surreal_trip

Well-Known Member

Needed or not? I'm wondering how you gents have gotten the breeze a movin inside your kegerators and keezers... Their's a lot of ideas out there! Lets hear yours!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

With no fans or underpowered fans, the compressor would go out about 6-8 times a day for about 1-2 hours each. It now goes on about 10 times a day, but for about 30 minutes each. I would assume this means less stratification and less work by the compressor to remove warmth. This should translate to a slightly lower operating cost.

The planned test runs will be:

1. With fan running continuously and no insulation on the collar

2. Without fan running and no insulation on the collar

3. With fan running continuously and with insulated collar

4. Without fan running and with insulated collar

I'll log the ambient room temperature and the duration of the compressor on/off periods. I haven't decided on what type of insulation to use, but it will probably be the rigid foam stuff.

IMO, with the fan the cooling is much more uniform, but at the expense of the compressor running more and using more power.

That would be a fantastic experiment. It would be better if you keep the room temperature steady to minimize the influencing variables. If the freezer is in the garage and it can't be moved inside, I'm afraid that temperature oscillation in the garage will have a considerable impact in your results, you will need a huge sampling to compensate that.

I do believe, regardless of presence or absence of collar insulation, that a continuously running fan will always cause the condenser to go off more often.

I think having a fan always on is a mistake. If the fan can be wired to the "switch on" source (in the thermostat or controller) and be triggered only when the compressor is running, that would likely reduce the frequency of the compressor being triggered and would still provide the benefits of circulating air inside, which is to keep the lines cool and beer temps more uniform inside the kegs.

Right, only a refrigeration engineer or experienced technician could settle this argument, but my observations from other blogs about refrigeration set-ups for camping or RVs suggest that running a fan continuously, even a small computer fan, inside a sealed compartment like a chest freezer is a bad idea. An internal fan will struggle to suck air from every corner and dead space that is not sealed, bringing in heat. In addition, the little motor gets warm trying to find enough air to function and releases heat too. In fact, the reason why the compressor is working more is because it needs more working power to compensate for the heat brought in by the fan. Yes, a continuously running fan will surely keep air well distributed all the time and steady temps for lines and keg, but heck, it will also short your compressor life significantly and considerably increase your energy waste. The benefit of air distribution with a fan inside a freezer is only efficient when the fan is allowed to work for limited periods of time and from what I learned, it can actually be very beneficial in that way.

I think other people here have hooked their internal computer fans to the controller or thermostat for better efficiency.

My argument would be that even though the compressor cycles more often with a fan, this air movement makes this more efficient operation...thus shorter compressor cycles.

It may not be cheaper to run as any electric motor requires a lot more power at startup than at continuous operation, but compressor activity is I think the biggest power draw here.

Still, I simply can't run my keez with the fan off, coffin temps go to high and foam ensues...so the point is moot for me.

Right, only a refrigeration engineer or experienced technician could settle this argument, but my observations from other blogs about refrigeration set-ups for camping or RVs suggest that running a fan continuously, even a small computer fan, inside a sealed compartment like a chest freezer is a bad idea. An internal fan will struggle to suck air from every corner and dead space that is not sealed, bringing in heat. In addition, the little motor gets warm trying to find enough air to function and releases heat too. In fact, the reason why the compressor is working more is because it needs more working power to compensate for the heat brought in by the fan. Yes, a continuously running fan will surely keep air well distributed all the time and steady temps for lines and keg, but heck, it will also short your compressor life significantly and considerably increase your energy waste. The benefit of air distribution with a fan inside a freezer is only efficient when the fan is allowed to work for limited periods of time and from what I learned, it can actually be very beneficial in that way.

I think other people here have hooked their internal computer fans to the controller or thermostat for better efficiency.

I am sorry but I have to ask...do you have a keezer and are speaking from experience, or are you referring to hearsay from other forums? I read dozens of keezer threads here, and I don't know of any that successfully have their fan cycling on and off. If I am mistaken, please find us some examples from HBT.

I don't mean to sound like a tool, but only real world experience or actual scientific analysis is going to answer this type of question...anything else is just fud.

