augiedoggy

Well-Known Member

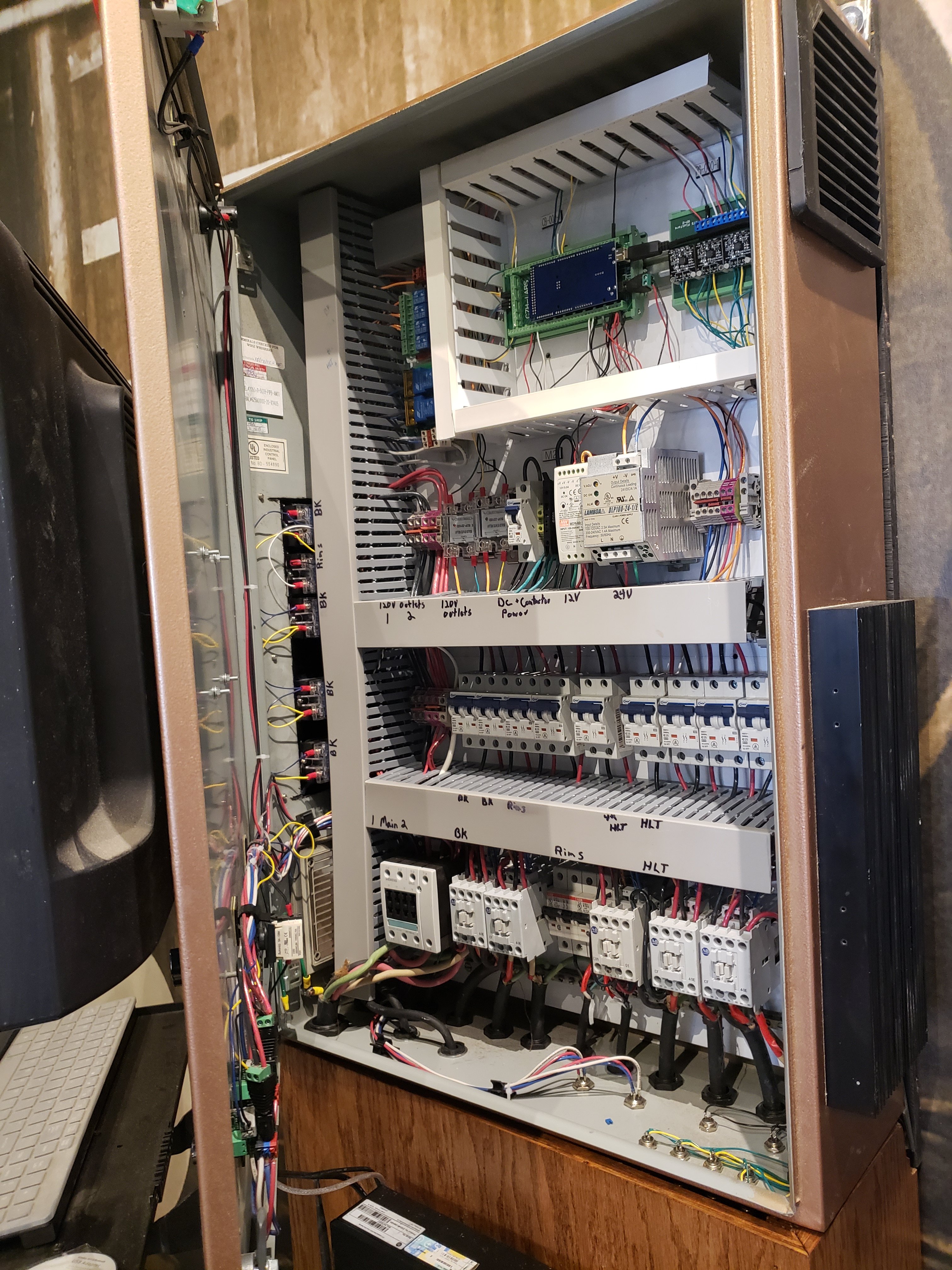

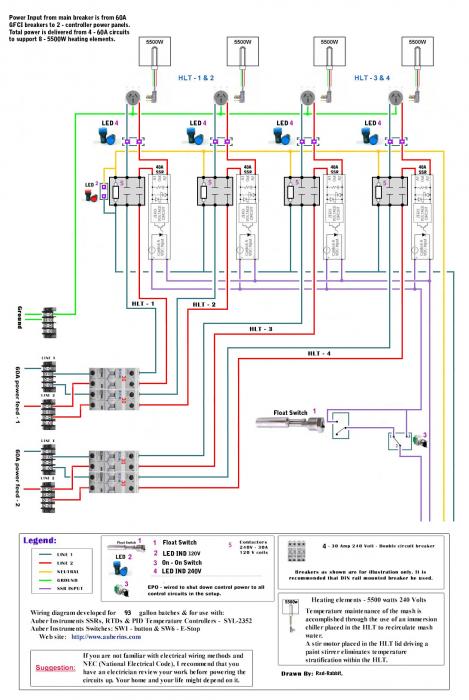

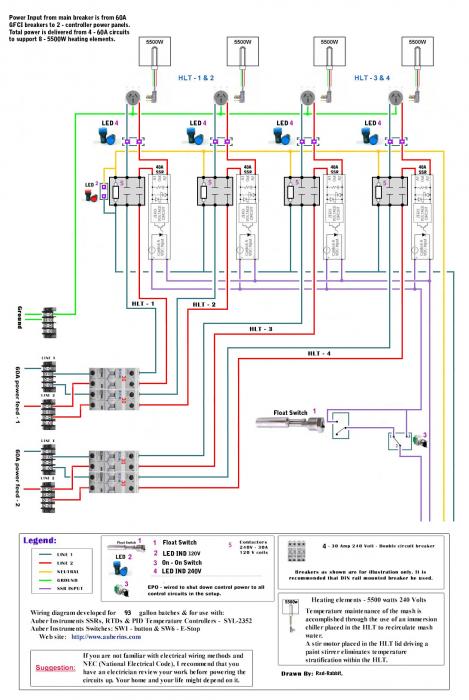

Hello, I'm hoping someone might have or be able to assist me in acquiring a 3 bbl wiring diagram like the one linked below in higher resolution... I intend on having 4 5500w elements in the boil and 4 in the HLT and the wiring will be identical for each separate electrical box except im going to install a float switch for the HLT I do intend on using din breakers for each element as well as contactors and separate SSR's I dont need the wiring for pids as that is all going to be in a separat low voltage panel using brucontrol.

I dont really need the indicator lights for each element below.

I am also going to be using a 240v rims.

I know how to wire it but I know nothing of the programs that draw the diagrams and I want something professional looking to follow and submit to the electrical inspector.

I dont really need the indicator lights for each element below.

I am also going to be using a 240v rims.

I know how to wire it but I know nothing of the programs that draw the diagrams and I want something professional looking to follow and submit to the electrical inspector.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)