to sparge pot.

Step 5: Drain wort into boil kettle leaving an inch or so above the top of grain bed. Once enough wort is in boil kettle, heat wort and recirculate sparge water to maintain temperatures.

Step 6a and 6b: Sparge. Adjust the two ball valves to match wort out and sparge in flow rates, maintaining an inch or so of water over the grain bed. If sparge temperatures drop, close boil kettle recirculation path and recirculate sparge water to bring back up to temp. I don't expect this to be required too often but the capability is there.

Step 7: Sparge completed.

Step 8: Remove sparge pot and mash tun. Boil.

Step 9: Chill wort. Use an outdoor hose or sink faucet adapter to push cold water through the coils for initial cooling. If necessary, after initial cooling, a cheap pump can push ice water through the coils from the mash tun pot once cleaned. The main pump continuously runs to create a whirlpool for faster cooling.

Hopefully that gives you the general idea!

A few questions I have:

1.) Do you see any issues with not being able to access any pots below the highest pot. This would be the boil kettle while mashing, and the mash tun while sparging. There may be enough room to see what's going on but it will be pretty limited.

2.) Do you see any limitations to the system? Any methods or techniques this would not allow? I'd like to keep options open to try different methods of mashing, sparging, etc.

3.) Any thoughts? Pros, cons, etc.

Thanks everyone! I'm excited to be a part of this awesome community and looking forward to your inputs!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)