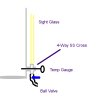

Call me crazy. I have four keggles, each with one 1/2" NPT fitting. I'd love to have temp, ball valve, and a sight glass, but don't particularly want to drill and weld new holes. It seems to me that I could simply buy a standard 4-Way Stainless Steel keg cross:

https://www.homebrewing.org/SS-12-NPT-4-way-cross-_p_2929.html

Then run the sight tube out of the top, the temp gauge in the side, and the ball valve out of the bottom. Has anyone done this? Is there a problem I'm not seeing?

https://www.homebrewing.org/SS-12-NPT-4-way-cross-_p_2929.html

Then run the sight tube out of the top, the temp gauge in the side, and the ball valve out of the bottom. Has anyone done this? Is there a problem I'm not seeing?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)