The Love controller provides switched power on the green wire which is connected by a yellow wire nut to the compressor and to the last prong on the wall bug. This allows the fan to run when the compressor runs, and stop when the compressor stops. I like this rather than having it run all the time because the electrical energy given to the fan is dissipated as heat inside the kegerator, making it less efficient.

He may have a good looking keez, but both Love and Johnson advise keeping their probes out of water. Sometimes, things works in spite of their design...not because of it.

If we are using fans to break up stratification...Then why allow the keezer to become stratified at all? In other words, why cycle the fan OFF when the compressor is OFF? To save from heat buildup? I just don't think it's a concern in a forty degree space with gallons of cold beer, metal, etc.

The subject of probe in the water is also debatable... manufacturers recommend to leave them out of water to simply avoid damage, but on that respect, I actually know from experience that the Love prove will not damage if kept under water...

SOME Love probes maybe. Mine died after a few months - I got an error code, I called Dwyer - they said "Probe Error."

So now I slide them into a sleeve of hobby-shop brass, epoxy the ends, and I'm golden.

If we are using fans to break up stratification...Then why allow the keezer to become stratified at all? In other words, why cycle the fan OFF when the compressor is OFF? To save from heat buildup? I just don't think it's a concern in a forty degree space with gallons of cold beer, metal, etc.

My love probe is in water. (Hmmm) I didn't know that wasn't recommended by Dwyer. I may encase it in something to protect it like Hang Glider did. Before I put it in water, the temperature swings occurred more rapidly causing the compressor to cycle more frequently.

But I'm still experimenting to find the best setup. My controller hysteresis is set to 3 degrees. I think that setting it to 5 degrees would reduce compressor cycling frequency but cause the compressor to run longer. That might actually be more desirable from both an energy consumption perspective and compressor service life. I don't like the idea of my beer temperature changing that much though.

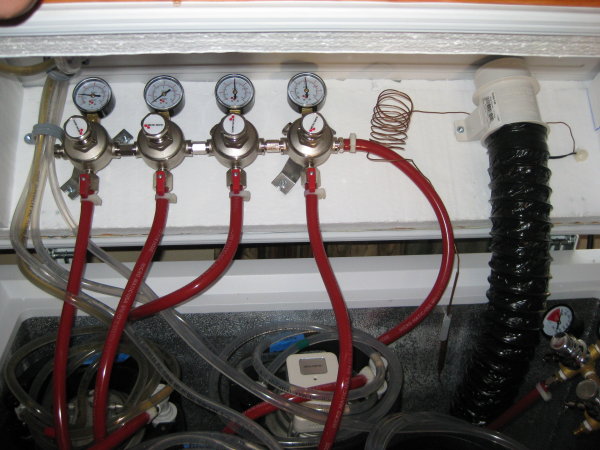

I have not yet insulated my collar. I really like the hangar bolts that Quaffer used to hang his manifolds. He's got a few other good ideas in that thread too.

I agree. Seems counterproductive to set it up to increase the temperature stratification when the desired effect is just the opposite. The heat generated by a muffin fan is negligible IMO. Mine doesn't even get warm to the touch when run outside of the freezer. Sure, it's an electric motor and it will generate some heat, but we're talking about a very, very tiny amount of heat. Relative to the heat infiltrating a freezer it's not even worth considering and I doubt you would be able to even measure the difference without some highly sophisticated test equipment.

IMO, putting a temp probe in a container of water is not the way to go. All it will do is increase the controller response time and widen the temperature swings. You could do the same by simply setting the controller differential higher.

I picked up the insulation for the collar today. I bought the 3/4" polystyrene foam without the foil backing. It should help immensely with the heat gain through the collar. It may be several days before I can get the testing done, but stay tuned for further developments.

Like you said, it avoid temperatures swings since the hot air coming in when you open the keezer door don't affect the water temperature much. That saves you compressor work, i.e. less energy waste and more life time for the compressor.

So, how do you plan to measure air distribution or temperature distribution throughout different parts of the keezer in your experiment? Isn't the whole point of having a fan running continuously about improving air distribution and assure even distribution of temperature for lines and keg at the expense of more compressor work? I mean, just measuring how many times or duration of compressor cycles with or without the fan is not going to tell much, am I wrong? I guess it would be good put some numbers to prove facts we already know.