scottballz

Well-Known Member

Hey guys,

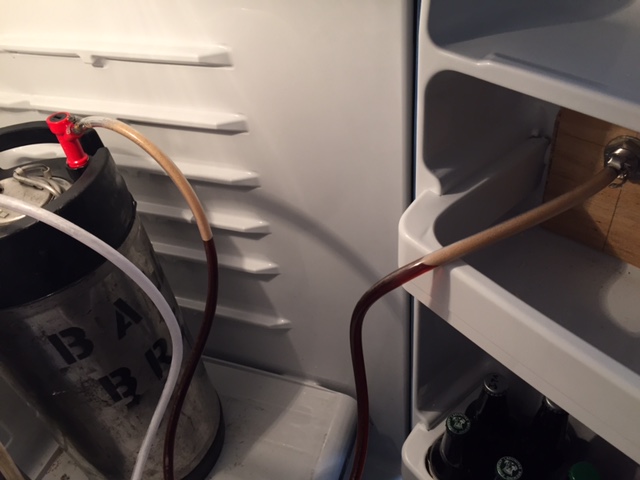

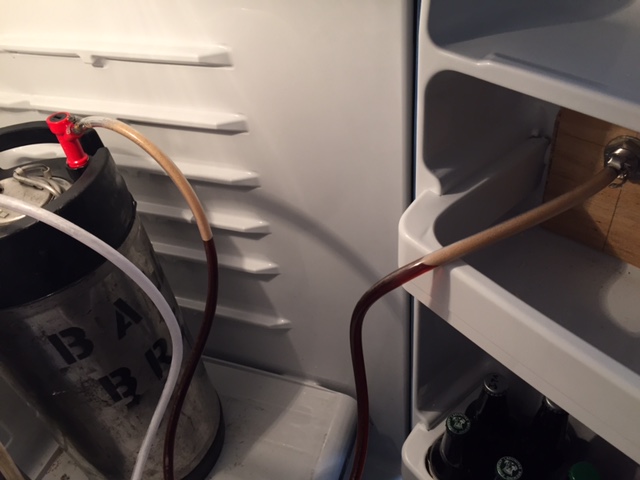

I have been having problems with one keg in particular. It seems I'm getting air pockets in the line. one at the post and one at the faucet. the same thing happened with a ginger beer I made that was hooked up to another faucet but was in the same keg which makes me think it is something wrong with the keg itself. I also just replaced the line and put in a brand new Perla faucet. you can see the air pockets in the picture.

-The line itself is only about 6 ft long

-the beer is a homemade chocolate stout

-I forced carbed 2 days ago at 25psi for 1 min while rocking it at 42 f

-I released the pressure from the keg before hooking it up to 9 psi for serving

-the temp in the kegorator is 42 f.

I really dont think any of this is playing a factor but just in case this is hopefully all the info. I also have an IPA on tap that I did the exact same way on the tap next to it which is pouring just fine.

I have been having problems with one keg in particular. It seems I'm getting air pockets in the line. one at the post and one at the faucet. the same thing happened with a ginger beer I made that was hooked up to another faucet but was in the same keg which makes me think it is something wrong with the keg itself. I also just replaced the line and put in a brand new Perla faucet. you can see the air pockets in the picture.

-The line itself is only about 6 ft long

-the beer is a homemade chocolate stout

-I forced carbed 2 days ago at 25psi for 1 min while rocking it at 42 f

-I released the pressure from the keg before hooking it up to 9 psi for serving

-the temp in the kegorator is 42 f.

I really dont think any of this is playing a factor but just in case this is hopefully all the info. I also have an IPA on tap that I did the exact same way on the tap next to it which is pouring just fine.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)